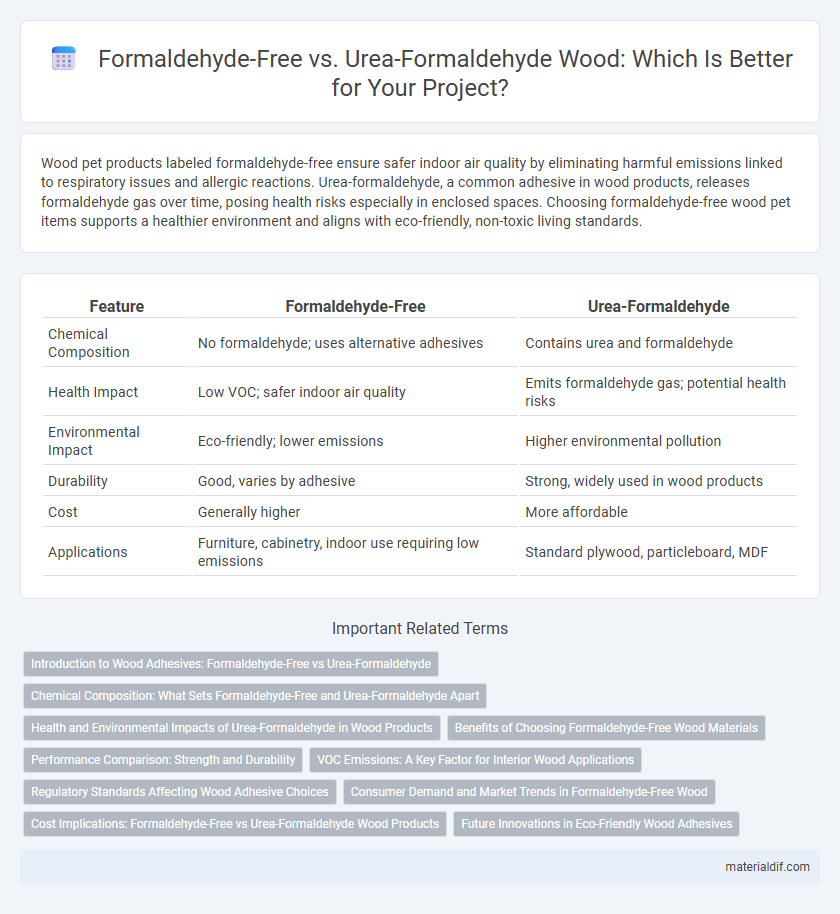

Wood pet products labeled formaldehyde-free ensure safer indoor air quality by eliminating harmful emissions linked to respiratory issues and allergic reactions. Urea-formaldehyde, a common adhesive in wood products, releases formaldehyde gas over time, posing health risks especially in enclosed spaces. Choosing formaldehyde-free wood pet items supports a healthier environment and aligns with eco-friendly, non-toxic living standards.

Table of Comparison

| Feature | Formaldehyde-Free | Urea-Formaldehyde |

|---|---|---|

| Chemical Composition | No formaldehyde; uses alternative adhesives | Contains urea and formaldehyde |

| Health Impact | Low VOC; safer indoor air quality | Emits formaldehyde gas; potential health risks |

| Environmental Impact | Eco-friendly; lower emissions | Higher environmental pollution |

| Durability | Good, varies by adhesive | Strong, widely used in wood products |

| Cost | Generally higher | More affordable |

| Applications | Furniture, cabinetry, indoor use requiring low emissions | Standard plywood, particleboard, MDF |

Introduction to Wood Adhesives: Formaldehyde-Free vs Urea-Formaldehyde

Wood adhesives play a critical role in the durability and safety of wood products, with formaldehyde-free options gaining preference due to their low emissions and environmental benefits. Urea-formaldehyde adhesives, commonly used in plywood and particleboard, provide strong bonding but release formaldehyde gas, a known irritant and potential carcinogen. Innovations in formaldehyde-free adhesives utilize bio-based and synthetic compounds, offering sustainable alternatives without compromising bond strength or product performance.

Chemical Composition: What Sets Formaldehyde-Free and Urea-Formaldehyde Apart

Formaldehyde-free wood products avoid the use of formaldehyde-based resins, relying instead on natural or alternative synthetic adhesives that emit no harmful formaldehyde gas. Urea-formaldehyde, a widely used resin in wood composites, is chemically synthesized from urea and formaldehyde, which can release formaldehyde emissions over time. The primary chemical distinction lies in the presence or absence of formaldehyde monomers, impacting indoor air quality and regulatory standards for wood materials.

Health and Environmental Impacts of Urea-Formaldehyde in Wood Products

Urea-formaldehyde resins, commonly used in wood products, release formaldehyde gas that can contribute to indoor air pollution and respiratory issues, posing health risks for sensitive individuals. Formaldehyde-free wood products eliminate these emissions, significantly reducing exposure to carcinogenic compounds and improving indoor air quality. Environmentally, formaldehyde-free alternatives minimize the release of volatile organic compounds (VOCs), supporting sustainable manufacturing practices and reducing ecological toxicity.

Benefits of Choosing Formaldehyde-Free Wood Materials

Formaldehyde-free wood materials significantly reduce indoor air pollution by eliminating harmful volatile organic compounds (VOCs) commonly released by urea-formaldehyde adhesives. These wood products enhance indoor air quality and contribute to healthier living environments by minimizing risks associated with respiratory issues and allergic reactions. Choosing formaldehyde-free wood also supports sustainable building practices by meeting stringent environmental standards such as LEED certification and CARB compliance.

Performance Comparison: Strength and Durability

Formaldehyde-free wood adhesives exhibit superior durability by eliminating the risk of toxic emissions, while maintaining comparable or enhanced bonding strength compared to urea-formaldehyde adhesives. Urea-formaldehyde, traditionally favored for its strong initial adhesion and fast curing, tends to degrade under high moisture conditions, leading to reduced long-term performance. Advanced formaldehyde-free alternatives utilize innovative resin technologies that provide improved moisture resistance and structural integrity, making them increasingly suitable for high-demand woodworking applications.

VOC Emissions: A Key Factor for Interior Wood Applications

Formaldehyde-free wood products significantly reduce volatile organic compound (VOC) emissions compared to urea-formaldehyde (UF) adhesives, enhancing indoor air quality and health safety in interior applications. Urea-formaldehyde resins, commonly used in plywood and particleboard, can release formaldehyde gas over time, posing respiratory risks and contributing to indoor pollution. Choosing formaldehyde-free materials aligns with stringent emission standards like CARB Phase 2 and LEED certification, ensuring safer living environments and compliance with environmental regulations.

Regulatory Standards Affecting Wood Adhesive Choices

Regulatory standards such as California's Air Resources Board (CARB) Phase 2 and the EPA's TSCA Title VI limit formaldehyde emissions from wood adhesives, driving manufacturers to prefer formaldehyde-free alternatives. Urea-formaldehyde adhesives, despite their strong bonding properties and cost-effectiveness, often exceed these emission thresholds, necessitating careful compliance to avoid penalties. Formaldehyde-free adhesives, including soy-based and MDI (methylene diphenyl diisocyanate) options, meet stringent VOC regulations and support sustainable wood product certification under LEED and FSC standards.

Consumer Demand and Market Trends in Formaldehyde-Free Wood

Consumer demand for formaldehyde-free wood has surged due to increasing health concerns linked to indoor air quality and toxic emissions from traditional urea-formaldehyde resins. Market trends show a significant shift toward environmentally friendly, non-toxic adhesives driven by stricter regulatory standards and growing awareness of sustainable building materials. Leading manufacturers are responding by developing innovative, green-certified formaldehyde-free wood products, capturing a larger share of the eco-conscious consumer segment.

Cost Implications: Formaldehyde-Free vs Urea-Formaldehyde Wood Products

Formaldehyde-free wood products generally incur higher manufacturing costs due to the use of alternative adhesives and stricter environmental regulations, driving up retail prices. Urea-formaldehyde wood products remain more affordable because of their widespread use, lower raw material costs, and established production processes. Choosing between the two depends on balancing budget constraints with health and environmental considerations.

Future Innovations in Eco-Friendly Wood Adhesives

Future innovations in eco-friendly wood adhesives emphasize the development of formaldehyde-free alternatives that significantly reduce indoor air pollution and health risks associated with urea-formaldehyde resins. Advances in bio-based adhesives derived from lignin, tannins, and soy proteins are gaining traction due to their renewable origin and strong bonding properties, promising enhanced sustainability in wood product manufacturing. Research in nanotechnology and enzyme-catalyzed curing processes aims to improve adhesive durability and performance while maintaining zero formaldehyde emissions, setting new standards for environmentally responsible wood composites.

Formaldehyde-Free vs Urea-Formaldehyde Infographic

materialdif.com

materialdif.com