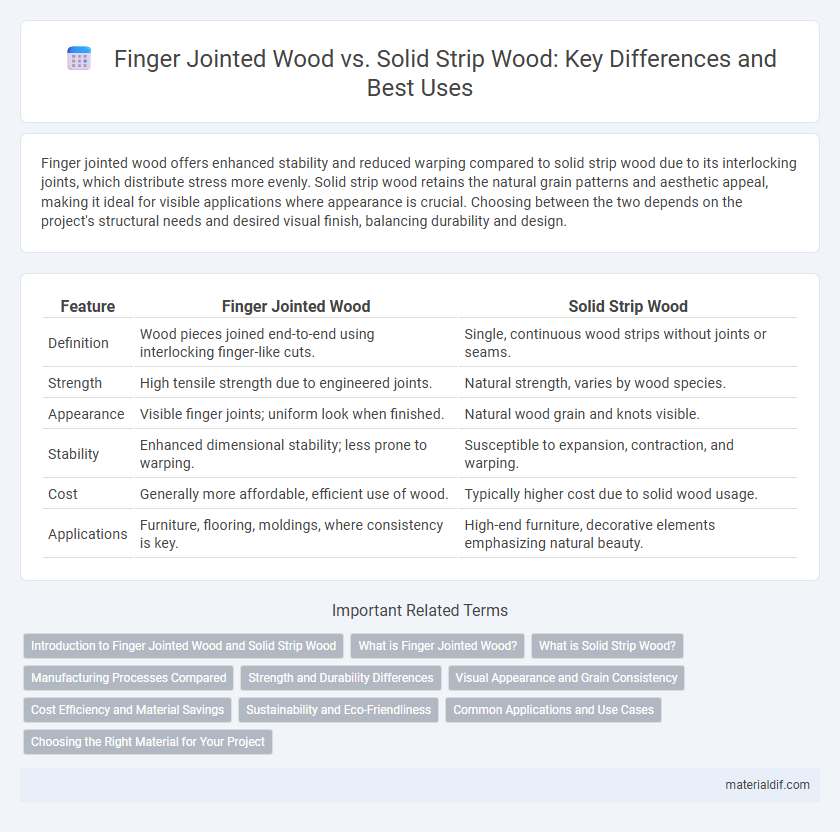

Finger jointed wood offers enhanced stability and reduced warping compared to solid strip wood due to its interlocking joints, which distribute stress more evenly. Solid strip wood retains the natural grain patterns and aesthetic appeal, making it ideal for visible applications where appearance is crucial. Choosing between the two depends on the project's structural needs and desired visual finish, balancing durability and design.

Table of Comparison

| Feature | Finger Jointed Wood | Solid Strip Wood |

|---|---|---|

| Definition | Wood pieces joined end-to-end using interlocking finger-like cuts. | Single, continuous wood strips without joints or seams. |

| Strength | High tensile strength due to engineered joints. | Natural strength, varies by wood species. |

| Appearance | Visible finger joints; uniform look when finished. | Natural wood grain and knots visible. |

| Stability | Enhanced dimensional stability; less prone to warping. | Susceptible to expansion, contraction, and warping. |

| Cost | Generally more affordable, efficient use of wood. | Typically higher cost due to solid wood usage. |

| Applications | Furniture, flooring, moldings, where consistency is key. | High-end furniture, decorative elements emphasizing natural beauty. |

Introduction to Finger Jointed Wood and Solid Strip Wood

Finger jointed wood consists of short wood pieces joined end-to-end with interlocking fingers, enhancing length and reducing waste while maintaining structural integrity. Solid strip wood is made from single, continuous strips of wood, offering natural strength and uniform grain patterns ideal for visible applications. Finger jointed wood is often favored for cost efficiency and stability, whereas solid strip wood is preferred for aesthetics and durability.

What is Finger Jointed Wood?

Finger jointed wood is engineered by joining short wood pieces end-to-end using interlocking finger-like cuts, creating a strong, stable panel that maximizes material usage and minimizes waste. This method enhances dimensional stability and reduces the likelihood of warping compared to solid strip wood, which is cut from a single continuous piece. Commonly used in furniture, molding, and flooring, finger jointed wood provides cost-effective versatility while maintaining aesthetic quality.

What is Solid Strip Wood?

Solid strip wood consists of narrow pieces of lumber glued together to form a longer, wider board, offering enhanced stability and reduced warping compared to natural solid wood planks. This engineered wood product is commonly used in cabinetry, furniture, and flooring due to its consistent grain pattern and structural strength. Unlike finger jointed wood, which uses interlocking end joints, solid strip wood maintains continuous grain along each strip for improved aesthetic appeal and durability.

Manufacturing Processes Compared

Finger jointed wood is manufactured by joining short wood pieces using interlocking finger-like cuts glued together to form long, stable boards, optimizing material usage and reducing waste. Solid strip wood, by contrast, is milled directly from single continuous pieces of timber, preserving natural grain but often resulting in higher material costs and greater susceptibility to warping. The finger jointing process allows for more consistent dimensions and better strength characteristics, while solid strip wood retains traditional aesthetics and structural integrity inherent to full timber sections.

Strength and Durability Differences

Finger jointed wood consists of short wood pieces joined together with interlocking fingers, providing consistent strength and reducing waste, while solid strip wood is made from continuous single pieces, offering natural grain integrity and potentially higher load-bearing capacity. Finger jointed wood is engineered for stability and uniformity, resisting warping and splitting better in variable conditions, whereas solid strip wood may be more prone to defects like knots and cracks that affect durability. For applications requiring dimensional stability and efficient use of materials, finger jointed wood offers superior performance, whereas solid strip wood excels where maximum natural strength and aesthetics are critical.

Visual Appearance and Grain Consistency

Finger jointed wood offers a uniform grain appearance by joining shorter pieces with interlocking cuts, minimizing natural wood defects and providing a consistent look ideal for modern furniture and flooring. Solid strip wood features continuous grain patterns with natural variations, showcasing authentic wood aesthetics that appeal to traditional woodworking projects seeking unique character. Finger jointed wood ensures greater grain consistency, while solid strip wood emphasizes distinct visual appeal through natural grain diversity.

Cost Efficiency and Material Savings

Finger jointed wood offers greater cost efficiency and material savings compared to solid strip wood by utilizing shorter wood pieces joined together to create longer lengths, reducing waste and maximizing resource use. This engineered wood product typically costs less due to the ability to use lower-grade wood segments while maintaining structural integrity. Solid strip wood, in contrast, requires longer, defect-free lumber, often resulting in higher material costs and less efficient use of raw timber.

Sustainability and Eco-Friendliness

Finger jointed wood maximizes material use by bonding shorter wood pieces together, reducing waste and promoting sustainable forestry practices. Solid strip wood, sourced from single timber pieces, often results in higher material consumption and increased environmental impact. Sustainable construction favors finger jointed wood due to its efficient resource utilization and lower carbon footprint.

Common Applications and Use Cases

Finger jointed wood is commonly used in cabinetry, furniture making, and molding due to its enhanced stability and efficient use of smaller wood pieces, making it ideal for long, straight components. Solid strip wood is favored in flooring, joinery, and decorative paneling where structural integrity and natural wood appearance are crucial. Both materials serve distinct roles, with finger jointed wood excelling in cost-effective, dimensionally stable applications, while solid strip wood is preferred for strength and aesthetic purposes.

Choosing the Right Material for Your Project

Finger jointed wood offers enhanced stability and cost-effectiveness by combining shorter wood segments with interlocking joints, making it ideal for larger projects requiring uniformity. Solid strip wood provides natural strength and aesthetic appeal with continuous grain, preferred for visible surfaces and smaller-scale applications. Selecting between these materials depends on project size, structural demands, and desired visual characteristics.

Finger Jointed Wood vs Solid Strip Wood Infographic

materialdif.com

materialdif.com