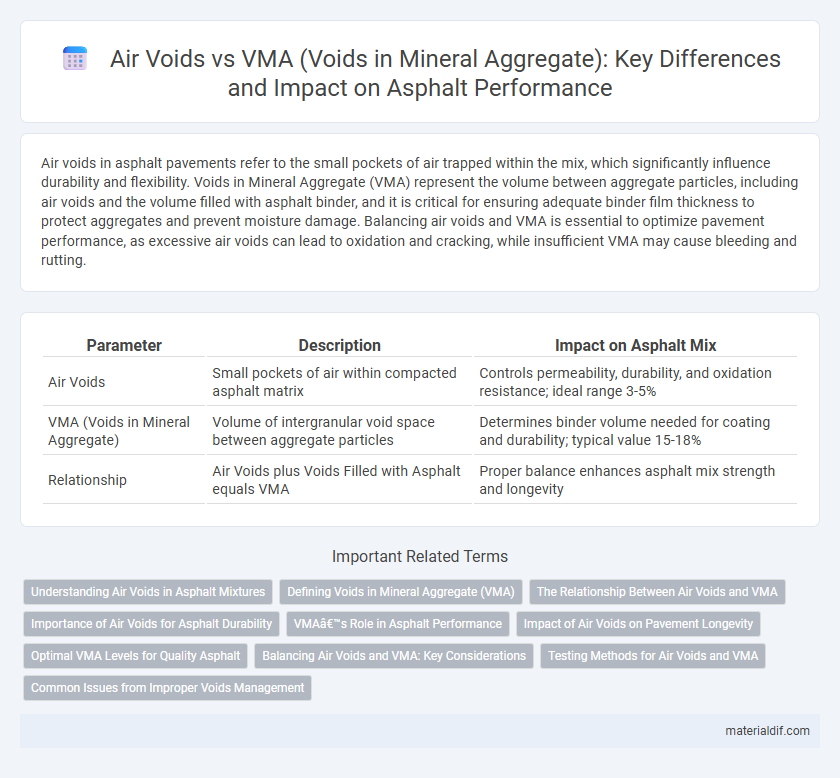

Air voids in asphalt pavements refer to the small pockets of air trapped within the mix, which significantly influence durability and flexibility. Voids in Mineral Aggregate (VMA) represent the volume between aggregate particles, including air voids and the volume filled with asphalt binder, and it is critical for ensuring adequate binder film thickness to protect aggregates and prevent moisture damage. Balancing air voids and VMA is essential to optimize pavement performance, as excessive air voids can lead to oxidation and cracking, while insufficient VMA may cause bleeding and rutting.

Table of Comparison

| Parameter | Description | Impact on Asphalt Mix |

|---|---|---|

| Air Voids | Small pockets of air within compacted asphalt matrix | Controls permeability, durability, and oxidation resistance; ideal range 3-5% |

| VMA (Voids in Mineral Aggregate) | Volume of intergranular void space between aggregate particles | Determines binder volume needed for coating and durability; typical value 15-18% |

| Relationship | Air Voids plus Voids Filled with Asphalt equals VMA | Proper balance enhances asphalt mix strength and longevity |

Understanding Air Voids in Asphalt Mixtures

Air voids in asphalt mixtures are the small pockets of air trapped between coated aggregate particles, typically ranging from 3% to 6% to ensure durability and flexibility. VMA (Voids in Mineral Aggregate) represents the volume between aggregate particles including air voids and asphalt binder, crucial for accommodating enough binder to coat aggregates and maintain pavement performance. A proper balance between air voids and VMA is essential to prevent premature pavement distress like rutting or cracking by optimizing mixture density and binder content.

Defining Voids in Mineral Aggregate (VMA)

Voids in Mineral Aggregate (VMA) represent the total volume of intergranular void spaces between the aggregate particles in an asphalt mixture, including both air voids and the volume occupied by asphalt binder not absorbed by the aggregate. VMA is a critical parameter in asphalt mix design as it directly influences durability, stability, and resistance to deformation by controlling the binder content and its distribution within the mixture. Proper VMA ensures adequate binder film thickness around aggregates, enhancing pavement performance and longevity.

The Relationship Between Air Voids and VMA

Air voids and VMA (Voids in Mineral Aggregate) are critical parameters in asphalt mix design that directly influence pavement durability and performance. VMA represents the total volume of intergranular void space between aggregate particles, while air voids refer to the portion of this space not filled with asphalt binder. A balanced relationship between air voids and VMA ensures adequate binder film thickness for aggregate coating and prevents excessive permeability, thus optimizing resistance to cracking and rutting.

Importance of Air Voids for Asphalt Durability

Air voids in asphalt significantly influence its durability by controlling permeability and resistance to moisture damage, preventing premature pavement deterioration. Proper air void content balances flexibility and strength, enhancing load-bearing capacity while minimizing oxidation and aging. Maintaining optimal air voids ensures long-term performance and reduces the risk of cracks, rutting, and potholes in asphalt pavements.

VMA’s Role in Asphalt Performance

VMA (Voids in Mineral Aggregate) plays a critical role in asphalt performance by ensuring there is adequate space to accommodate binder and air voids, which directly impacts durability and resistance to deformation. Optimal VMA levels enhance the asphalt mix's ability to resist rutting and cracking by providing sufficient binder film thickness for aggregate particles. Maintaining proper air voids within the VMA range improves permeability and prevents premature pavement failures caused by moisture damage or oxidation.

Impact of Air Voids on Pavement Longevity

Air voids in asphalt mixtures significantly influence pavement durability by controlling permeability and resistance to deformation, with optimal air void content typically ranging between 3% and 5% to balance durability and flexibility. VMA (Voids in Mineral Aggregate) affects the asphalt binder film thickness, essential for protecting aggregate particles and accommodating traffic loads. Excessive air voids reduce pavement longevity by allowing moisture infiltration and oxidative aging, whereas insufficient air voids can lead to rutting and fatigue failures due to inadequate compaction and binder film insufficiency.

Optimal VMA Levels for Quality Asphalt

Optimal VMA levels in asphalt mixtures typically range between 13% and 18% to achieve durable pavement with sufficient air voids. Maintaining air voids around 3% to 5% is crucial for preventing premature pavement distress such as rutting and cracking. Proper balance between air voids and VMA ensures adequate binder film thickness and compactability, enhancing long-term performance and skid resistance.

Balancing Air Voids and VMA: Key Considerations

Balancing air voids and VMA in asphalt mix design is crucial to achieving durability and performance. Optimal air voids, typically ranging from 3% to 5%, ensure adequate compaction and prevent pavement distresses like rutting and cracking. Maintaining sufficient VMA, usually between 15% and 18%, allows enough space for asphalt binder to coat aggregate particles, enhancing mixture stability and longevity.

Testing Methods for Air Voids and VMA

Air voids and Voids in Mineral Aggregate (VMA) are critical parameters in asphalt mix design, influencing durability and performance. Testing methods for air voids typically involve core sampling and bulk specific gravity measurements using ASTM D6752 or AASHTO T166 standards to determine the volume of air pockets within compacted asphalt samples. VMA is calculated from the aggregate and asphalt binder volume by subtracting the volume of the aggregate particles from the total volume; this requires precise aggregate and mix volumetric analysis often performed via ASTM D2726 or AASHTO T209 for bulk specific gravity of the uncompacted mix.

Common Issues from Improper Voids Management

Improper management of air voids and VMA in asphalt mixtures can lead to common issues such as reduced durability, increased susceptibility to moisture damage, and premature pavement cracking. Insufficient air voids often cause bleeding and rutting, while excessive air voids result in permeability and binder oxidation. Balancing air voids and VMA is critical to optimizing pavement performance and longevity.

Air Voids vs VMA (Voids in Mineral Aggregate) Infographic

materialdif.com

materialdif.com