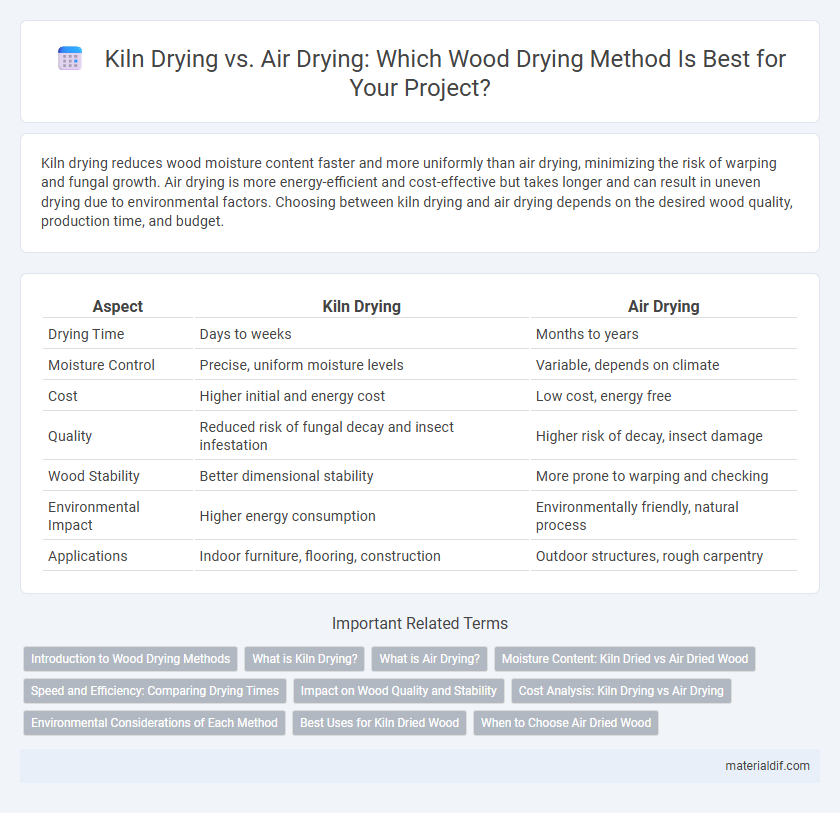

Kiln drying reduces wood moisture content faster and more uniformly than air drying, minimizing the risk of warping and fungal growth. Air drying is more energy-efficient and cost-effective but takes longer and can result in uneven drying due to environmental factors. Choosing between kiln drying and air drying depends on the desired wood quality, production time, and budget.

Table of Comparison

| Aspect | Kiln Drying | Air Drying |

|---|---|---|

| Drying Time | Days to weeks | Months to years |

| Moisture Control | Precise, uniform moisture levels | Variable, depends on climate |

| Cost | Higher initial and energy cost | Low cost, energy free |

| Quality | Reduced risk of fungal decay and insect infestation | Higher risk of decay, insect damage |

| Wood Stability | Better dimensional stability | More prone to warping and checking |

| Environmental Impact | Higher energy consumption | Environmentally friendly, natural process |

| Applications | Indoor furniture, flooring, construction | Outdoor structures, rough carpentry |

Introduction to Wood Drying Methods

Kiln drying and air drying are two primary methods used to reduce moisture content in wood, essential for preventing warping, cracking, and fungal growth. Kiln drying involves controlled, accelerated drying in a temperature and humidity-regulated chamber, ensuring consistent moisture levels and improved structural stability. Air drying relies on natural airflow and ambient conditions, which is slower and less uniform but more energy-efficient and environmentally friendly.

What is Kiln Drying?

Kiln drying is a controlled wood-drying process that uses a heated chamber to reduce moisture content rapidly and uniformly. This method enhances wood stability, strength, and resistance to decay compared to natural air drying. Kiln drying also minimizes defects such as warping and checking, making it essential for high-quality lumber production.

What is Air Drying?

Air drying is a traditional wood drying method where lumber is stacked and exposed to natural air circulation, allowing moisture content to decrease gradually. This process typically takes several months, depending on wood species, thickness, and environmental conditions, resulting in moisture levels around 12-20%. Air drying is energy-efficient and helps reduce internal stresses, but it may not achieve the low moisture content required for some woodworking applications.

Moisture Content: Kiln Dried vs Air Dried Wood

Kiln drying reduces wood moisture content to 6-8%, providing consistent and stable wood ideal for indoor use and preventing warping or fungal growth. In contrast, air-dried wood typically retains 12-20% moisture, requiring longer drying time and varying moisture levels depending on climate and wood species. Precise moisture control in kiln drying enhances wood durability and dimensional stability compared to the variable moisture content of air-dried lumber.

Speed and Efficiency: Comparing Drying Times

Kiln drying reduces moisture content in wood significantly faster, achieving optimal levels in days compared to air drying, which can take several months to over a year depending on climate. The controlled environment of a kiln accelerates the drying process while minimizing defects like warping and checking, enhancing overall efficiency. Air drying relies on natural airflow and ambient conditions, making it less predictable and slower but more energy-efficient and cost-effective.

Impact on Wood Quality and Stability

Kiln drying significantly enhances wood quality by rapidly reducing moisture content, resulting in uniform stability and minimizing the risk of warping, splitting, and fungal growth compared to air drying. Air drying, while slower, allows for natural moisture evaporation that preserves wood's natural oils but can lead to uneven drying and increased susceptibility to defects. The controlled environment of kiln drying ensures greater dimensional stability, making it ideal for high-quality woodworking and construction applications.

Cost Analysis: Kiln Drying vs Air Drying

Kiln drying incurs higher initial costs due to energy consumption and equipment investment but offers faster drying times, reducing storage and handling expenses. Air drying requires minimal energy costs but often extends drying duration, leading to potential increased labor and inventory holding costs. Evaluating total expenses reveals kiln drying is more cost-effective for high-volume production, while air drying suits low-budget or less time-sensitive projects.

Environmental Considerations of Each Method

Kiln drying uses controlled heat and ventilation, which speeds up moisture removal but consumes significant energy and may produce greenhouse gas emissions depending on the power source. Air drying relies on natural airflow and ambient conditions, resulting in minimal energy use and a smaller carbon footprint, though it requires more time and space. Sustainable forestry practices and renewable energy integration can mitigate environmental impacts for both drying methods.

Best Uses for Kiln Dried Wood

Kiln dried wood is ideal for interior applications such as furniture, cabinetry, and flooring due to its controlled moisture content, which minimizes warping, shrinking, and insect infestation. The process ensures consistent dimensional stability, making it suitable for precision woodworking and construction projects requiring tight tolerances. Kiln drying also accelerates seasoning compared to air drying, reducing the risk of mold and fungi while allowing faster project completion times.

When to Choose Air Dried Wood

Air dried wood is ideal for projects where slight moisture content variation is acceptable, offering a more natural drying process that preserves wood's inherent strength and reduces energy costs. It suits outdoor applications, rustic furniture, and construction where wood is exposed to environmental moisture changes. Choose air dried wood when cost efficiency and minimal warping are prioritized over rapid drying and precise moisture control typical of kiln-dried lumber.

Kiln Drying vs Air Drying Infographic

materialdif.com

materialdif.com