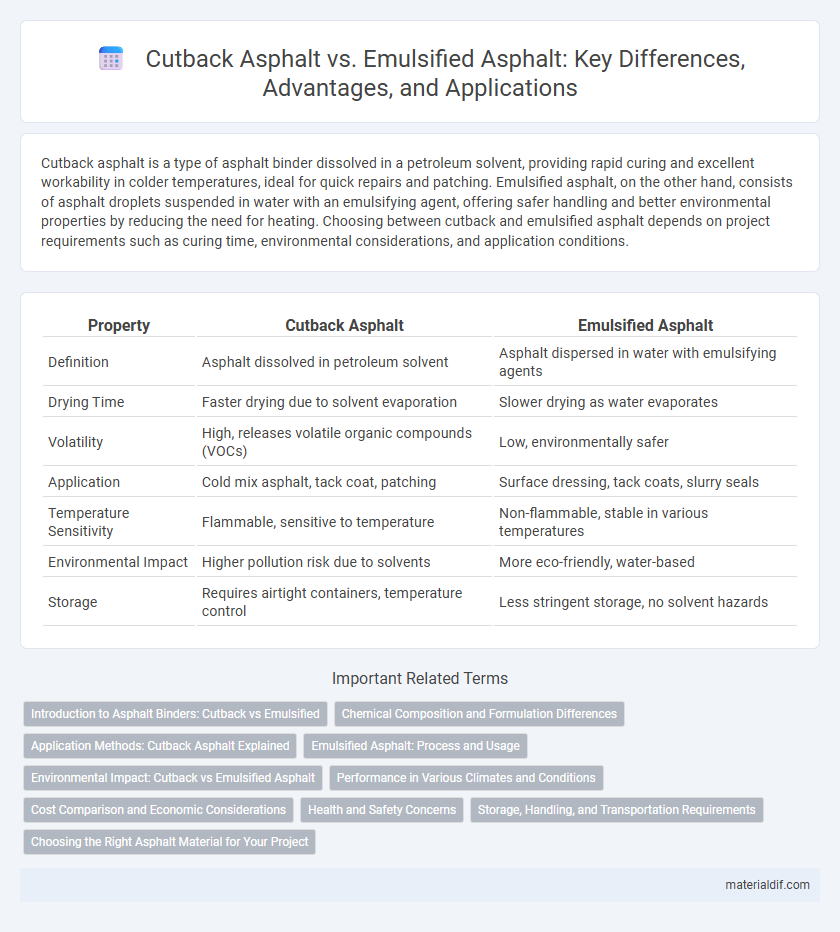

Cutback asphalt is a type of asphalt binder dissolved in a petroleum solvent, providing rapid curing and excellent workability in colder temperatures, ideal for quick repairs and patching. Emulsified asphalt, on the other hand, consists of asphalt droplets suspended in water with an emulsifying agent, offering safer handling and better environmental properties by reducing the need for heating. Choosing between cutback and emulsified asphalt depends on project requirements such as curing time, environmental considerations, and application conditions.

Table of Comparison

| Property | Cutback Asphalt | Emulsified Asphalt |

|---|---|---|

| Definition | Asphalt dissolved in petroleum solvent | Asphalt dispersed in water with emulsifying agents |

| Drying Time | Faster drying due to solvent evaporation | Slower drying as water evaporates |

| Volatility | High, releases volatile organic compounds (VOCs) | Low, environmentally safer |

| Application | Cold mix asphalt, tack coat, patching | Surface dressing, tack coats, slurry seals |

| Temperature Sensitivity | Flammable, sensitive to temperature | Non-flammable, stable in various temperatures |

| Environmental Impact | Higher pollution risk due to solvents | More eco-friendly, water-based |

| Storage | Requires airtight containers, temperature control | Less stringent storage, no solvent hazards |

Introduction to Asphalt Binders: Cutback vs Emulsified

Cutback asphalt is a binder produced by dissolving asphalt cement in petroleum solvents such as kerosene or diesel to achieve desired fluidity for easier application in paving and maintenance. Emulsified asphalt consists of asphalt cement finely dispersed in water with the help of emulsifying agents, allowing it to be applied at lower temperatures while improving adhesion and environmental safety. Understanding the differences in composition, drying mechanisms, and application methods between cutback and emulsified asphalt is essential for selecting the appropriate binder in road construction and repair projects.

Chemical Composition and Formulation Differences

Cutback asphalt consists of asphalt cement dissolved in petroleum solvents like naphtha or kerosene, which evaporate after application to leave a tacky binder. Emulsified asphalt is a mixture of asphalt cement, water, and an emulsifying agent such as soaps or synthetic polymers, forming fine droplets suspended in water that break and set upon contact with aggregate. The chemical formulation of cutback asphalt prioritizes solvent evaporation for curing, while emulsified asphalt relies on the destabilization of the emulsion to achieve adhesion and strength.

Application Methods: Cutback Asphalt Explained

Cutback asphalt is applied by dissolving asphalt cement in a petroleum solvent, allowing it to penetrate surfaces easily before the solvent evaporates, making it ideal for cold weather applications and quick curing. Its application method involves spraying or mixing the solution directly onto pavements or aggregates. Compared to emulsified asphalt, cutback asphalt offers faster drying times but poses environmental concerns due to solvent emissions.

Emulsified Asphalt: Process and Usage

Emulsified asphalt is produced by mixing asphalt cement with water and an emulsifying agent, creating a stable suspension of tiny asphalt droplets in water that facilitates easier transportation and application at lower temperatures. This type of asphalt is widely used for surface treatments, tack coats, and cold mix applications, offering environmental advantages through reduced emissions and energy consumption. Its rapid setting characteristics and strong adhesion make it ideal for road maintenance, crack sealing, and dust control on unpaved surfaces.

Environmental Impact: Cutback vs Emulsified Asphalt

Cutback asphalt releases volatile organic compounds (VOCs) during application, contributing to air pollution and posing health risks. Emulsified asphalt uses water as a carrier, significantly reducing VOC emissions and minimizing environmental hazards. Lower toxicity and improved biodegradability make emulsified asphalt a more eco-friendly choice for pavement and road construction projects.

Performance in Various Climates and Conditions

Cutback asphalt offers superior performance in cold conditions due to its slower curing time and ability to remain pliable, making it ideal for low-temperature environments. Emulsified asphalt performs better in moderate to warm climates, as its water-based composition allows for quicker curing and reduced environmental impact. Both types show distinct advantages depending on climate, with cutback preferred for freeze-thaw cycles and emulsified favored in hot, dry conditions.

Cost Comparison and Economic Considerations

Cutback asphalt typically incurs higher initial costs due to the use of petroleum solvents, but offers quicker drying times which can reduce labor expenses in road construction projects. Emulsified asphalt is more economical in terms of material cost and environmental impact, as it uses water instead of solvents, leading to safer handling and lower regulatory fees. Long-term economic considerations favor emulsified asphalt because of its reduced volatilization and better recyclability, which minimize maintenance and replacement costs over time.

Health and Safety Concerns

Cutback asphalt contains petroleum solvents that release volatile organic compounds (VOCs), posing inhalation hazards and increasing fire risk during handling and application. Emulsified asphalt, being water-based, significantly reduces toxic fume emissions and flammability, making it a safer choice for workers and the environment. Proper ventilation and protective equipment remain essential with both types to minimize exposure to potentially harmful chemicals.

Storage, Handling, and Transportation Requirements

Cutback asphalt requires storage in sealed, heated containers to maintain its liquid state and prevent evaporation of volatile solvents, demanding careful temperature control during handling and transportation. Emulsified asphalt, on the other hand, must be stored at ambient temperatures in agitation tanks to keep the emulsion stable, with transportation focusing on minimizing agitation to avoid breaking the emulsion. Proper equipment and adherence to temperature and agitation guidelines are critical for preserving the properties and performance of both cutback and emulsified asphalt during their storage, handling, and transportation phases.

Choosing the Right Asphalt Material for Your Project

Cutback asphalt, composed of bitumen dissolved in petroleum solvents, provides fast curing and strong adhesion, making it suitable for cold weather applications and quick repairs. Emulsified asphalt, a mixture of bitumen, water, and emulsifying agents, offers better environmental safety, slower curing time, and enhanced workability, ideal for road construction and surface treatments. Selecting the right material depends on project requirements such as climate conditions, curing time, environmental regulations, and application methods to ensure optimal performance and durability.

Cutback Asphalt vs Emulsified Asphalt Infographic

materialdif.com

materialdif.com