MDF core offers superior smoothness and strength compared to particleboard core, making it ideal for fine finishes and intricate designs. Particleboard core is generally more affordable but less durable, prone to swelling and damage when exposed to moisture. Choosing between MDF and particleboard cores depends on the application's need for durability, surface quality, and budget constraints.

Table of Comparison

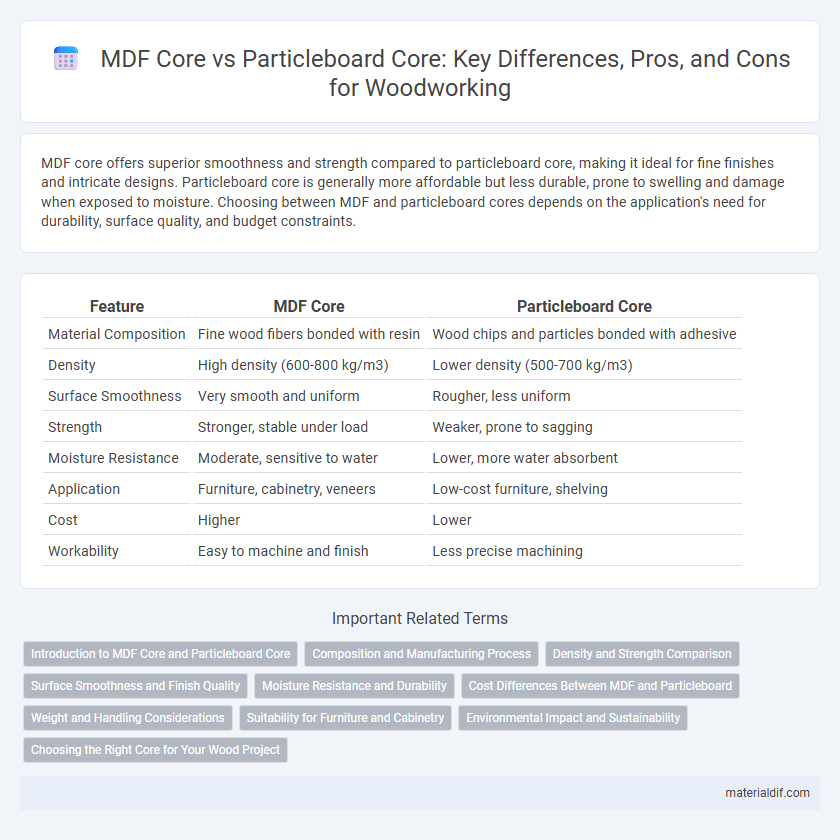

| Feature | MDF Core | Particleboard Core |

|---|---|---|

| Material Composition | Fine wood fibers bonded with resin | Wood chips and particles bonded with adhesive |

| Density | High density (600-800 kg/m3) | Lower density (500-700 kg/m3) |

| Surface Smoothness | Very smooth and uniform | Rougher, less uniform |

| Strength | Stronger, stable under load | Weaker, prone to sagging |

| Moisture Resistance | Moderate, sensitive to water | Lower, more water absorbent |

| Application | Furniture, cabinetry, veneers | Low-cost furniture, shelving |

| Cost | Higher | Lower |

| Workability | Easy to machine and finish | Less precise machining |

Introduction to MDF Core and Particleboard Core

MDF core consists of finely ground wood fibers bonded with resin under high pressure, producing a dense, smooth, and uniform surface ideal for painting and laminating. Particleboard core is made from coarser wood particles and adhesive, resulting in a less dense and more porous material commonly used in budget-friendly furniture and cabinetry. Both cores serve as foundational layers in engineered wood panels, with MDF offering enhanced strength and finish quality compared to particleboard.

Composition and Manufacturing Process

MDF core consists of finely ground wood fibers bonded with resin under high heat and pressure, resulting in a dense, uniform panel ideal for smooth finishes. Particleboard core is made from larger wood particles and chips mixed with adhesive, pressed into sheets that are less dense and offer lower moisture resistance compared to MDF. The manufacturing process of MDF core involves fiber refining and extensive pressing, while particleboard core production emphasizes particle size sorting and less intense compression.

Density and Strength Comparison

MDF core panels exhibit higher density, typically ranging from 600 to 800 kg/m3, resulting in superior strength and smoother finishing compared to particleboard cores, which have lower density around 500 to 700 kg/m3. The uniform composition of MDF enhances load-bearing capacity and resistance to warping, making it ideal for precise machining and cabinetry. Particleboard cores, being less dense, offer moderate strength suitable for budget applications but are more prone to damage under heavy stress.

Surface Smoothness and Finish Quality

MDF core offers superior surface smoothness compared to particleboard core, providing an even and dense substrate ideal for high-quality finishes such as veneers and paints. The fine, uniform texture of MDF minimizes surface imperfections, resulting in a flawless appearance and easier application of coatings. Particleboard core, with its coarser and uneven texture, may cause challenges in achieving a smooth finish, often requiring additional preparation or thicker layers of surface material.

Moisture Resistance and Durability

MDF core offers superior moisture resistance compared to particleboard core due to its dense, uniform composition, reducing the risk of swelling and warping in humid environments. Particleboard core, while more affordable, tends to absorb moisture more readily, leading to decreased durability over time. For applications requiring enhanced longevity and resilience against moisture, MDF core is the preferred choice.

Cost Differences Between MDF and Particleboard

MDF core typically costs more than particleboard core due to its denser composition and smoother finish, which provide superior durability and surface uniformity for cabinetry and furniture applications. Particleboard core is generally less expensive because it uses larger wood particles bonded with resin, resulting in lower material and manufacturing costs but reduced strength and moisture resistance. Choosing between MDF and particleboard cores depends largely on budget constraints and the intended use environment, where MDF offers a higher upfront cost but greater long-term value in terms of quality and finish.

Weight and Handling Considerations

MDF core panels typically weigh more than particleboard core panels due to the density of medium-density fiberboard, affecting ease of handling and transport costs. Particleboard core is lighter, making it preferable for applications requiring frequent movement or reduced structural load. Choosing between MDF and particleboard cores depends on balancing weight considerations with durability and surface finish requirements in woodworking projects.

Suitability for Furniture and Cabinetry

MDF core offers a smooth, dense surface ideal for detailed painting and veneer finishing, making it highly suitable for fine furniture and cabinetry requiring precision and durability. Particleboard core, while more cost-effective, is less dense and prone to moisture damage, often limiting its use to budget-friendly or temporary cabinetry solutions. Both materials provide structural support, but MDF core's uniformity and resistance to warping make it the preferred choice for high-quality woodworking projects.

Environmental Impact and Sustainability

MDF core is generally more sustainable than particleboard core due to its higher density and use of fine wood fibers, which often come from recycled wood waste, reducing deforestation pressures. Particleboard core, while also utilizing wood residues, tends to have lower durability and can release more formaldehyde-based resins, impacting indoor air quality and environmental health. Choosing MDF core supports better resource efficiency and contributes to lower carbon footprints in furniture and construction applications.

Choosing the Right Core for Your Wood Project

MDF core offers superior smoothness and consistent density, making it ideal for fine finishes and intricate detailing in wood projects. Particleboard core provides cost-effective strength and is suitable for furniture or cabinetry where weight and budget are priorities. Selecting the right core depends on the project's durability requirements and desired surface quality to ensure longevity and aesthetic appeal.

MDF Core vs Particleboard Core Infographic

materialdif.com

materialdif.com