Batch plant asphalt offers precise control over mix quality by producing asphalt in discrete batches, allowing customization for specific project requirements. Drum plant asphalt provides continuous production with higher efficiency, ideal for large-scale road construction where consistent mix composition is acceptable. Selecting between batch and drum plants depends on factors like project size, quality control needs, and production speed.

Table of Comparison

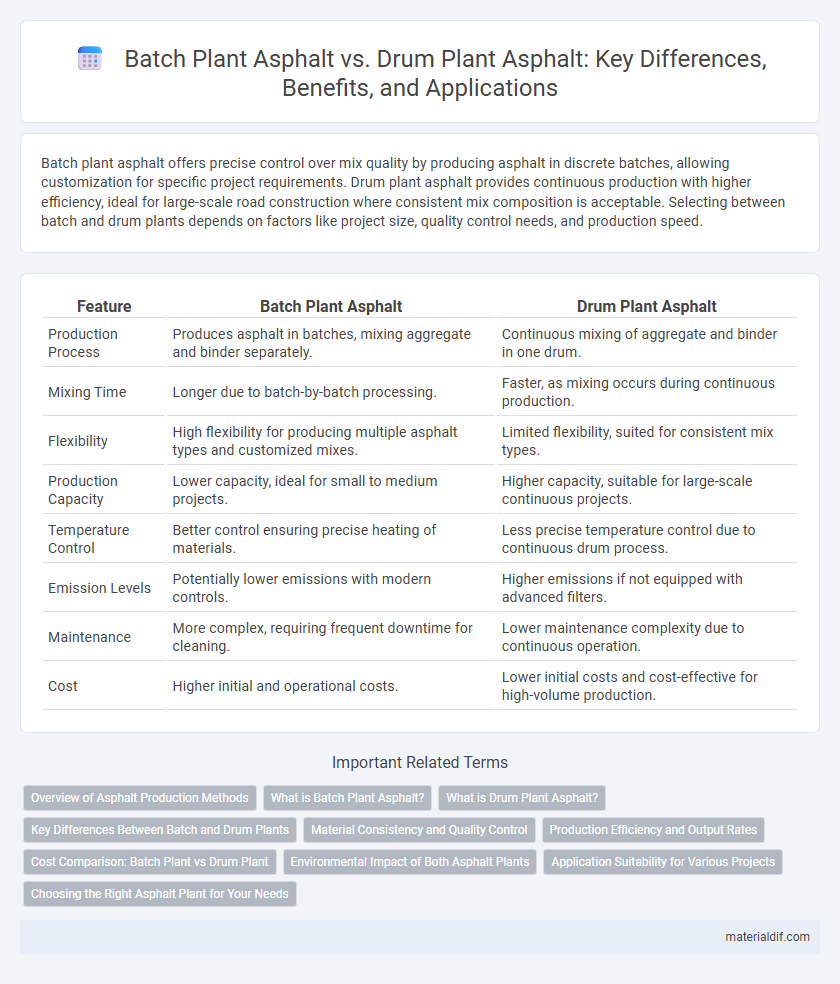

| Feature | Batch Plant Asphalt | Drum Plant Asphalt |

|---|---|---|

| Production Process | Produces asphalt in batches, mixing aggregate and binder separately. | Continuous mixing of aggregate and binder in one drum. |

| Mixing Time | Longer due to batch-by-batch processing. | Faster, as mixing occurs during continuous production. |

| Flexibility | High flexibility for producing multiple asphalt types and customized mixes. | Limited flexibility, suited for consistent mix types. |

| Production Capacity | Lower capacity, ideal for small to medium projects. | Higher capacity, suitable for large-scale continuous projects. |

| Temperature Control | Better control ensuring precise heating of materials. | Less precise temperature control due to continuous drum process. |

| Emission Levels | Potentially lower emissions with modern controls. | Higher emissions if not equipped with advanced filters. |

| Maintenance | More complex, requiring frequent downtime for cleaning. | Lower maintenance complexity due to continuous operation. |

| Cost | Higher initial and operational costs. | Lower initial costs and cost-effective for high-volume production. |

Overview of Asphalt Production Methods

Batch plant asphalt production involves mixing aggregates and bitumen in separate batches, allowing for precise control of mix composition and quality with flexibility for varying mix designs. Drum plant asphalt operates through a continuous process where aggregates are heated and coated with bitumen in a rotating drum, enabling higher production rates and efficiency. Each method offers distinct advantages depending on project requirements, production scale, and material specifications.

What is Batch Plant Asphalt?

Batch plant asphalt is produced by heating and drying aggregates before mixing them with liquid asphalt binder in discrete, measured batches. This process allows for precise control over the mix composition and consistency, making it ideal for projects requiring high-quality pavement materials. Batch plants typically handle smaller volumes compared to drum plants but offer greater flexibility in producing diverse asphalt mixtures.

What is Drum Plant Asphalt?

Drum plant asphalt is a continuous mixing process where aggregates and asphalt binder are combined in a revolving drum to produce hot mix asphalt efficiently. This method allows for steady production rates and is ideal for large-scale paving projects due to its consistent material quality and faster output. Unlike batch plants, drum plants provide seamless mixing without interruption, resulting in improved operational efficiency and reduced energy consumption.

Key Differences Between Batch and Drum Plants

Batch plant asphalt produces hot mix in discrete batches, allowing precise control over material proportions and facilitating high-quality, customized asphalt mixes. Drum plant asphalt operates continuously, blending aggregate and binder in a single drum, offering higher production rates and cost efficiency for large-scale projects. Key differences include production method, mix customization, and operational speed, influencing suitability based on project size and quality requirements.

Material Consistency and Quality Control

Batch plant asphalt offers superior material consistency and quality control due to its process of producing asphalt in discrete batches, allowing precise adjustments to mix proportions for each batch. Drum plant asphalt continuously mixes raw materials, which may result in less uniformity and limited real-time quality adjustments compared to batch plants. The ability of batch plants to closely monitor and adjust mix parameters ensures higher overall pavement performance and longevity.

Production Efficiency and Output Rates

Batch plant asphalt offers precise control over mix design and quality, producing asphalt in discrete batches ideal for varied specifications. Drum plant asphalt, designed for continuous production, excels in higher output rates and superior production efficiency, making it suitable for large-scale paving projects. Production efficiency in drum plants benefits from integrated drying and mixing, enabling faster throughput compared to the cyclical batch process.

Cost Comparison: Batch Plant vs Drum Plant

Batch plant asphalt typically incurs higher initial capital costs due to complex equipment and slower production rates but offers superior mix quality control, which can reduce long-term expenses. Drum plant asphalt features lower upfront investment and continuous production ideal for large projects, resulting in overall cost efficiency despite less precise mixing. Evaluating project scale and quality requirements is essential to determine the most cost-effective asphalt plant type.

Environmental Impact of Both Asphalt Plants

Batch plant asphalt produces higher emissions due to frequent heating cycles releasing volatile organic compounds (VOCs) and particulates, impacting air quality. Drum plant asphalt operates continuously with more efficient heating, resulting in lower fuel consumption and reduced greenhouse gas emissions. Both plants require dust control measures, but drum plants generally demonstrate a smaller environmental footprint through optimized energy use and reduced pollutant output.

Application Suitability for Various Projects

Batch plant asphalt offers precise mix control, making it ideal for projects requiring custom blends and frequent changes in asphalt composition, such as highway overlays and urban road repairs. Drum plant asphalt provides continuous production suited for large-scale, uniform projects like highways and airport runways where consistent asphalt quality and high output rates are essential. Choosing the right plant depends on project size, mix complexity, and the need for flexibility in asphalt formulation.

Choosing the Right Asphalt Plant for Your Needs

Batch plant asphalt offers precise control over mix quality by producing asphalt in separate batches, making it ideal for projects requiring frequent changes in mix specifications. Drum plant asphalt operates continuously, providing higher production rates and efficiency suited for large-scale paving projects with consistent material requirements. Selecting the right asphalt plant depends on project size, mix variability, and production speed, ensuring optimal cost-effectiveness and material performance.

Batch Plant Asphalt vs Drum Plant Asphalt Infographic

materialdif.com

materialdif.com