Rift sawn wood features a consistent vertical grain pattern that enhances stability and reduces shrinkage, making it ideal for pet furniture that requires durability. Quarter sawn wood displays a distinctive ray fleck pattern with superior strength and warping resistance, perfect for long-lasting pet crates and enclosures. Choosing between rift sawn and quarter sawn wood depends on the desired aesthetic and functional qualities of the pet product.

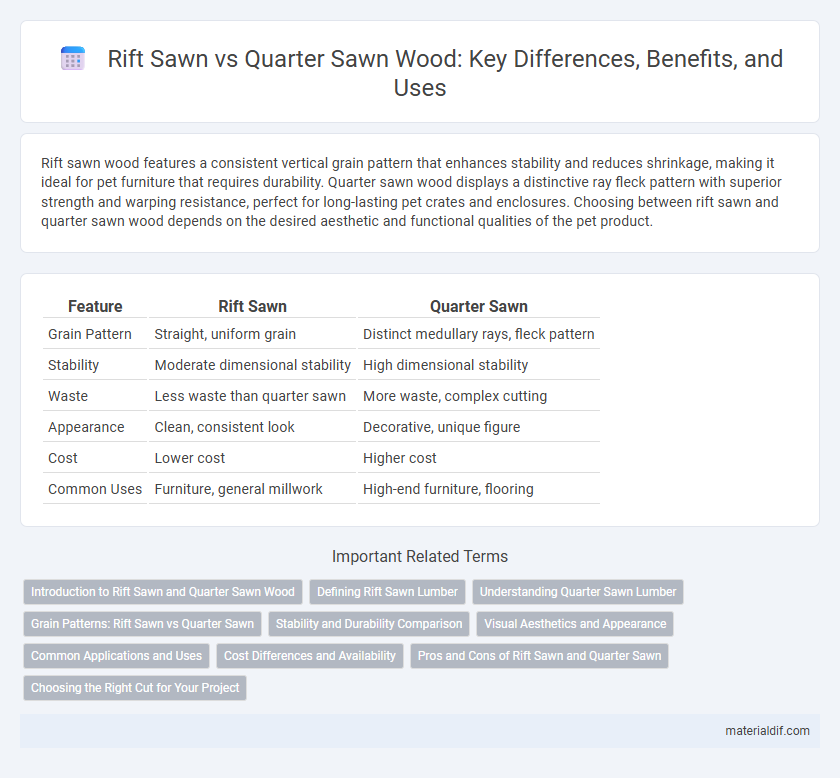

Table of Comparison

| Feature | Rift Sawn | Quarter Sawn |

|---|---|---|

| Grain Pattern | Straight, uniform grain | Distinct medullary rays, fleck pattern |

| Stability | Moderate dimensional stability | High dimensional stability |

| Waste | Less waste than quarter sawn | More waste, complex cutting |

| Appearance | Clean, consistent look | Decorative, unique figure |

| Cost | Lower cost | Higher cost |

| Common Uses | Furniture, general millwork | High-end furniture, flooring |

Introduction to Rift Sawn and Quarter Sawn Wood

Rift sawn wood is cut at a slight angle to the tree's growth rings, producing a straight grain pattern that enhances stability and reduces warping. Quarter sawn wood is sliced perpendicular to the growth rings, revealing a distinctive ray fleck pattern and offering superior resistance to cupping and twisting. Both sawing methods are prized for their structural integrity and aesthetic appeal, making them ideal choices for fine furniture and flooring.

Defining Rift Sawn Lumber

Rift sawn lumber is produced by cutting logs at a precise angle between the plain sawn and quarter sawn methods, typically at 30 to 60 degrees to the growth rings, resulting in a straight grain pattern with minimal fleck. This technique reduces wood distortion and enhances stability, making it ideal for furniture and flooring requiring uniform strength and appearance. Rift sawn wood is less susceptible to warping and swelling compared to plain sawn lumber, offering consistent dimensional stability over time.

Understanding Quarter Sawn Lumber

Quarter sawn lumber is produced by first cutting the log into quarters, then sawing each quarter perpendicular to the growth rings, resulting in wood boards with a straight grain pattern and increased stability. This method reduces warping and cupping, making it ideal for applications requiring durability and dimensional consistency, such as flooring and fine furniture. Compared to rift sawn lumber, quarter sawn wood displays prominent medullary rays, enhancing both structural integrity and aesthetic appeal.

Grain Patterns: Rift Sawn vs Quarter Sawn

Rift sawn wood exhibits a straight, uniform grain pattern with minimal flecking, making it ideal for clean, linear aesthetics in furniture and flooring. Quarter sawn wood displays a distinct ray fleck pattern and a tighter grain, offering enhanced stability and a decorative appearance favored in fine cabinetry and musical instruments. Understanding these grain differences helps in selecting the appropriate cut for both visual appeal and functional durability in wood projects.

Stability and Durability Comparison

Rift sawn wood offers superior dimensional stability with minimal warping and cupping due to its vertical grain alignment, making it ideal for precise woodworking projects. Quarter sawn wood provides enhanced durability and resistance to wear, featuring medullary rays that create a distinct grain pattern and improve strength. Both cuts excel in stability and longevity, but quarter sawn lumber typically outperforms rift sawn in resisting moisture-induced movement and structural deformation.

Visual Aesthetics and Appearance

Rift sawn wood displays a straight, uniform grain pattern with minimal flecking, offering a clean and consistent visual aesthetic ideal for modern designs. Quarter sawn wood features a distinctive medullary ray pattern that creates a rich, decorative texture and enhances light reflection, prized for traditional and upscale furniture. Both cuts improve dimensional stability, but quarter sawn is often favored for its intricate appearance and elegance in fine woodworking.

Common Applications and Uses

Rift sawn wood is commonly used for furniture, flooring, and cabinetry due to its uniform grain pattern and resistance to warping. Quarter sawn lumber is preferred in applications requiring stability and aesthetic appeal, such as fine furniture, musical instruments, and architectural millwork. Both sawing methods enhance durability, but quarter sawn wood offers superior resistance to cupping and is often chosen for high-end woodworking projects.

Cost Differences and Availability

Rift sawn wood generally costs less than quarter sawn due to lower yield and simpler milling processes, making it more widely available for furniture and flooring. Quarter sawn lumber, prized for its stability and distinctive grain pattern, commands a premium price and is less abundant because it requires precise cutting and yields narrower boards. Availability varies regionally, but quarter sawn wood remains a specialty product often sourced from high-quality hardwoods like oak and maple.

Pros and Cons of Rift Sawn and Quarter Sawn

Rift sawn wood offers a consistent grain pattern and exceptional stability, making it ideal for furniture and flooring that require minimal warping. However, it produces more waste and can be more costly compared to quarter sawn wood. Quarter sawn wood provides superior resistance to cupping and enhances visual appeal with its distinctive medullary ray figures but may have varied grain patterns and is generally less uniform than rift sawn lumber.

Choosing the Right Cut for Your Project

Rift sawn wood features a consistent, linear grain pattern ideal for modern furniture and cabinetry, offering increased stability and minimal warping. Quarter sawn wood displays dramatic, medullary ray patterns, enhancing aesthetic appeal and structural strength, making it perfect for flooring and musical instruments. Selecting the right cut depends on the project's visual preferences and durability requirements, with rift sawn suited for uniformity and quarter sawn favored for decorative grain complexity.

Rift sawn vs Quarter sawn Infographic

materialdif.com

materialdif.com