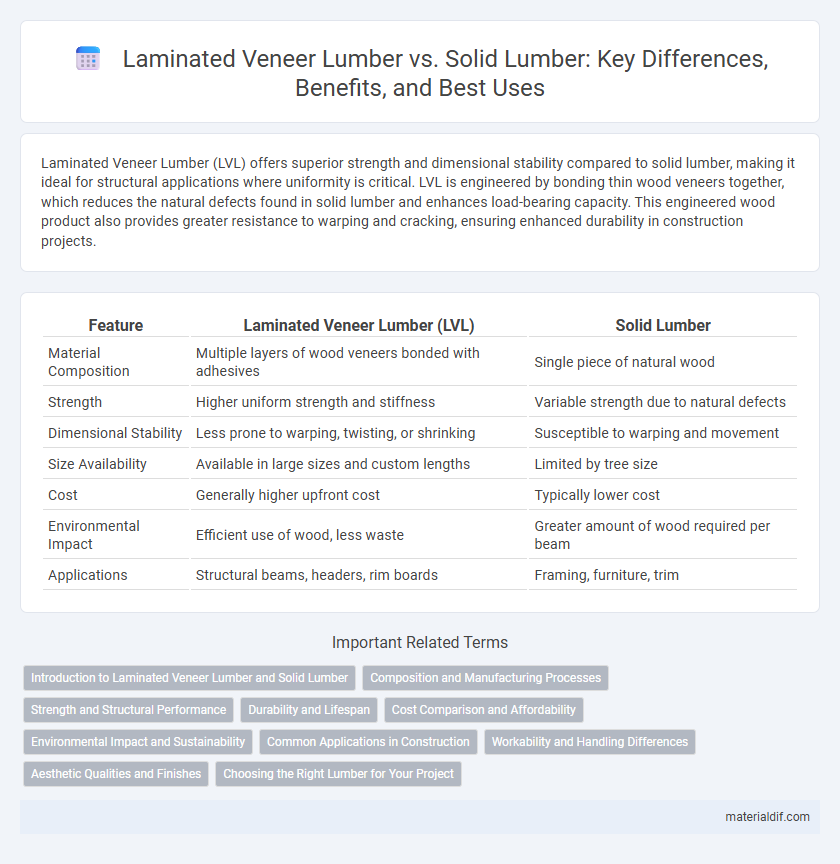

Laminated Veneer Lumber (LVL) offers superior strength and dimensional stability compared to solid lumber, making it ideal for structural applications where uniformity is critical. LVL is engineered by bonding thin wood veneers together, which reduces the natural defects found in solid lumber and enhances load-bearing capacity. This engineered wood product also provides greater resistance to warping and cracking, ensuring enhanced durability in construction projects.

Table of Comparison

| Feature | Laminated Veneer Lumber (LVL) | Solid Lumber |

|---|---|---|

| Material Composition | Multiple layers of wood veneers bonded with adhesives | Single piece of natural wood |

| Strength | Higher uniform strength and stiffness | Variable strength due to natural defects |

| Dimensional Stability | Less prone to warping, twisting, or shrinking | Susceptible to warping and movement |

| Size Availability | Available in large sizes and custom lengths | Limited by tree size |

| Cost | Generally higher upfront cost | Typically lower cost |

| Environmental Impact | Efficient use of wood, less waste | Greater amount of wood required per beam |

| Applications | Structural beams, headers, rim boards | Framing, furniture, trim |

Introduction to Laminated Veneer Lumber and Solid Lumber

Laminated Veneer Lumber (LVL) is an engineered wood product made by layering thin wood veneers with adhesives, creating a strong and uniform material ideal for structural applications like beams and headers. Solid lumber, derived directly from sawn logs, offers natural strength and aesthetic grain patterns but can be prone to warping and splitting under varying conditions. LVL provides enhanced stability and strength consistency compared to solid lumber, making it a preferred choice in modern construction for load-bearing elements.

Composition and Manufacturing Processes

Laminated Veneer Lumber (LVL) consists of multiple thin wood veneers bonded together with adhesives under heat and pressure, providing enhanced strength and uniformity compared to Solid Lumber, which is cut directly from a single tree log. The manufacturing process of LVL involves precise layering and alignment of veneers to optimize grain direction and structural properties, while Solid Lumber retains natural variations and defects inherent in the wood species. LVL offers superior dimensional stability and load-bearing capacity due to its engineered composition, making it ideal for high-performance construction applications.

Strength and Structural Performance

Laminated Veneer Lumber (LVL) offers superior strength and consistent structural performance compared to solid lumber due to its engineered assembly of multiple wood veneers bonded under heat and pressure. LVL exhibits higher load-bearing capacity, improved dimensional stability, and reduced susceptibility to warping or splitting, making it ideal for beams, headers, and joists in construction. Solid lumber varies in strength depending on knot presence and grain direction, often resulting in less predictable performance under structural stress.

Durability and Lifespan

Laminated Veneer Lumber (LVL) offers superior durability compared to solid lumber due to its engineered structure, which resists warping, splitting, and twisting. LVL's consistent quality and moisture-resistant adhesive layers contribute to a longer lifespan, often exceeding 50 years in structural applications. Solid lumber, while natural and strong, is more susceptible to environmental factors such as rot, insect damage, and dimensional instability, typically resulting in a shorter service life.

Cost Comparison and Affordability

Laminated Veneer Lumber (LVL) generally offers a more cost-effective solution compared to solid lumber due to its engineered production process that maximizes yield from timber. LVL provides consistent strength and dimensions, reducing waste and labor costs, which contributes to overall affordability in construction projects. While solid lumber can be cheaper upfront, laminated veneer lumber's durability and stability often result in lower lifecycle expenses and better value for budget-conscious builders.

Environmental Impact and Sustainability

Laminated Veneer Lumber (LVL) demonstrates a lower environmental impact compared to solid lumber due to its efficient use of smaller, faster-growing trees and reduced waste through engineered processing. LVL's production consumes less energy and generates fewer greenhouse gas emissions, enhancing its sustainability profile in construction. Solid lumber, while renewable, often requires harvesting larger, older trees, contributing to higher ecological disturbance and slower forest regeneration.

Common Applications in Construction

Laminated Veneer Lumber (LVL) is frequently used for beams, headers, and rim boards in residential and commercial construction due to its high strength-to-weight ratio and consistent quality. Solid lumber remains popular for framing, flooring, and exterior applications where natural wood grain and traditional aesthetics are desired. LVL's engineered properties make it ideal for long spans and load-bearing structures, whereas solid lumber is favored for ease of cutting and onsite modifications.

Workability and Handling Differences

Laminated Veneer Lumber (LVL) offers superior workability compared to solid lumber due to its engineered uniformity and consistent density, enabling precise cutting and shaping with minimal splintering. LVL's lightweight nature and predictable structural properties simplify handling on-site, while solid lumber can present variability in grain patterns and moisture content, making it more challenging to manipulate. For construction projects requiring repetitive cuts and complex joinery, LVL provides enhanced efficiency and reduced labor effort.

Aesthetic Qualities and Finishes

Laminated Veneer Lumber (LVL) offers a more uniform appearance with consistent grain patterns due to its engineered layers, making it ideal for modern, sleek finishes. Solid lumber showcases natural variations, knots, and textures that appeal to rustic and traditional aesthetics, providing a unique character to each piece. LVL typically allows for smoother finishes and better paint adhesion, while solid lumber offers richer stains and a more natural tactile feel.

Choosing the Right Lumber for Your Project

Laminated Veneer Lumber (LVL) offers superior strength, dimensional stability, and resistance to warping compared to solid lumber, making it ideal for structural applications such as beams and headers. Solid lumber provides natural aesthetics and is often preferred for visible finishes in furniture and decorative projects. Selecting the right lumber depends on project requirements like load-bearing capacity, durability, and visual appeal to ensure optimal performance and longevity.

Laminated Veneer Lumber vs Solid Lumber Infographic

materialdif.com

materialdif.com