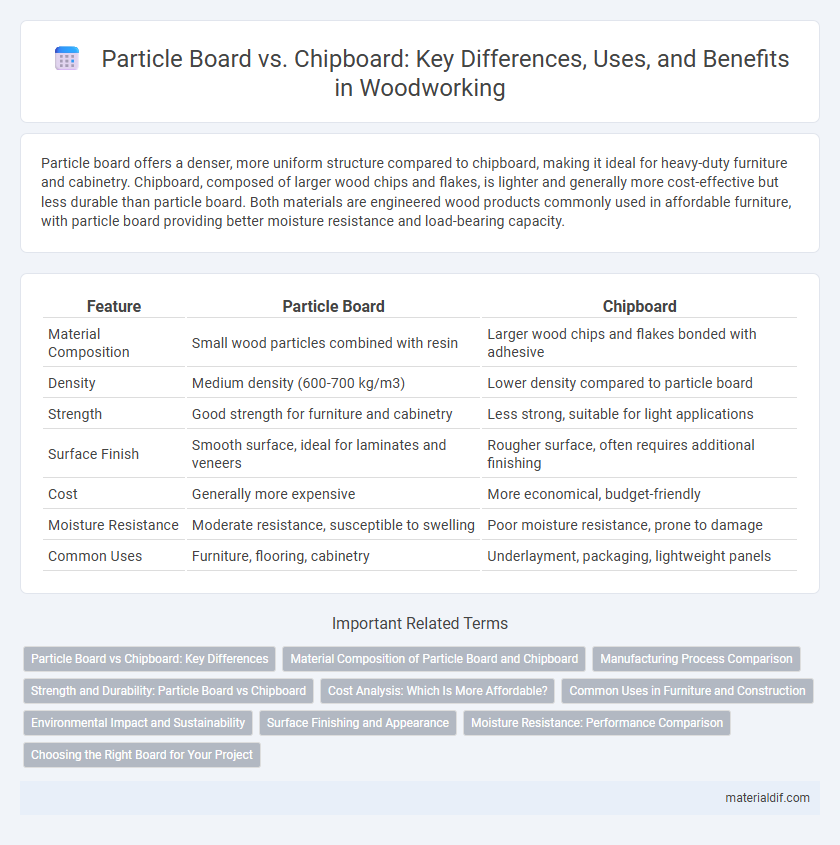

Particle board offers a denser, more uniform structure compared to chipboard, making it ideal for heavy-duty furniture and cabinetry. Chipboard, composed of larger wood chips and flakes, is lighter and generally more cost-effective but less durable than particle board. Both materials are engineered wood products commonly used in affordable furniture, with particle board providing better moisture resistance and load-bearing capacity.

Table of Comparison

| Feature | Particle Board | Chipboard |

|---|---|---|

| Material Composition | Small wood particles combined with resin | Larger wood chips and flakes bonded with adhesive |

| Density | Medium density (600-700 kg/m3) | Lower density compared to particle board |

| Strength | Good strength for furniture and cabinetry | Less strong, suitable for light applications |

| Surface Finish | Smooth surface, ideal for laminates and veneers | Rougher surface, often requires additional finishing |

| Cost | Generally more expensive | More economical, budget-friendly |

| Moisture Resistance | Moderate resistance, susceptible to swelling | Poor moisture resistance, prone to damage |

| Common Uses | Furniture, flooring, cabinetry | Underlayment, packaging, lightweight panels |

Particle Board vs Chipboard: Key Differences

Particle board is made from wood chips, sawmill shavings, and a synthetic resin or other binders, creating a dense and uniform panel, while chipboard typically uses larger wood chips and flakes, resulting in a rougher texture and less strength. Particle board offers better moisture resistance and smoother surface finish compared to chipboard, making it more suitable for furniture and interior applications. Chipboard is generally cheaper but less durable, often used for temporary or lightweight constructions.

Material Composition of Particle Board and Chipboard

Particle board consists of wood particles, such as wood chips, sawmill shavings, and sawdust, bonded together with a synthetic resin or binder under heat and pressure. Chipboard, often considered synonymous with particle board, primarily uses larger wood chips and flakes in its composition, resulting in a coarser texture. The distinction lies in the size and refinement of the wood particles, impacting the density and strength of the final product.

Manufacturing Process Comparison

Particle board and chipboard differ primarily in their manufacturing processes; particle board is created by compressing wood chips, sawdust, and resin under high pressure and heat, resulting in a dense, uniform panel. Chipboard, also known as low-density fiberboard, is manufactured using larger wood particles bonded with adhesive, typically through a dry process, producing a board with a rougher texture and lower density. These distinct fabrication methods influence the strength, moisture resistance, and application of each material in furniture and construction industries.

Strength and Durability: Particle Board vs Chipboard

Particle board features a denser composition with resin and fine wood particles, resulting in higher strength and improved resistance to warping compared to chipboard. Chipboard, manufactured from larger wood chips and a lower resin content, tends to be less durable and more susceptible to moisture damage and structural weakening over time. For applications requiring long-term stability and load-bearing capacity, particle board is generally the superior choice due to its enhanced mechanical properties.

Cost Analysis: Which Is More Affordable?

Particle board is generally more affordable than chipboard due to its lower manufacturing costs and the use of smaller wood particles combined with adhesive resins. Chipboard's denser composition and higher quality wood chips result in increased production expenses, leading to a higher market price. For budget-conscious projects requiring expansive surface coverage, particle board offers a cost-effective solution without significantly compromising basic structural integrity.

Common Uses in Furniture and Construction

Particle board is extensively used in affordable furniture manufacturing, such as cabinets, shelves, and flat-pack furniture, due to its smooth surface ideal for veneers and laminates. Chipboard finds its common applications in construction for subflooring, underlayment, and interior wall panels, valued for its strength and density. Both materials serve as cost-effective alternatives to solid wood, with particle board favored for finished surfaces and chipboard preferred where structural support is essential.

Environmental Impact and Sustainability

Particle board and chipboard both utilize wood waste, promoting resource efficiency and reducing deforestation. Particle board typically contains more adhesives with formaldehyde emissions, while eco-friendly chipboard variants use low-emission binders, enhancing indoor air quality. Recycling and biodegradability rates favor chipboard, making it a more sustainable option in environmentally-conscious cabinetry and furniture production.

Surface Finishing and Appearance

Particle board typically features a rougher surface that often requires a veneer or laminate finish to enhance its appearance and protect against moisture. Chipboard, known for its denser composition, generally offers a smoother surface that can be painted or laminated directly without extensive preparation. Both materials can achieve a visually appealing finish, but chipboard tends to provide a more uniform and polished look due to its finer texture and better surface integrity.

Moisture Resistance: Performance Comparison

Particle board typically offers better moisture resistance compared to chipboard due to its denser composition and the use of synthetic resins that enhance water repellency. Chipboard, made from larger wood chips and less tightly bound materials, tends to absorb moisture more easily, leading to swelling and reduced structural integrity. In applications requiring exposure to humidity or occasional water contact, particle board is preferred for its superior durability and resistance to moisture-related damage.

Choosing the Right Board for Your Project

Particle board offers a smoother surface ideal for laminates and veneers, making it suitable for furniture and cabinetry, while chipboard is more affordable and often used in structural applications like shelving and underlayment. Both materials are manufactured from wood chips and resin, but particle board typically has finer particles that provide enhanced strength and durability. Selecting the right board depends on your project's requirements for load-bearing capacity, finish quality, and budget constraints.

Particle Board vs Chipboard Infographic

materialdif.com

materialdif.com