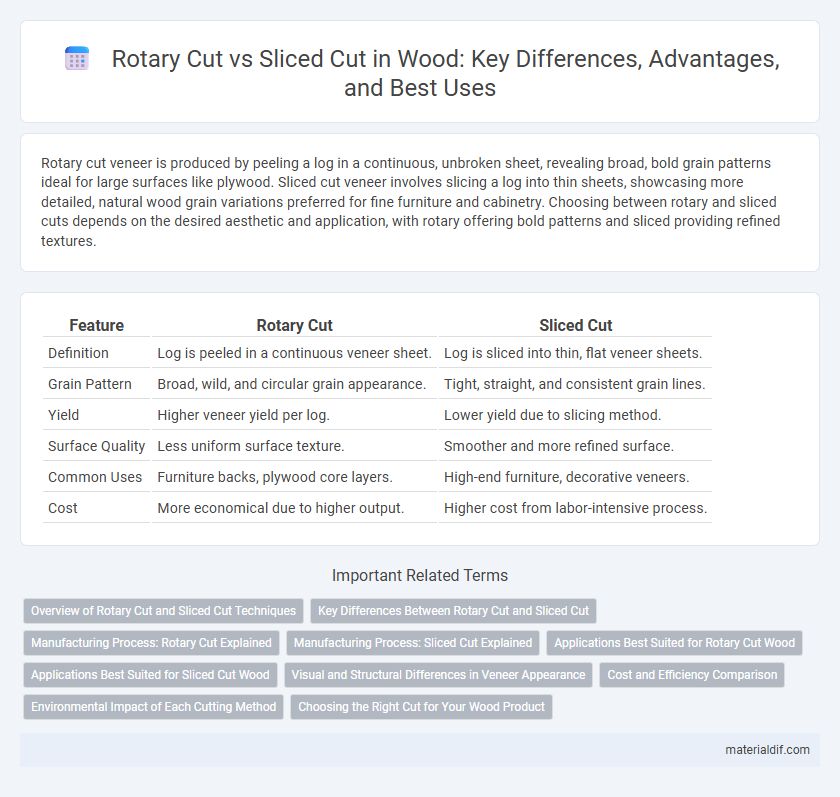

Rotary cut veneer is produced by peeling a log in a continuous, unbroken sheet, revealing broad, bold grain patterns ideal for large surfaces like plywood. Sliced cut veneer involves slicing a log into thin sheets, showcasing more detailed, natural wood grain variations preferred for fine furniture and cabinetry. Choosing between rotary and sliced cuts depends on the desired aesthetic and application, with rotary offering bold patterns and sliced providing refined textures.

Table of Comparison

| Feature | Rotary Cut | Sliced Cut |

|---|---|---|

| Definition | Log is peeled in a continuous veneer sheet. | Log is sliced into thin, flat veneer sheets. |

| Grain Pattern | Broad, wild, and circular grain appearance. | Tight, straight, and consistent grain lines. |

| Yield | Higher veneer yield per log. | Lower yield due to slicing method. |

| Surface Quality | Less uniform surface texture. | Smoother and more refined surface. |

| Common Uses | Furniture backs, plywood core layers. | High-end furniture, decorative veneers. |

| Cost | More economical due to higher output. | Higher cost from labor-intensive process. |

Overview of Rotary Cut and Sliced Cut Techniques

Rotary cut involves peeling a log in a continuous, spiral motion, producing wide, veneer sheets with a bold, natural grain pattern ideal for plywood manufacturing. Sliced cut, also known as flitch slicing, slices the log into thin sheets using a straight blade, revealing a more refined and consistent grain pattern suitable for high-quality furniture veneers. These techniques differ in grain appearance, surface texture, and application, impacting the aesthetic and structural properties of wood products.

Key Differences Between Rotary Cut and Sliced Cut

Rotary cut wood is produced by peeling the log in a continuous, cylindrical manner, resulting in broad, less uniform grain patterns predominantly used for plywood veneers. Sliced cut wood involves slicing the log into sheets, creating more uniform and detailed grain patterns favored in high-quality furniture veneers. The key differences lie in grain appearance, production method, and typical application, with rotary cut emphasizing economy and coverage while sliced cut prioritizes aesthetic detail and texture.

Manufacturing Process: Rotary Cut Explained

Rotary cut wood veneer is produced by mounting a log centrally on a lathe and peeling it in a continuous, spiral motion, yielding wide sheets with a distinctive grain pattern. This method extracts maximum veneer from the log, making it highly efficient and cost-effective compared to other cuts. The consistent thickness and broad coverage of rotary cut veneers are ideal for applications requiring large-scale wood paneling.

Manufacturing Process: Sliced Cut Explained

Sliced cut wood veneers are produced by slicing thin sheets from a log using a large, flat bladed machine, revealing the natural grain patterns closely resembling solid wood. This manufacturing process involves cutting tangentially along the log's growth rings, which preserves the wood's surface texture and enhances visual appeal. The technique offers more uniform thickness and is widely used for aesthetic applications such as furniture and cabinetry.

Applications Best Suited for Rotary Cut Wood

Rotary cut wood excels in applications requiring large, continuous veneer sheets, such as plywood production and furniture paneling, due to its ability to maximize wood yield from logs. This cutting method is ideal for covering extensive surfaces and creating consistent grain patterns on flat panels used in cabinetry and architectural millwork. Its efficiency in producing broad, uniform veneers makes it less suitable for fine woodworking or decorative finishes where precise grain appearance is critical.

Applications Best Suited for Sliced Cut Wood

Sliced cut wood is best suited for applications requiring broad, flat surfaces with consistent grain patterns, such as cabinetry, furniture veneers, and paneling. This method produces wood sheets with a uniform appearance, ideal for decorative purposes where visual consistency enhances aesthetic appeal. The enhanced stability and reduced warping of sliced cut veneers make them preferable for high-quality interior finishes.

Visual and Structural Differences in Veneer Appearance

Rotary cut veneer features broad, bold grain patterns with a more pronounced, circular appearance due to the log being peeled in a continuous rotation, producing a less uniform texture. Sliced cut veneer, on the other hand, displays straighter, more refined grain lines and consistent patterns because it is sliced flat from the log, highlighting the wood's natural growth rings. Structurally, rotary cuts tend to be thinner and more flexible, ideal for covering large surfaces, while sliced cuts often have a thicker, denser feel, emphasizing fine detail and visual elegance.

Cost and Efficiency Comparison

Rotary cut wood involves peeling a log in a continuous veneer sheet, making it highly cost-effective and efficient for producing large quantities with minimal waste. Sliced cut wood, created by slicing logs into thinner sheets, results in more intricate grain patterns but incurs higher costs due to increased labor and material waste. Manufacturing processes favor rotary cuts for bulk applications, while sliced cuts suit projects demanding premium aesthetics despite the added expense.

Environmental Impact of Each Cutting Method

Rotary cut wood, produced by peeling the log in a continuous veneer, usually generates more waste and consumes more energy due to its less precise method, impacting deforestation rates adversely. Sliced cut wood, created by slicing thin sheets from the log, tends to produce less waste and uses less energy, leading to a reduced carbon footprint and promoting more sustainable forestry practices. Selecting sliced cut over rotary cut can significantly contribute to lowering environmental degradation linked to wood processing.

Choosing the Right Cut for Your Wood Product

Rotary cut veneer is created by peeling a log in a continuous, spiral fashion, producing broad sheets with a bold, varied grain ideal for plywood and decorative surfaces. Sliced cut veneer, on the other hand, is produced by slicing the log, resulting in a more uniform, flat grain pattern preferred for fine furniture and cabinetry. Selecting the right cut depends on the desired aesthetic, application durability, and grain consistency, with rotary cuts favored for large panels and sliced cuts for detailed, elegant finishes.

Rotary Cut vs Sliced Cut Infographic

materialdif.com

materialdif.com