Slurry seal and microsurfacing are both effective asphalt maintenance techniques designed to extend pavement life by sealing cracks and restoring surface texture. Slurry seal uses a slower-curing emulsion suitable for lighter traffic and smaller cracks, while microsurfacing employs a polymer-modified emulsion that cures faster and supports heavier traffic and more extensive repairs. Choosing between slurry seal and microsurfacing depends on the pavement condition, traffic load, and desired turnaround time for the project.

Table of Comparison

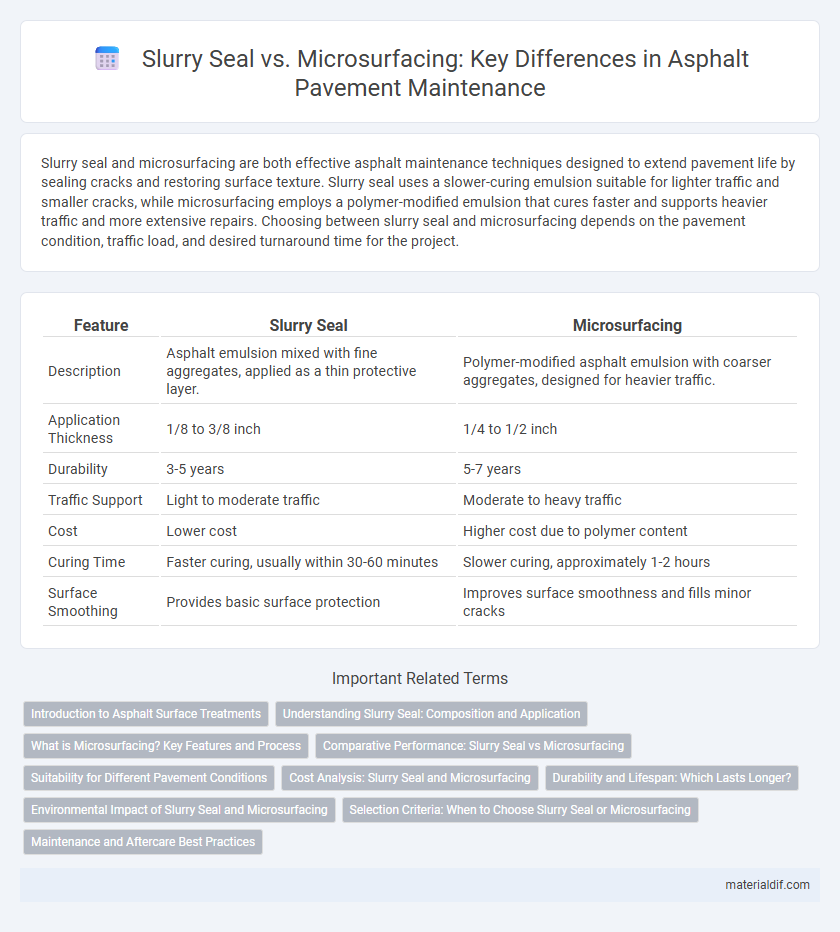

| Feature | Slurry Seal | Microsurfacing |

|---|---|---|

| Description | Asphalt emulsion mixed with fine aggregates, applied as a thin protective layer. | Polymer-modified asphalt emulsion with coarser aggregates, designed for heavier traffic. |

| Application Thickness | 1/8 to 3/8 inch | 1/4 to 1/2 inch |

| Durability | 3-5 years | 5-7 years |

| Traffic Support | Light to moderate traffic | Moderate to heavy traffic |

| Cost | Lower cost | Higher cost due to polymer content |

| Curing Time | Faster curing, usually within 30-60 minutes | Slower curing, approximately 1-2 hours |

| Surface Smoothing | Provides basic surface protection | Improves surface smoothness and fills minor cracks |

Introduction to Asphalt Surface Treatments

Slurry seal and microsurfacing are common asphalt surface treatments designed to extend pavement life and improve driving conditions. Slurry seal uses a mixture of water, asphalt emulsion, aggregate, and additives, creating a thin protective layer ideal for minor pavement repairs. Microsurfacing incorporates polymer-modified asphalt emulsions allowing quicker curing times and enhanced durability, suitable for more extensive pavement maintenance and traffic loads.

Understanding Slurry Seal: Composition and Application

Slurry seal consists of a mixture of asphalt emulsion, fine aggregates, water, and additives designed for thin surface treatments on asphalt pavements. It is applied using specialized equipment that spreads a uniform layer, providing a protective seal that enhances surface texture and extends pavement life. This cost-effective method is ideal for maintenance on roads with minimal cracking but is less durable than microsurfacing for heavier traffic conditions.

What is Microsurfacing? Key Features and Process

Microsurfacing is a pavement maintenance technique that uses a specialized mixture of polymer-modified asphalt emulsion, aggregate, water, and mineral fillers to create a durable, flexible surface layer. Key features include rapid curing time, weather resistance, and the ability to fill surface irregularities while providing skid resistance and waterproofing. The process involves uniformly applying the mixture with specialized equipment, allowing roads to reopen quickly and extending pavement life efficiently.

Comparative Performance: Slurry Seal vs Microsurfacing

Slurry seal provides a thinner, more flexible protective layer ideal for minor pavement repairs and is less costly compared to microsurfacing, which offers a thicker, stronger surface capable of addressing moderate rutting and surface distress. Microsurfacing cures faster and supports heavier traffic loads due to higher polymer content and aggregate quality, making it more durable in long-term performance. Both treatments improve skid resistance and extend pavement life, but microsurfacing typically delivers superior results in structural enhancement and water resistance.

Suitability for Different Pavement Conditions

Slurry seal is best suited for light to moderate traffic roads with relatively stable pavement conditions, effectively sealing surface cracks and preventing water infiltration. Microsurfacing is ideal for higher traffic volumes and more distressed pavements, providing faster curing times and improved rut resistance. Selecting between slurry seal and microsurfacing depends on the specific pavement distress, traffic load, and desired longevity.

Cost Analysis: Slurry Seal and Microsurfacing

Slurry seal typically costs between $1.00 and $2.50 per square yard, making it a more budget-friendly option for surface maintenance and minor repairs on asphalt pavements. Microsurfacing ranges from $2.00 to $4.00 per square yard but offers enhanced durability and faster curing times, justifying the higher investment for areas with heavy traffic. Cost efficiency depends on project scale, desired longevity, and performance requirements, with slurry seal favored for cost-sensitive projects and microsurfacing preferred for long-term pavement preservation.

Durability and Lifespan: Which Lasts Longer?

Slurry seal typically lasts 3 to 5 years, providing a cost-effective surface treatment for low to moderate traffic roads, while microsurfacing offers enhanced durability with a lifespan of 5 to 7 years due to advanced polymer-modified asphalt emulsions. Microsurfacing is better suited for high-traffic areas and can withstand heavier loads and harsher weather conditions, making it a more long-lasting solution for pavement maintenance. The choice between slurry seal and microsurfacing depends on traffic volume, pavement condition, and desired lifespan, with microsurfacing generally offering superior longevity.

Environmental Impact of Slurry Seal and Microsurfacing

Slurry seal uses lower VOC content emulsions, reducing harmful air pollutants, while microsurfacing often incorporates polymer-modified emulsions that may emit slightly higher VOCs but provide longer-lasting pavement protection. Both treatments utilize recycled aggregates, promoting sustainable resource use and minimizing landfill waste. Microsurfacing typically has a faster curing time, leading to reduced traffic disruptions and lower vehicle emissions during maintenance operations.

Selection Criteria: When to Choose Slurry Seal or Microsurfacing

Slurry seal is ideal for low-traffic roads with minor surface distress, providing a cost-effective, thin protective layer to extend pavement life. Microsurfacing suits high-traffic areas with moderate distress, offering faster curing times and greater durability due to polymer-modified binders. Selecting between slurry seal and microsurfacing depends on traffic volume, pavement condition, and desired longevity of the treatment.

Maintenance and Aftercare Best Practices

Slurry seal and microsurfacing each require specific maintenance and aftercare to ensure long-lasting pavement protection, with slurry seal needing light maintenance like regular cleaning to avoid debris buildup and faster drying times allowing quicker reopening to traffic. Microsurfacing demands careful curing time management and periodic inspections to address potential micro-cracking or wear due to its thicker, more durable application designed for heavier traffic areas. Applying routine sealcoating and timely crack sealing extends the lifespan of both treatments, while ensuring proper drainage prevents water damage and preserves surface integrity.

Slurry Seal vs Microsurfacing Infographic

materialdif.com

materialdif.com