Finger jointed wood offers enhanced strength and stability by interlocking multiple fingers to create a larger surface area for adhesive bonding, resulting in a more durable connection compared to butt jointed wood. Butt jointed wood, on the other hand, joins two pieces end-to-end without additional interlocking features, making it simpler but less robust and more prone to separation under stress. Choosing finger jointed wood improves structural integrity and reduces material waste, making it ideal for furniture and construction applications requiring long-lasting performance.

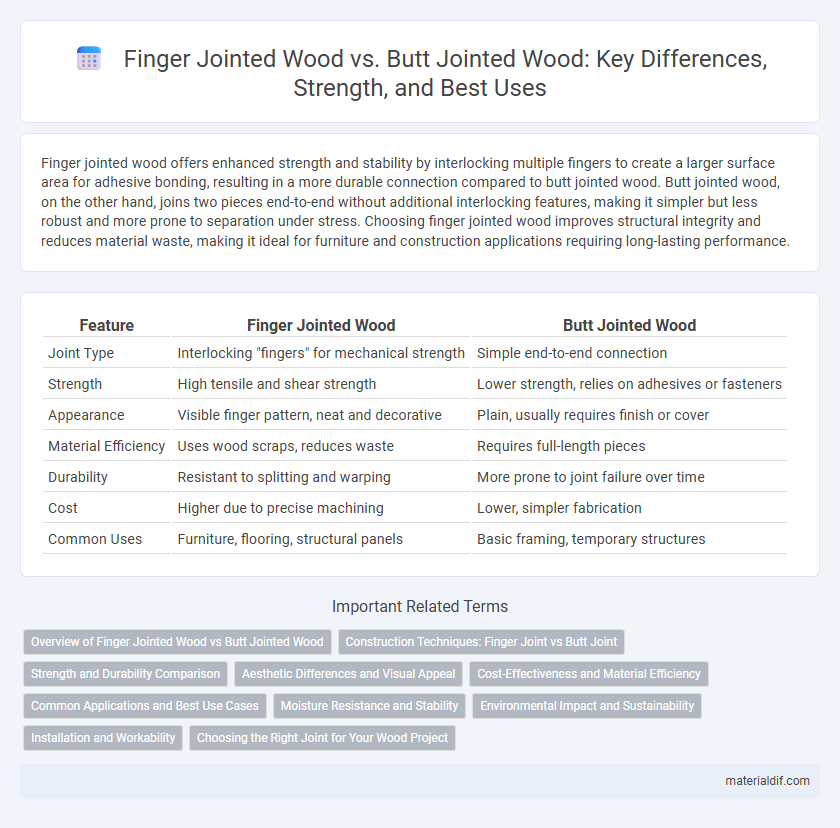

Table of Comparison

| Feature | Finger Jointed Wood | Butt Jointed Wood |

|---|---|---|

| Joint Type | Interlocking "fingers" for mechanical strength | Simple end-to-end connection |

| Strength | High tensile and shear strength | Lower strength, relies on adhesives or fasteners |

| Appearance | Visible finger pattern, neat and decorative | Plain, usually requires finish or cover |

| Material Efficiency | Uses wood scraps, reduces waste | Requires full-length pieces |

| Durability | Resistant to splitting and warping | More prone to joint failure over time |

| Cost | Higher due to precise machining | Lower, simpler fabrication |

| Common Uses | Furniture, flooring, structural panels | Basic framing, temporary structures |

Overview of Finger Jointed Wood vs Butt Jointed Wood

Finger jointed wood features interlocking finger-like projections that increase surface area, resulting in stronger, more durable joints compared to butt jointed wood, which simply aligns end grains without interlocking. This technique enhances dimensional stability and reduces warping, making finger jointed wood ideal for structural applications and fine woodworking. In contrast, butt joints are easier and faster to produce but typically require additional reinforcement to achieve comparable strength.

Construction Techniques: Finger Joint vs Butt Joint

Finger jointed wood involves interlocking multiple "fingers" or projections from two pieces, creating a stronger, more stable connection that enhances load-bearing capacity and resistance to warping. Butt jointed wood simply joins two flat ends together, relying primarily on glue or fasteners, resulting in a weaker bond with less structural integrity. Finger joint construction is preferred in furniture and cabinetry for durability, while butt joints are common in basic framing or temporary structures where ease and speed are prioritized.

Strength and Durability Comparison

Finger jointed wood exhibits superior strength and durability compared to butt jointed wood due to its interlocking design, which distributes stress evenly across the joint. The increased surface area in finger joints allows for stronger adhesive bonds, enhancing resistance to mechanical forces and reducing the likelihood of joint failure. Butt joints rely primarily on surface contact with adhesive, making them weaker and less durable under load and environmental changes.

Aesthetic Differences and Visual Appeal

Finger jointed wood features interlocking fingers that create a visually intricate pattern, enhancing the overall aesthetic with a sense of craftsmanship and texture variation. Butt jointed wood presents a simpler, more uniform appearance with straight edges meeting cleanly, offering a minimalist and seamless look. The choice between finger jointed and butt jointed wood significantly impacts the visual appeal, with finger joints adding decorative interest and butt joints emphasizing smoothness and simplicity.

Cost-Effectiveness and Material Efficiency

Finger jointed wood offers superior cost-effectiveness by maximizing material usage through interlocking joints that reduce waste and enhance structural strength. Butt jointed wood, while simpler and quicker to assemble, often results in higher material wastage and less durability, increasing long-term expenses. The precision of finger joints allows for efficient utilization of smaller wood pieces, making it a more economical choice for large-scale woodworking projects.

Common Applications and Best Use Cases

Finger jointed wood is commonly utilized in furniture making, moldings, and door frames due to its enhanced strength and stability, making it ideal for load-bearing and decorative applications. Butt jointed wood is frequently used in simple frame constructions, cabinetry, and temporary structures where ease of assembly and cost-effectiveness are prioritized over joint strength. Finger joints provide superior resistance to warping and splitting, best suited for structural components, while butt joints serve well in non-structural applications with minimal stress requirements.

Moisture Resistance and Stability

Finger jointed wood exhibits superior moisture resistance and dimensional stability compared to butt jointed wood due to its interlocking joint design that reduces gaps and resists warping. The increased surface area of finger joints allows for stronger adhesive bonding, minimizing water infiltration and enhancing structural integrity in humid conditions. Butt jointed wood, with simple end-to-end connections, is more prone to moisture absorption and expansion, leading to decreased stability and a higher risk of joint failure over time.

Environmental Impact and Sustainability

Finger jointed wood enhances sustainability by utilizing shorter wood pieces that reduce waste and optimize raw material use, leading to efficient forest resource management. Butt jointed wood, often less structurally stable, may require additional materials or treatments that increase environmental footprint and reduce lifecycle sustainability. The manufacturing process of finger jointing promotes recycling and lowers energy consumption compared to butt jointing, making it a more eco-friendly choice in wood construction.

Installation and Workability

Finger jointed wood offers superior installation ease due to its interlocking design, which ensures stronger mechanical bonds and better alignment compared to butt jointed wood. Butt jointed wood requires more precise fastening techniques and often additional reinforcement to achieve stability, making it less efficient in terms of workability. The enhanced surface area of finger joints allows for improved glue adhesion, reducing installation time and increasing overall joint durability.

Choosing the Right Joint for Your Wood Project

Finger jointed wood offers enhanced strength and stability through interlocking teeth that increase gluing surface area, making it ideal for load-bearing or long-span applications. Butt jointed wood relies on simple end-to-end contact, providing a faster, more economical option suited for non-structural or decorative projects where appearance is less critical. Selecting the right joint depends on the required strength, aesthetic demands, and project budget, with finger joints excelling in durability and butt joints favoring simplicity.

Finger Jointed Wood vs Butt Jointed Wood Infographic

materialdif.com

materialdif.com