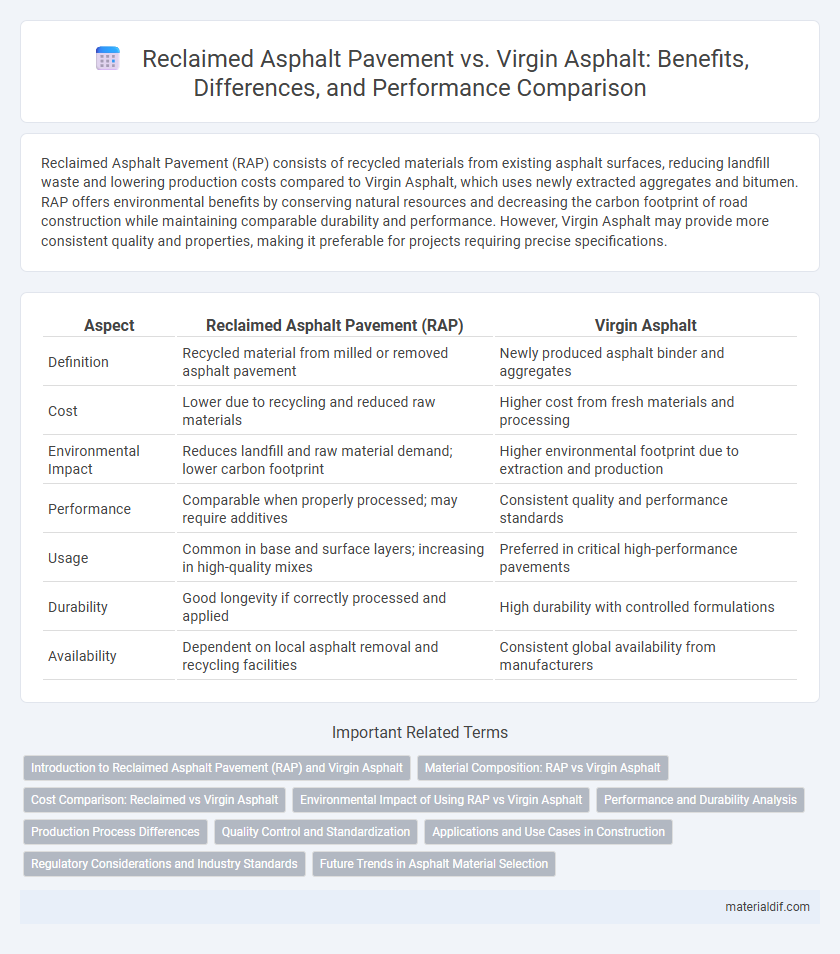

Reclaimed Asphalt Pavement (RAP) consists of recycled materials from existing asphalt surfaces, reducing landfill waste and lowering production costs compared to Virgin Asphalt, which uses newly extracted aggregates and bitumen. RAP offers environmental benefits by conserving natural resources and decreasing the carbon footprint of road construction while maintaining comparable durability and performance. However, Virgin Asphalt may provide more consistent quality and properties, making it preferable for projects requiring precise specifications.

Table of Comparison

| Aspect | Reclaimed Asphalt Pavement (RAP) | Virgin Asphalt |

|---|---|---|

| Definition | Recycled material from milled or removed asphalt pavement | Newly produced asphalt binder and aggregates |

| Cost | Lower due to recycling and reduced raw materials | Higher cost from fresh materials and processing |

| Environmental Impact | Reduces landfill and raw material demand; lower carbon footprint | Higher environmental footprint due to extraction and production |

| Performance | Comparable when properly processed; may require additives | Consistent quality and performance standards |

| Usage | Common in base and surface layers; increasing in high-quality mixes | Preferred in critical high-performance pavements |

| Durability | Good longevity if correctly processed and applied | High durability with controlled formulations |

| Availability | Dependent on local asphalt removal and recycling facilities | Consistent global availability from manufacturers |

Introduction to Reclaimed Asphalt Pavement (RAP) and Virgin Asphalt

Reclaimed Asphalt Pavement (RAP) consists of milled or removed asphalt materials from existing pavement surfaces, which are processed and reused in new asphalt mixtures to enhance sustainability and reduce costs. Virgin asphalt is produced from unaltered petroleum compounds, offering consistent quality and performance but at higher environmental and financial costs. Integrating RAP in asphalt production decreases natural resource consumption and lowers greenhouse gas emissions while maintaining pavement durability and strength.

Material Composition: RAP vs Virgin Asphalt

Reclaimed Asphalt Pavement (RAP) consists of milled asphalt material reclaimed from old pavements, containing aged binder and aggregates, whereas virgin asphalt uses new, untreated bitumen combined with fresh aggregates. RAP incorporates a high percentage of recycled binder, which often requires modification to restore flexibility and performance comparable to virgin mixes. Material composition differences impact durability, with RAP offering environmental benefits by reducing the demand for new asphalt binder and aggregates while maintaining structural integrity when properly processed.

Cost Comparison: Reclaimed vs Virgin Asphalt

Reclaimed Asphalt Pavement (RAP) significantly reduces costs compared to virgin asphalt by lowering material expenses, with savings reaching up to 50% in some projects. The recycling process requires less energy and fewer raw materials, reducing production and transportation costs. Virgin asphalt involves purchasing entirely new materials, which drives up expenses due to oil price fluctuations and higher extraction costs.

Environmental Impact of Using RAP vs Virgin Asphalt

Using Reclaimed Asphalt Pavement (RAP) significantly reduces the demand for virgin asphalt binder, lowering greenhouse gas emissions by up to 75% compared to producing new asphalt. RAP conserves natural resources by recycling existing materials, decreasing energy consumption and limiting landfill waste. Studies show that incorporating RAP can reduce carbon footprint and resource depletion, contributing to sustainable pavement construction practices.

Performance and Durability Analysis

Reclaimed Asphalt Pavement (RAP) demonstrates comparable performance and enhanced sustainability in comparison to Virgin Asphalt, with studies showing that RAP mixtures maintain adequate stiffness and resistance to deformation under high traffic loads. RAP's aged binder contributes to increased rutting resistance but may require rejuvenators to restore flexibility and prevent cracking over time. Durability analyses reveal that properly processed RAP can extend pavement life cycles while reducing environmental impact and production costs.

Production Process Differences

Reclaimed Asphalt Pavement (RAP) involves milling and crushing existing asphalt materials, allowing for the reuse of aged binder and aggregates, reducing the need for new raw materials. Virgin asphalt production requires extracting and refining bitumen from crude oil, followed by mixing with virgin aggregates, representing a more energy-intensive process. RAP significantly lowers greenhouse gas emissions and energy consumption by minimizing extraction and processing compared to virgin asphalt manufacturing.

Quality Control and Standardization

Reclaimed Asphalt Pavement (RAP) quality control involves rigorous screening and testing to ensure consistency in particle size and binder content, meeting standard specifications such as those outlined by ASTM and AASHTO. Virgin asphalt benefits from controlled production environments yielding uniform binder properties and aggregate gradation, facilitating easier standardization and predictable performance in mix designs. Implementing standardized protocols for RAP inclusion is critical to maintaining pavement durability and performance comparable to virgin asphalt mixtures.

Applications and Use Cases in Construction

Reclaimed Asphalt Pavement (RAP) is extensively used in road base and surface layers for sustainable highway construction, offering cost-effective and environmentally friendly alternatives to Virgin Asphalt. Virgin Asphalt, characterized by its high binder quality and consistency, is preferred for high-strength applications such as airport runways and heavy-traffic urban roads where durability and performance are critical. Combining RAP with Virgin Asphalt enhances mix design flexibility, allowing customized applications in residential streets, parking lots, and rehabilitation projects.

Regulatory Considerations and Industry Standards

Reclaimed Asphalt Pavement (RAP) must comply with stringent regulatory considerations such as limits on allowable recycled content and performance criteria defined by agencies like the Federal Highway Administration (FHWA) and the Environmental Protection Agency (EPA). Industry standards, including those set by ASTM and the Asphalt Institute, dictate testing protocols for RAP quality to ensure it meets durability and safety requirements comparable to virgin asphalt. Incorporating RAP can reduce environmental impact and costs but requires adherence to regulatory frameworks and acceptance criteria to guarantee pavement longevity and performance.

Future Trends in Asphalt Material Selection

Reclaimed Asphalt Pavement (RAP) is increasingly favored over virgin asphalt due to sustainability goals, cost efficiency, and advances in recycling technologies that maintain pavement performance. Future trends indicate a rise in high-quality RAP incorporation and the use of warm mix asphalt techniques to reduce energy consumption and emissions. Innovations in binder modification and quality control testing further enhance RAP's viability as the preferred material in asphalt pavement construction.

Reclaimed Asphalt Pavement vs Virgin Asphalt Infographic

materialdif.com

materialdif.com