Finish grade wood offers a smooth, high-quality surface ideal for visible pet furniture like dog beds and cat trees, enhancing both durability and aesthetic appeal. Construction grade wood provides sturdy support and structural integrity, perfect for the internal framework of pet enclosures or playgrounds. Choosing the right grade ensures your pet's environment is both safe and visually pleasing, balancing strength with finish.

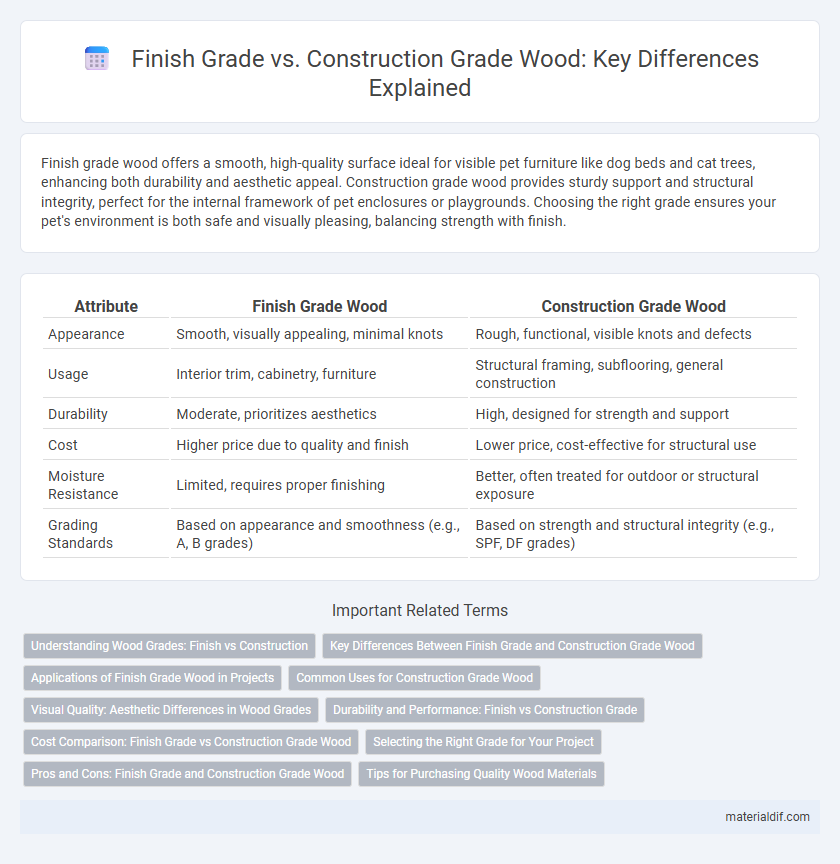

Table of Comparison

| Attribute | Finish Grade Wood | Construction Grade Wood |

|---|---|---|

| Appearance | Smooth, visually appealing, minimal knots | Rough, functional, visible knots and defects |

| Usage | Interior trim, cabinetry, furniture | Structural framing, subflooring, general construction |

| Durability | Moderate, prioritizes aesthetics | High, designed for strength and support |

| Cost | Higher price due to quality and finish | Lower price, cost-effective for structural use |

| Moisture Resistance | Limited, requires proper finishing | Better, often treated for outdoor or structural exposure |

| Grading Standards | Based on appearance and smoothness (e.g., A, B grades) | Based on strength and structural integrity (e.g., SPF, DF grades) |

Understanding Wood Grades: Finish vs Construction

Understanding wood grades is essential for selecting the right material; finish grade wood offers a smooth, defect-free surface ideal for visible applications like furniture and cabinetry, while construction grade wood prioritizes structural integrity, often including knots and imperfections suited for framing and building frameworks. Finish grade wood typically undergoes more rigorous inspection and higher quality standards, ensuring aesthetic appeal and easy finishing, whereas construction grade is evaluated primarily on strength and durability to support load-bearing purposes. Choosing between finish grade and construction grade wood depends on balancing appearance requirements with mechanical performance in your project.

Key Differences Between Finish Grade and Construction Grade Wood

Finish grade wood features smooth, defect-free surfaces ideal for visible applications such as cabinetry, trim, and furniture, enhancing aesthetic appeal and requiring minimal sanding or finishing. Construction grade wood contains more knots, splits, and imperfections, making it suitable for structural use where strength and durability are prioritized over appearance. The key difference lies in surface quality and intended purpose, with finish grade emphasizing visual perfection and construction grade focusing on function and cost-efficiency.

Applications of Finish Grade Wood in Projects

Finish grade wood offers superior quality with minimal defects, making it ideal for visible applications such as cabinetry, furniture, and interior trim. Its smooth surface and consistent appearance ensure enhanced aesthetic appeal and durability in residential and commercial projects. Contractors prefer finish grade wood for high-end finishes where precision and appearance are critical, distinguishing it from construction grade wood used primarily for structural and framing purposes.

Common Uses for Construction Grade Wood

Construction grade wood is primarily used in structural applications such as framing, subflooring, and roof decking due to its strength and affordability. It contains more knots and imperfections compared to finish grade, making it less suitable for visible surfaces but ideal for load-bearing purposes. Common wood species for construction grade include fir, pine, and spruce, favored for their durability and cost-effectiveness in building projects.

Visual Quality: Aesthetic Differences in Wood Grades

Finish grade wood offers a smooth, defect-free surface ideal for visible applications requiring high aesthetic appeal, such as cabinetry and fine furniture. Construction grade wood contains knots, splits, and other imperfections that do not affect structural integrity but compromise visual quality, making it suitable for framing and non-visible structural components. The choice between finish grade and construction grade wood significantly impacts the overall appearance and durability of wood projects.

Durability and Performance: Finish vs Construction Grade

Finish grade wood offers superior durability and a smoother surface ideal for visible applications due to its fine sanding and minimal defects. Construction grade wood, while structurally sound and more affordable, often contains knots and irregularities that can affect its long-term performance in exposed conditions. For projects requiring both aesthetic appeal and resilience, finish grade wood provides enhanced performance and longevity compared to the more utilitarian construction grade.

Cost Comparison: Finish Grade vs Construction Grade Wood

Finish grade wood typically costs more than construction grade wood due to its higher quality, smoother surface, and fewer defects, making it ideal for visible projects like cabinetry and furniture. Construction grade wood is more affordable and designed for structural purposes, often featuring knots and irregularities that don't affect its strength but reduce its aesthetic appeal. Choosing between the two depends on budget constraints and the project's visual demands, with construction grade offering economic efficiency and finish grade providing refined appearance at a premium price.

Selecting the Right Grade for Your Project

Finish grade wood is smooth, with minimal knots and defects, ideal for visible surfaces like furniture, cabinetry, and trim work. Construction grade wood is structural, featuring more knots and imperfections, suitable for framing, subfloors, and other structural components where strength is prioritized over appearance. Selecting the right grade depends on the project's function: choose finish grade for aesthetic appeal and construction grade for durability and support.

Pros and Cons: Finish Grade and Construction Grade Wood

Finish grade wood offers superior smoothness and minimal defects, making it ideal for visible applications like trim and cabinetry, but it comes at a higher cost and less structural strength. Construction grade wood is more affordable and structurally robust, suited for framing and support, though it often contains knots, splits, and a rougher surface. Choosing between the two depends on the balance of aesthetic requirements and structural needs in a project.

Tips for Purchasing Quality Wood Materials

When selecting wood materials, prioritize Finish Grade lumber for projects requiring smooth, high-quality surfaces and minimal defects, as it undergoes finer sanding and has fewer knots. Construction Grade wood suits structural applications where strength is critical, offering durability despite more visible imperfections. Always check for proper moisture content and certified grading stamps to ensure the wood meets industry standards and project requirements.

Finish Grade vs Construction Grade Infographic

materialdif.com

materialdif.com