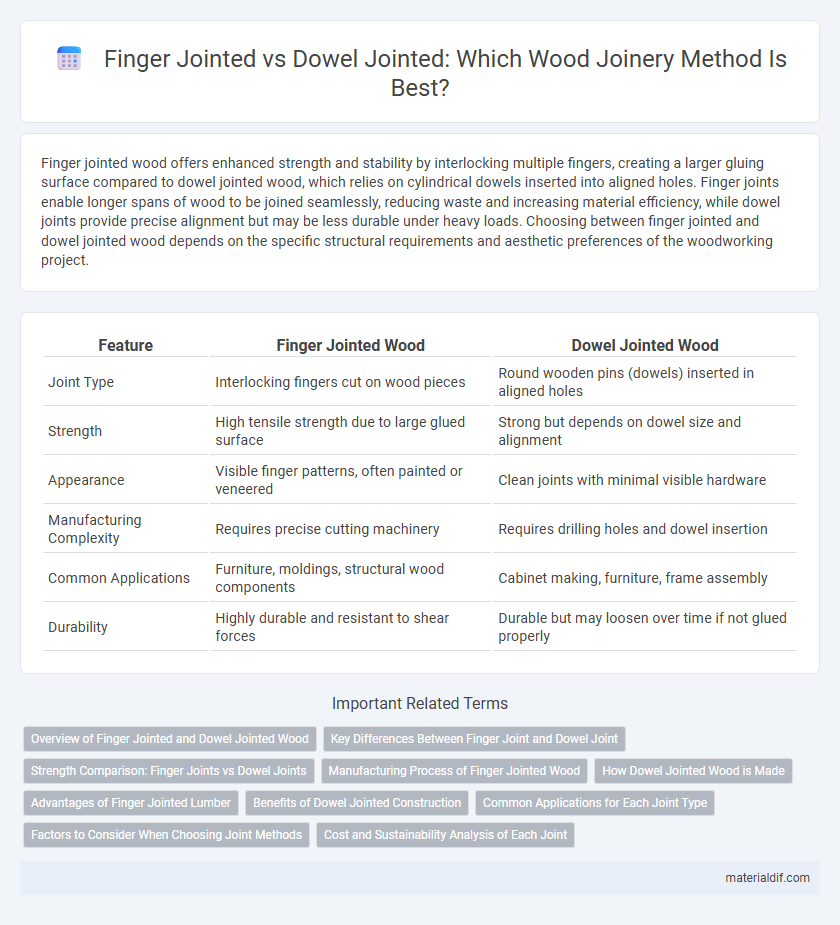

Finger jointed wood offers enhanced strength and stability by interlocking multiple fingers, creating a larger gluing surface compared to dowel jointed wood, which relies on cylindrical dowels inserted into aligned holes. Finger joints enable longer spans of wood to be joined seamlessly, reducing waste and increasing material efficiency, while dowel joints provide precise alignment but may be less durable under heavy loads. Choosing between finger jointed and dowel jointed wood depends on the specific structural requirements and aesthetic preferences of the woodworking project.

Table of Comparison

| Feature | Finger Jointed Wood | Dowel Jointed Wood |

|---|---|---|

| Joint Type | Interlocking fingers cut on wood pieces | Round wooden pins (dowels) inserted in aligned holes |

| Strength | High tensile strength due to large glued surface | Strong but depends on dowel size and alignment |

| Appearance | Visible finger patterns, often painted or veneered | Clean joints with minimal visible hardware |

| Manufacturing Complexity | Requires precise cutting machinery | Requires drilling holes and dowel insertion |

| Common Applications | Furniture, moldings, structural wood components | Cabinet making, furniture, frame assembly |

| Durability | Highly durable and resistant to shear forces | Durable but may loosen over time if not glued properly |

Overview of Finger Jointed and Dowel Jointed Wood

Finger jointed wood consists of multiple short pieces of wood joined end-to-end using interlocking fingers and adhesive, creating long, stable boards ideal for structural applications and furniture. Dowel jointed wood involves cylindrical wooden pins inserted into corresponding holes in adjoining pieces to form strong, precise connections commonly used in cabinetry and frame construction. Both methods enhance wood stability and resource efficiency but differ in assembly technique and application suitability.

Key Differences Between Finger Joint and Dowel Joint

Finger jointed wood features interlocking fingers cut into the ends of pieces, providing increased surface area for adhesive bonding and superior tensile strength, making it ideal for long, straight components. Dowel joints use cylindrical wooden pins inserted into aligned holes in adjoining pieces, offering precise alignment and moderate shear strength, commonly employed in furniture assembly where ease of disassembly may be beneficial. Finger joints excel in load-bearing applications and large panel construction, whereas dowel joints are preferred for smaller assemblies with frequent handling or repair requirements.

Strength Comparison: Finger Joints vs Dowel Joints

Finger joints offer superior tensile strength and resistance to bending compared to dowel joints due to the increased gluing surface area and interlocking design. Dowel joints rely on cylindrical pins that provide moderate shear strength but less surface contact for adhesive bonding. In applications requiring high load-bearing capacity and durability, finger joints typically outperform dowel joints in structural integrity.

Manufacturing Process of Finger Jointed Wood

The manufacturing process of finger jointed wood involves precisely cutting interlocking profile fingers on the ends of short wood pieces using specialized machinery, ensuring a strong and stable bond when glued together. This method enables the efficient use of smaller or defected wood sections by joining them into longer, uniform lengths with improved structural integrity. Automated production lines incorporate accurate finger profiling, adhesive application, and pressing stages to create finger jointed lumber suitable for furniture, moldings, and construction purposes.

How Dowel Jointed Wood is Made

Doweling joint construction involves drilling precise, evenly spaced holes into two wooden pieces and inserting cylindrical wooden dowels coated with wood glue to create a strong, aligned bond. The dowels act as internal reinforcements that enhance joint strength and stability, ensuring resistance to twisting and pulling forces. This method is commonly used in furniture making for its ability to produce durable, clean-looking joints without visible fasteners.

Advantages of Finger Jointed Lumber

Finger jointed lumber offers superior strength and stability compared to dowel jointed wood due to its increased gluing surface and interlocking design. This method minimizes wood waste by utilizing shorter wood pieces, enhancing sustainability and cost efficiency. Its resistance to warping and splitting makes finger jointed lumber ideal for structural applications in furniture and millwork.

Benefits of Dowel Jointed Construction

Dowel jointed construction provides superior alignment and strength compared to finger jointed wood due to the precise fitting of cylindrical wooden pins into corresponding holes, which creates a robust mechanical bond. This method enhances the load-bearing capacity and resistance to twisting forces, making it ideal for furniture and structural applications requiring durability. The dowel joint also offers a cleaner aesthetic with minimal visible gaps, contributing to a polished, professional finish in woodworking projects.

Common Applications for Each Joint Type

Finger jointed wood is commonly used in manufacturing furniture panels, moldings, and door frames due to its ability to create long, stable pieces from shorter wood segments. Dowel jointed wood is frequently applied in cabinetry, chair construction, and drawer assemblies where strong, precise alignment is essential. Both joint types enhance structural integrity but are chosen based on specific load-bearing and aesthetic requirements in woodworking projects.

Factors to Consider When Choosing Joint Methods

Selecting between finger jointed and dowel jointed wood requires evaluating factors like structural strength, application purpose, and aesthetic appeal. Finger joints provide enhanced surface area for glue, making them ideal for long, straight edges and ensuring durability under stress. Dowel joints offer precise alignment suitable for corner joints and areas demanding concealed fastening, but may require more intricate machining and careful fitting.

Cost and Sustainability Analysis of Each Joint

Finger jointed wood typically offers a more cost-effective solution due to its efficient use of shorter wood pieces and automated production, reducing waste and labor expenses. Dowel jointed wood, while often stronger and more durable, involves higher costs from precise machining and the use of metal or wooden dowels, increasing material and assembly expenses. From a sustainability perspective, finger joints optimize wood utilization and enable recycling of smaller wood fragments, whereas dowel joints may produce more offcuts and require additional resources, slightly impacting environmental footprint.

Finger Jointed vs Dowel Jointed Infographic

materialdif.com

materialdif.com