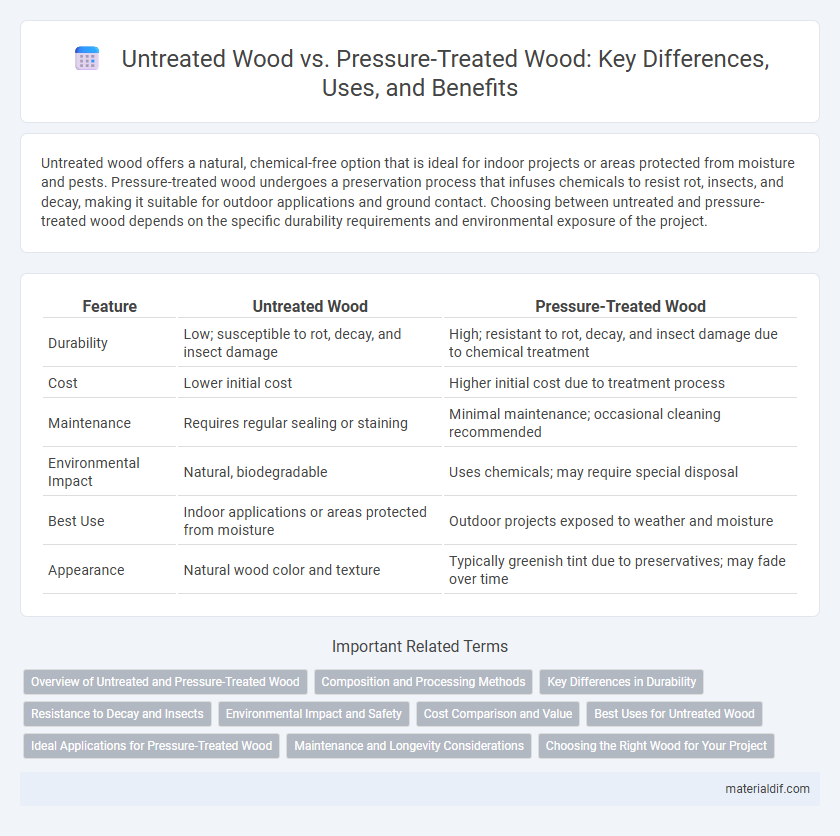

Untreated wood offers a natural, chemical-free option that is ideal for indoor projects or areas protected from moisture and pests. Pressure-treated wood undergoes a preservation process that infuses chemicals to resist rot, insects, and decay, making it suitable for outdoor applications and ground contact. Choosing between untreated and pressure-treated wood depends on the specific durability requirements and environmental exposure of the project.

Table of Comparison

| Feature | Untreated Wood | Pressure-Treated Wood |

|---|---|---|

| Durability | Low; susceptible to rot, decay, and insect damage | High; resistant to rot, decay, and insect damage due to chemical treatment |

| Cost | Lower initial cost | Higher initial cost due to treatment process |

| Maintenance | Requires regular sealing or staining | Minimal maintenance; occasional cleaning recommended |

| Environmental Impact | Natural, biodegradable | Uses chemicals; may require special disposal |

| Best Use | Indoor applications or areas protected from moisture | Outdoor projects exposed to weather and moisture |

| Appearance | Natural wood color and texture | Typically greenish tint due to preservatives; may fade over time |

Overview of Untreated and Pressure-Treated Wood

Untreated wood is natural lumber that has not been chemically altered, making it prone to decay, insect damage, and weathering when exposed to outdoor elements. Pressure-treated wood undergoes a process where preservatives are forced deep into the wood fibers under high pressure, enhancing resistance to moisture, rot, and pests, making it ideal for outdoor projects such as decks and fences. Comparing the two, untreated wood is typically used for indoor applications or sheltered environments, whereas pressure-treated wood offers greater durability and longevity in exterior settings.

Composition and Processing Methods

Untreated wood consists of natural timber without chemical additives, preserving its original cellular structure but making it more susceptible to moisture, decay, and insect damage. Pressure-treated wood undergoes a high-pressure process where preservatives such as copper-based compounds are infused deeply into the wood fibers, significantly enhancing resistance to rot, fungi, and pests. The chemical treatment alters the wood's composition by embedding biocides and stabilizers, which extend its durability for outdoor and structural applications.

Key Differences in Durability

Untreated wood is more susceptible to rot, insect damage, and weathering due to its natural composition and lack of protective chemicals. Pressure-treated wood undergoes a chemical infusion process that significantly enhances its resistance to moisture, fungi, and termites, extending its lifespan in outdoor or high-humidity environments. The durability of pressure-treated wood makes it suitable for structural applications such as decks, fences, and outdoor furniture, whereas untreated wood is better suited for indoor or dry conditions.

Resistance to Decay and Insects

Untreated wood is highly susceptible to decay and insect damage, especially in moist or outdoor environments, due to the lack of protective chemicals. Pressure-treated wood undergoes a preservation process where chemical preservatives penetrate deeply, significantly enhancing resistance to rot, fungi, termites, and other wood-boring insects. This makes pressure-treated wood a preferred choice for outdoor structures such as decks, fences, and landscaping components exposed to harsh environmental conditions.

Environmental Impact and Safety

Untreated wood is free from chemicals, reducing environmental pollution and making it safer for indoor use and direct contact with humans and pets. Pressure-treated wood undergoes chemical treatments, such as chromated copper arsenate (CCA) or alkaline copper quaternary (ACQ), which enhance durability but may leach harmful substances into soil and water, raising environmental and health concerns. Choosing untreated wood supports sustainability and indoor air quality, while pressure-treated wood offers longevity at the potential cost of environmental toxicity.

Cost Comparison and Value

Untreated wood generally costs less upfront, making it a budget-friendly option for short-term projects or indoor use. Pressure-treated wood commands a higher initial price due to chemical preservatives that enhance durability and resistance to rot, insects, and weathering. Over time, pressure-treated wood provides better value by minimizing maintenance costs and extending the lifespan of structures in outdoor or high-moisture environments.

Best Uses for Untreated Wood

Untreated wood is ideal for indoor applications such as furniture, cabinetry, and decorative trim where exposure to moisture and insects is minimal. It retains its natural appearance and is easier to machine and finish compared to pressure-treated wood. Best suited for controlled environments, untreated wood offers cost-effective solutions for projects emphasizing aesthetic quality and indoor durability.

Ideal Applications for Pressure-Treated Wood

Pressure-treated wood is ideal for outdoor applications requiring enhanced durability and resistance to moisture, insects, and decay. It is commonly used for decks, fences, garden beds, and other structures exposed to harsh weather conditions or direct ground contact. The chemical treatment extends the wood's lifespan, making it suitable for areas with high humidity or frequent exposure to water.

Maintenance and Longevity Considerations

Untreated wood requires regular sealing and staining to prevent moisture damage, rot, and insect infestation, significantly increasing maintenance efforts over time. Pressure-treated wood is infused with chemical preservatives that enhance resistance to decay and pests, reducing the need for frequent upkeep and extending the wood's lifespan by decades. Selecting pressure-treated wood is ideal for outdoor projects exposed to moisture, ensuring long-term durability with minimal maintenance.

Choosing the Right Wood for Your Project

Untreated wood offers natural aesthetics and is ideal for indoor projects or areas with minimal exposure to moisture, while pressure-treated wood is chemically infused to resist rot, insects, and decay, making it suitable for outdoor structures like decks and fences. Choosing the right wood depends on environmental exposure, durability requirements, and maintenance preferences; untreated wood requires sealing for protection, whereas pressure-treated wood demands periodic inspection for treatment efficacy. Considering factors such as climate, project lifespan, and intended use ensures optimal material performance and longevity.

Untreated Wood vs Pressure-Treated Wood Infographic

materialdif.com

materialdif.com