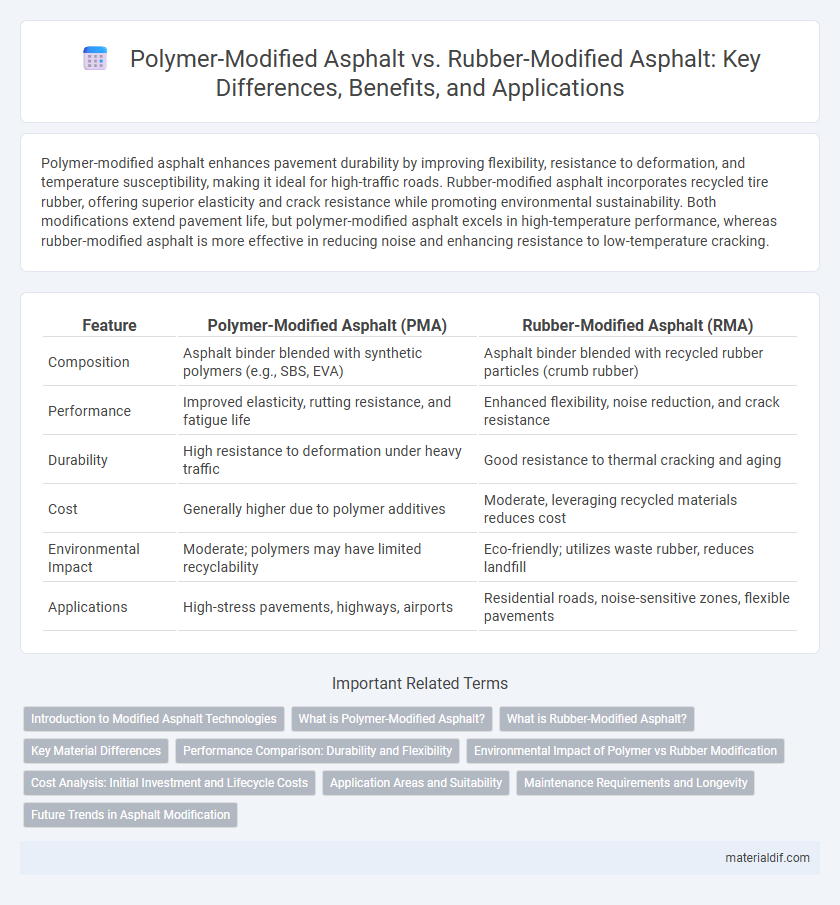

Polymer-modified asphalt enhances pavement durability by improving flexibility, resistance to deformation, and temperature susceptibility, making it ideal for high-traffic roads. Rubber-modified asphalt incorporates recycled tire rubber, offering superior elasticity and crack resistance while promoting environmental sustainability. Both modifications extend pavement life, but polymer-modified asphalt excels in high-temperature performance, whereas rubber-modified asphalt is more effective in reducing noise and enhancing resistance to low-temperature cracking.

Table of Comparison

| Feature | Polymer-Modified Asphalt (PMA) | Rubber-Modified Asphalt (RMA) |

|---|---|---|

| Composition | Asphalt binder blended with synthetic polymers (e.g., SBS, EVA) | Asphalt binder blended with recycled rubber particles (crumb rubber) |

| Performance | Improved elasticity, rutting resistance, and fatigue life | Enhanced flexibility, noise reduction, and crack resistance |

| Durability | High resistance to deformation under heavy traffic | Good resistance to thermal cracking and aging |

| Cost | Generally higher due to polymer additives | Moderate, leveraging recycled materials reduces cost |

| Environmental Impact | Moderate; polymers may have limited recyclability | Eco-friendly; utilizes waste rubber, reduces landfill |

| Applications | High-stress pavements, highways, airports | Residential roads, noise-sensitive zones, flexible pavements |

Introduction to Modified Asphalt Technologies

Polymer-modified asphalt (PMA) and rubber-modified asphalt (RMA) represent advanced technologies enhancing traditional asphalt binder performance through the incorporation of polymers and recycled rubber, respectively. PMA improves elasticity, rutting resistance, and durability by integrating materials such as styrene-butadiene-styrene (SBS) polymers, while RMA enhances flexibility and temperature susceptibility by utilizing crumb rubber from recycled tires. Both technologies contribute to sustainable pavement solutions by extending service life and improving resistance to deformation and cracking under various climatic and load conditions.

What is Polymer-Modified Asphalt?

Polymer-modified asphalt (PMA) incorporates synthetic polymers such as styrene-butadiene-styrene (SBS) to enhance the binder's elasticity, rutting resistance, and durability in paving applications. These polymers improve the asphalt's performance under extreme temperatures and heavy traffic loads, reducing cracks and deformation. PMA is widely used in highways and airport runways to extend pavement life and decrease maintenance costs compared to conventional asphalt.

What is Rubber-Modified Asphalt?

Rubber-modified asphalt incorporates crumb rubber derived from recycled tires to enhance pavement durability, flexibility, and resistance to cracking and rutting. This sustainable material improves pavement performance by increasing elasticity and vibration absorption, making it ideal for high-traffic roads. Studies show rubber-modified asphalt reduces road maintenance costs and extends the lifespan of highways compared to conventional asphalt mixes.

Key Material Differences

Polymer-modified asphalt (PMA) incorporates synthetic polymers like styrene-butadiene-styrene (SBS) to enhance elasticity, temperature susceptibility, and resistance to rutting and cracking. Rubber-modified asphalt (RMA) utilizes recycled crumb rubber from tires, improving flexibility, noise reduction, and durability under traffic loads. The primary material difference lies in PMA's use of synthetic polymers for performance enhancement, whereas RMA relies on tire-derived rubber for environmental benefits and improved pavement resilience.

Performance Comparison: Durability and Flexibility

Polymer-modified asphalt typically demonstrates enhanced durability and flexibility compared to rubber-modified asphalt, offering superior resistance to cracking and rutting under heavy traffic loads and extreme weather conditions. Rubber-modified asphalt provides excellent elasticity and shock absorption, making it particularly effective in reducing fatigue and thermal cracking, though it may require more maintenance over time. Performance outcomes vary based on specific polymer or rubber formulations, application methods, and environmental factors, influencing long-term pavement service life and maintenance costs.

Environmental Impact of Polymer vs Rubber Modification

Polymer-modified asphalt (PMA) primarily relies on synthetic polymers derived from petroleum, contributing to higher carbon emissions and non-renewable resource consumption during production. Rubber-modified asphalt (RMA), often produced using recycled tire rubber, significantly reduces landfill waste and lowers environmental impact by promoting material reuse. The sustainability benefits of RMA align with circular economy principles, offering a greener alternative with decreased ecological footprint compared to traditional polymer modifications.

Cost Analysis: Initial Investment and Lifecycle Costs

Polymer-modified asphalt typically demands a higher initial investment due to the cost of synthetic polymers but offers extended durability and reduced maintenance, lowering lifecycle costs over time. Rubber-modified asphalt involves a moderate initial cost with crumb rubber added from recycled tires, providing enhanced flexibility and resistance to cracking but may require more frequent maintenance in specific climates. Evaluating total expenditures, polymer-modified asphalt is often more cost-effective long-term due to its superior performance in high-stress environments, while rubber-modified choices can balance upfront costs and sustainability benefits.

Application Areas and Suitability

Polymer-modified asphalt (PMA) is commonly used in high-traffic urban roads, airport runways, and heavy-duty pavements due to its enhanced resistance to rutting and fatigue cracking. Rubber-modified asphalt (RMA) excels in flexible pavements and overlay projects, particularly on highways and streets requiring improved noise reduction and crack resistance. Both materials enhance pavement durability, but PMA is preferred for structural performance while RMA is favored for sustainability and flexibility in various climates.

Maintenance Requirements and Longevity

Polymer-modified asphalt exhibits enhanced durability and resistance to cracking, reducing maintenance frequency and extending pavement lifespan compared to conventional asphalt. Rubber-modified asphalt offers superior flexibility and elasticity, improving resistance to deformation and thermal stress, which lowers repair costs and enhances service life. Both materials contribute to longer-lasting pavements, but polymer-modified asphalt typically requires less frequent maintenance due to its improved structural properties.

Future Trends in Asphalt Modification

Polymer-modified asphalt (PMA) continues to dominate future trends due to its enhanced performance in temperature susceptibility and fatigue resistance, offering longer-lasting pavement solutions. Rubber-modified asphalt (RMA) gains traction as sustainability concerns drive demand for recycled materials, improving elasticity and crack resistance. Emerging hybrid technologies combining polymers and rubber additives promise optimized durability and environmental benefits, shaping the next generation of road construction materials.

Polymer-Modified Asphalt vs Rubber-Modified Asphalt Infographic

materialdif.com

materialdif.com