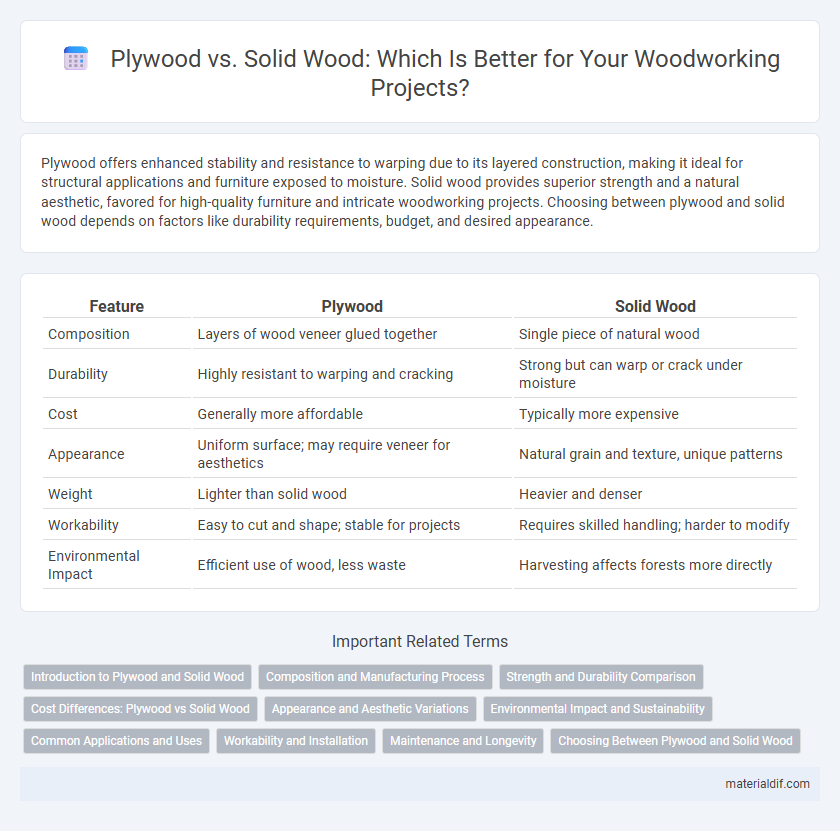

Plywood offers enhanced stability and resistance to warping due to its layered construction, making it ideal for structural applications and furniture exposed to moisture. Solid wood provides superior strength and a natural aesthetic, favored for high-quality furniture and intricate woodworking projects. Choosing between plywood and solid wood depends on factors like durability requirements, budget, and desired appearance.

Table of Comparison

| Feature | Plywood | Solid Wood |

|---|---|---|

| Composition | Layers of wood veneer glued together | Single piece of natural wood |

| Durability | Highly resistant to warping and cracking | Strong but can warp or crack under moisture |

| Cost | Generally more affordable | Typically more expensive |

| Appearance | Uniform surface; may require veneer for aesthetics | Natural grain and texture, unique patterns |

| Weight | Lighter than solid wood | Heavier and denser |

| Workability | Easy to cut and shape; stable for projects | Requires skilled handling; harder to modify |

| Environmental Impact | Efficient use of wood, less waste | Harvesting affects forests more directly |

Introduction to Plywood and Solid Wood

Plywood is an engineered wood product made by gluing together thin layers of wood veneer, offering enhanced strength and stability compared to solid wood. Solid wood consists of natural timber cut directly from trees, prized for its durability, natural grain patterns, and aesthetic appeal. Choosing between plywood and solid wood depends on factors like application, cost, and structural requirements.

Composition and Manufacturing Process

Plywood consists of multiple thin layers of wood veneers glued together with the grain of each layer oriented perpendicular to the adjacent one, enhancing strength and reducing warping. Solid wood is made from a single piece of timber, providing natural durability but is more prone to expanding and contracting with moisture changes. The manufacturing process of plywood involves pressing and bonding layers under heat and pressure, while solid wood requires cutting and finishing without additional lamination.

Strength and Durability Comparison

Plywood offers superior strength and durability compared to solid wood due to its engineered cross-grain layers that resist warping, cracking, and splitting. Solid wood provides natural toughness but is more susceptible to environmental changes, leading to potential deformation over time. The layered construction of plywood enhances load-bearing capacity, making it ideal for structural applications requiring consistent stability.

Cost Differences: Plywood vs Solid Wood

Plywood generally costs less than solid wood due to its manufacturing process, which uses thin layers of wood veneer glued together, maximizing material efficiency and reducing waste. Solid wood prices vary significantly based on species, grain quality, and sourcing, often making it more expensive, especially for hardwood varieties like oak or maple. The cost-effectiveness of plywood makes it a popular choice for budget-conscious projects without compromising structural strength.

Appearance and Aesthetic Variations

Plywood offers a more uniform and consistent appearance due to its layered construction, making it ideal for modern, clean-lined designs. Solid wood displays natural grain patterns and color variations that provide a rich, authentic aesthetic, highly valued for traditional and rustic styles. The choice between plywood and solid wood impacts the visual texture and warmth of furniture or cabinetry, influencing overall interior design harmony.

Environmental Impact and Sustainability

Plywood, made from thin layers of wood veneer glued together, typically uses smaller trees and wood from fast-growing species, reducing deforestation compared to solid wood sourced from large, mature trees. The production of plywood often involves adhesives that can emit volatile organic compounds (VOCs), posing environmental concerns, whereas solid wood is naturally VOC-free and biodegradable. Sustainable sourcing certifications like FSC for both materials help ensure responsible forestry practices, but plywood's efficient use of wood resources generally results in a lower carbon footprint and less waste.

Common Applications and Uses

Plywood is widely used in construction for subfloors, wall and roof sheathing, and furniture due to its strength, stability, and resistance to warping. Solid wood is preferred in cabinetry, flooring, and fine woodworking projects where natural grain and durability are paramount. Both materials serve distinct purposes: plywood offers cost-effective, flexible solutions for structural use, while solid wood provides aesthetic appeal and long-term durability in finished products.

Workability and Installation

Plywood offers superior workability due to its layered construction, allowing for easier cutting, shaping, and resistance to warping compared to solid wood. Installation of plywood is typically faster and more straightforward, as it maintains structural stability even when fastened with screws or nails. Solid wood requires careful handling to prevent splitting and may involve more complex joinery techniques, making installation more time-consuming.

Maintenance and Longevity

Plywood offers enhanced resistance to warping, cracking, and moisture damage compared to solid wood, resulting in lower maintenance requirements over time. Solid wood can require regular sealing, polishing, and protection from environmental factors to maintain its appearance and structural integrity. In terms of longevity, high-quality plywood tends to retain its strength and shape longer in humid or variable conditions, while solid wood, when properly cared for, can develop a rich patina and last for generations.

Choosing Between Plywood and Solid Wood

Choosing between plywood and solid wood depends on factors such as durability, cost, and application. Plywood offers enhanced stability and resistance to warping due to its layered construction, making it ideal for structural uses and large surfaces. Solid wood provides natural beauty and strength, preferred for furniture and high-end woodworking projects where aesthetic and longevity are priorities.

Plywood vs Solid Wood Infographic

materialdif.com

materialdif.com