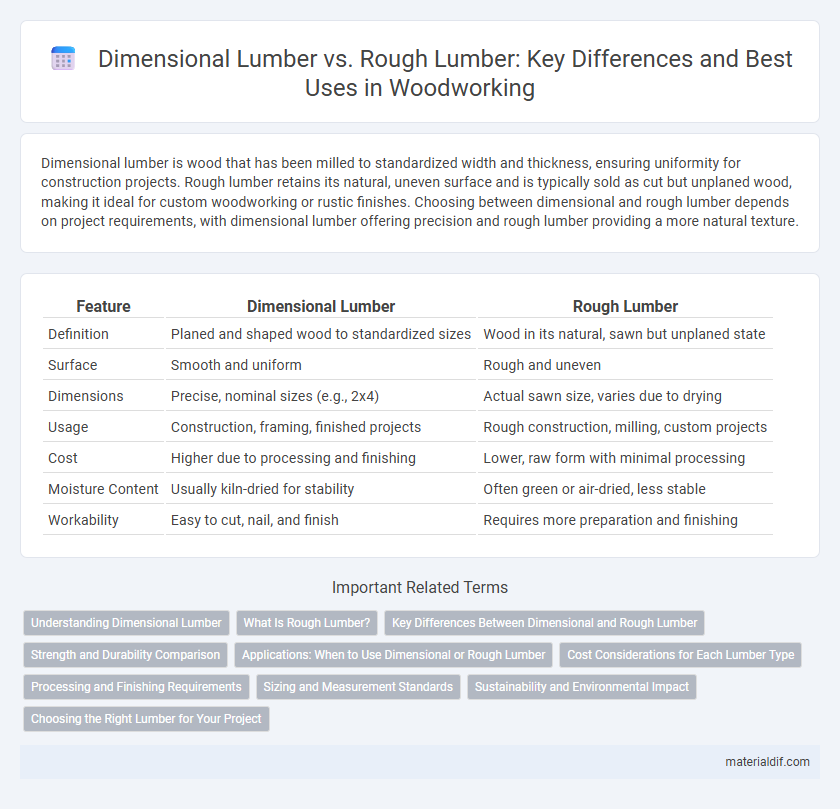

Dimensional lumber is wood that has been milled to standardized width and thickness, ensuring uniformity for construction projects. Rough lumber retains its natural, uneven surface and is typically sold as cut but unplaned wood, making it ideal for custom woodworking or rustic finishes. Choosing between dimensional and rough lumber depends on project requirements, with dimensional lumber offering precision and rough lumber providing a more natural texture.

Table of Comparison

| Feature | Dimensional Lumber | Rough Lumber |

|---|---|---|

| Definition | Planed and shaped wood to standardized sizes | Wood in its natural, sawn but unplaned state |

| Surface | Smooth and uniform | Rough and uneven |

| Dimensions | Precise, nominal sizes (e.g., 2x4) | Actual sawn size, varies due to drying |

| Usage | Construction, framing, finished projects | Rough construction, milling, custom projects |

| Cost | Higher due to processing and finishing | Lower, raw form with minimal processing |

| Moisture Content | Usually kiln-dried for stability | Often green or air-dried, less stable |

| Workability | Easy to cut, nail, and finish | Requires more preparation and finishing |

Understanding Dimensional Lumber

Dimensional lumber refers to wood that has been milled to standard thicknesses and widths, typically used in framing and construction projects for consistency and ease of measurement. It comes in uniform sizes such as 2x4, 2x6, and 4x4, providing predictable structural strength and simplified planning. Unlike rough lumber, which retains its natural, uneven surfaces and dimensions, dimensional lumber is planed smooth and precisely cut to industry standards, facilitating faster building processes and reliable fitting.

What Is Rough Lumber?

Rough lumber refers to wood that has been sawn but remains unfinished and unplaned, retaining a coarse texture and natural edges. It typically measures larger than finished dimensions, requiring further processing before use in construction or woodworking projects. This type of lumber is favored for its rustic appearance and is often used in applications where surface smoothness is not critical.

Key Differences Between Dimensional and Rough Lumber

Dimensional lumber is uniformly cut and planed to standardized sizes like 2x4 or 2x6, ensuring smooth surfaces and precise dimensions ideal for construction and framing. Rough lumber, in contrast, is sawn but not planed, retaining a rough finish and variable thickness that requires further processing before use in projects demanding exact measurements. The key differences lie in surface texture, dimensional accuracy, and typical applications, with dimensional lumber preferred for structural consistency and rough lumber often used where appearance is secondary or for rustic aesthetics.

Strength and Durability Comparison

Dimensional lumber offers uniform strength and consistent durability due to standardized milling and moisture control, making it ideal for structural applications. Rough lumber retains its natural surface texture and may exhibit variable strength and durability because of uneven drying and lack of precise machining. Builders often prefer dimensional lumber for reliable load-bearing performance, while rough lumber is chosen for aesthetic or rustic purposes despite potential strength inconsistencies.

Applications: When to Use Dimensional or Rough Lumber

Dimensional lumber is ideal for precise construction projects such as framing walls, furniture making, and cabinetry due to its uniform size and smooth finish. Rough lumber is preferred in applications where rustic aesthetics or structural strength outweigh appearance, like outdoor fencing, posts, and heavy-duty framing. Choosing between dimensional and rough lumber depends on whether accuracy and appearance or raw strength and cost-effectiveness are the primary requirements.

Cost Considerations for Each Lumber Type

Dimensional lumber, typically milled to standard sizes and smooth finishes, often carries a higher price due to the processing involved, making it ideal for projects requiring precise measurements and ease of use. Rough lumber, less processed and retaining its natural texture, is generally more cost-effective, appealing to builders who prioritize budget and are equipped for additional planing or finishing. Cost considerations hinge on project requirements, with dimensional lumber offering time savings and consistency, while rough lumber provides raw material savings at the expense of additional labor.

Processing and Finishing Requirements

Dimensional lumber undergoes precise milling and planing to standardized sizes and smooth surfaces, ensuring uniformity and ease of use in construction projects. Rough lumber, harvested directly from logs, retains a coarse texture and irregular dimensions, requiring additional processing such as planing, sanding, and trimming before it can be incorporated into finished products. The finishing requirements for dimensional lumber are minimal compared to rough lumber, making dimensional lumber more suitable for applications demanding consistency and immediate usability.

Sizing and Measurement Standards

Dimensional lumber is precisely cut to standardized sizes such as 2x4 inches, following strict grading and measurement standards set by organizations like the American Softwood Lumber Standard (PS 20). Rough lumber, however, refers to wood in its initial sawn state, often irregular in size and measured in nominal dimensions before planing or finishing. Understanding these differences is crucial for accurate material estimation and ensuring compatibility with building codes and construction specifications.

Sustainability and Environmental Impact

Dimensional lumber, typically kiln-dried and planed for uniformity, tends to have a lower environmental impact due to reduced waste in construction processes compared to rough lumber, which requires additional onsite processing and trimming. Sustainable forestry practices enhance the benefits of dimensional lumber by optimizing tree yield and minimizing deforestation, whereas rough lumber often originates from less processed logs, potentially leading to inefficient use of timber resources. Choosing dimensional lumber sourced from certified sustainable forests supports carbon sequestration efforts and reduces landfill waste caused by excess wood offcuts.

Choosing the Right Lumber for Your Project

Dimensional lumber is precisely cut and planed to standardized sizes, making it ideal for framing and finishing projects requiring uniformity and ease of assembly. Rough lumber retains its natural, uneven surfaces and is typically less expensive, offering greater flexibility for custom woodworking or rustic designs. Selecting the right wood depends on the specific structural needs, aesthetic goals, and budget constraints of your project.

Dimensional Lumber vs Rough Lumber Infographic

materialdif.com

materialdif.com