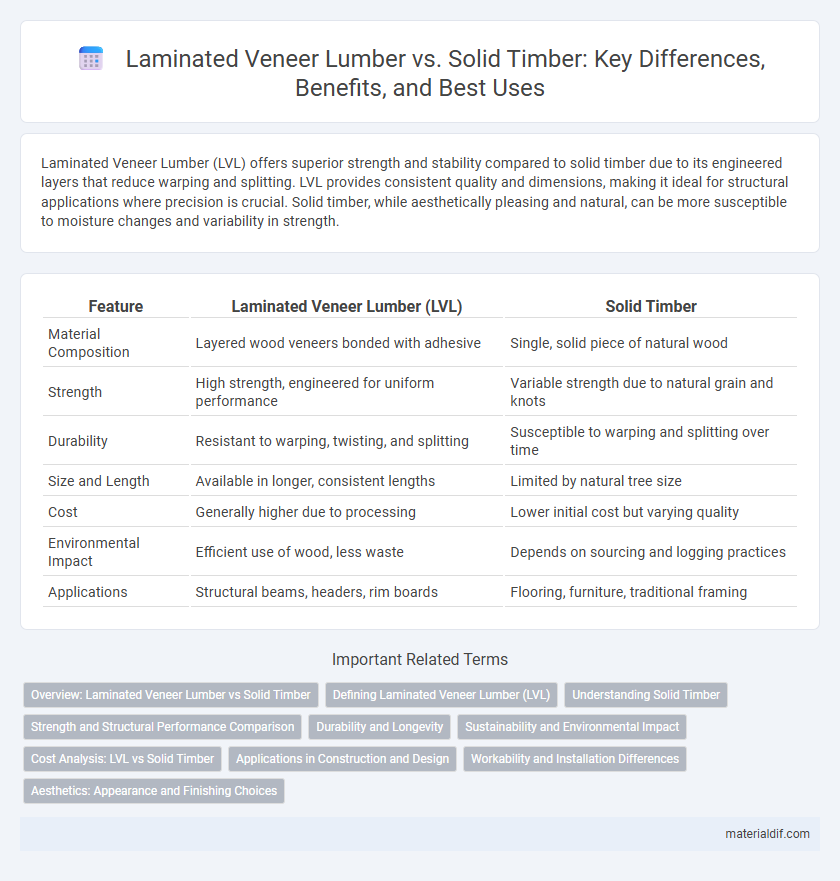

Laminated Veneer Lumber (LVL) offers superior strength and stability compared to solid timber due to its engineered layers that reduce warping and splitting. LVL provides consistent quality and dimensions, making it ideal for structural applications where precision is crucial. Solid timber, while aesthetically pleasing and natural, can be more susceptible to moisture changes and variability in strength.

Table of Comparison

| Feature | Laminated Veneer Lumber (LVL) | Solid Timber |

|---|---|---|

| Material Composition | Layered wood veneers bonded with adhesive | Single, solid piece of natural wood |

| Strength | High strength, engineered for uniform performance | Variable strength due to natural grain and knots |

| Durability | Resistant to warping, twisting, and splitting | Susceptible to warping and splitting over time |

| Size and Length | Available in longer, consistent lengths | Limited by natural tree size |

| Cost | Generally higher due to processing | Lower initial cost but varying quality |

| Environmental Impact | Efficient use of wood, less waste | Depends on sourcing and logging practices |

| Applications | Structural beams, headers, rim boards | Flooring, furniture, traditional framing |

Overview: Laminated Veneer Lumber vs Solid Timber

Laminated Veneer Lumber (LVL) is engineered by bonding thin wood veneers with adhesives, resulting in a product with consistent strength and stability, ideal for structural applications such as beams and headers. Solid timber, derived directly from logs, offers natural aesthetics and grain patterns but may exhibit variability in strength and susceptibility to warping or splitting. LVL outperforms solid timber in uniformity and dimensional stability, making it a preferred choice for precise and load-bearing construction tasks.

Defining Laminated Veneer Lumber (LVL)

Laminated Veneer Lumber (LVL) is an engineered wood product made by bonding thin wood veneers together under heat and pressure, creating a strong, uniform material ideal for structural applications. Unlike solid timber, LVL offers enhanced dimensional stability, consistent strength, and resistance to warping, making it suitable for beams, headers, and columns in construction. Its engineered composition allows for longer spans and greater load-bearing capacity compared to traditional solid wood.

Understanding Solid Timber

Solid timber, sourced directly from natural logs, offers inherent strength and durability due to its continuous grain structure, making it ideal for load-bearing applications and traditional woodworking. Unlike laminated veneer lumber (LVL), which is engineered by bonding multiple veneers for uniformity and dimensional stability, solid timber provides unique aesthetic appeal with natural variations and character. Its susceptibility to moisture-induced warping and shrinkage requires careful seasoning and maintenance to ensure long-term performance in construction and furniture making.

Strength and Structural Performance Comparison

Laminated Veneer Lumber (LVL) offers superior strength and structural reliability compared to solid timber due to its engineered composition of multiple wood veneers bonded under heat and pressure. LVL exhibits higher load-bearing capacity, reduced warping, and consistent dimensional stability, making it ideal for long spans in construction. Solid timber, while aesthetically natural, often contains knots and grain irregularities that can weaken its structural performance under heavy loads.

Durability and Longevity

Laminated Veneer Lumber (LVL) demonstrates superior durability compared to solid timber due to its engineered composition, which resists warping, splitting, and decay. The layering process in LVL enhances its structural integrity, leading to greater longevity in both indoor and outdoor applications. Solid timber, while natural and aesthetically appealing, is more susceptible to environmental factors such as moisture and pests, often resulting in a shorter lifespan.

Sustainability and Environmental Impact

Laminated Veneer Lumber (LVL) offers superior sustainability compared to solid timber by utilizing thin wood veneers glued together, which maximizes wood resource efficiency and reduces waste. LVL production often incorporates fast-growing, sustainably harvested wood species, lowering the environmental footprint relative to solid timber harvested from old-growth forests. Additionally, LVL's engineered design provides greater strength and dimensional stability, resulting in longer-lasting structures that reduce the demand for frequent replacements and further minimize carbon emissions.

Cost Analysis: LVL vs Solid Timber

Laminated Veneer Lumber (LVL) generally offers a more cost-effective solution compared to solid timber due to its engineered manufacturing process, which maximizes material efficiency and reduces waste. LVL provides consistent strength and dimensional stability, leading to lower labor and installation costs over time, whereas solid timber often requires additional treatment and quality grading that increases upfront expenses. Despite a higher initial price per cubic meter, LVL's long-term savings from reduced maintenance and superior performance make it a financially advantageous choice in structural applications.

Applications in Construction and Design

Laminated Veneer Lumber (LVL) offers superior strength and dimensional stability, making it ideal for long-span beams, columns, and structural framing in commercial and residential construction. Solid timber remains preferred for aesthetic-focused applications like exposed beams, flooring, and decorative elements where natural grain patterns are valued. Combining LVL's engineered uniformity with solid timber's visual appeal optimizes performance and design flexibility in modern architectural projects.

Workability and Installation Differences

Laminated Veneer Lumber (LVL) offers superior workability due to its engineered uniformity, allowing for precise cutting, drilling, and fastening compared to solid timber's natural variability. LVL's consistent strength and predictable dimensions simplify installation, reducing on-site adjustments and labor time. Solid timber requires more careful handling during installation to account for knots, grain patterns, and moisture-related changes impacting fit and fastener holding capacity.

Aesthetics: Appearance and Finishing Choices

Laminated Veneer Lumber (LVL) offers a more uniform and consistent grain pattern compared to Solid Timber, enhancing sleek and modern aesthetic designs. LVL's engineered composition allows for smoother finishes and greater flexibility in staining and painting, providing diverse customization options. Solid Timber, prized for its natural knots and unique grain variations, delivers a warm, authentic appearance that highlights the natural beauty of wood.

Laminated Veneer Lumber vs Solid Timber Infographic

materialdif.com

materialdif.com