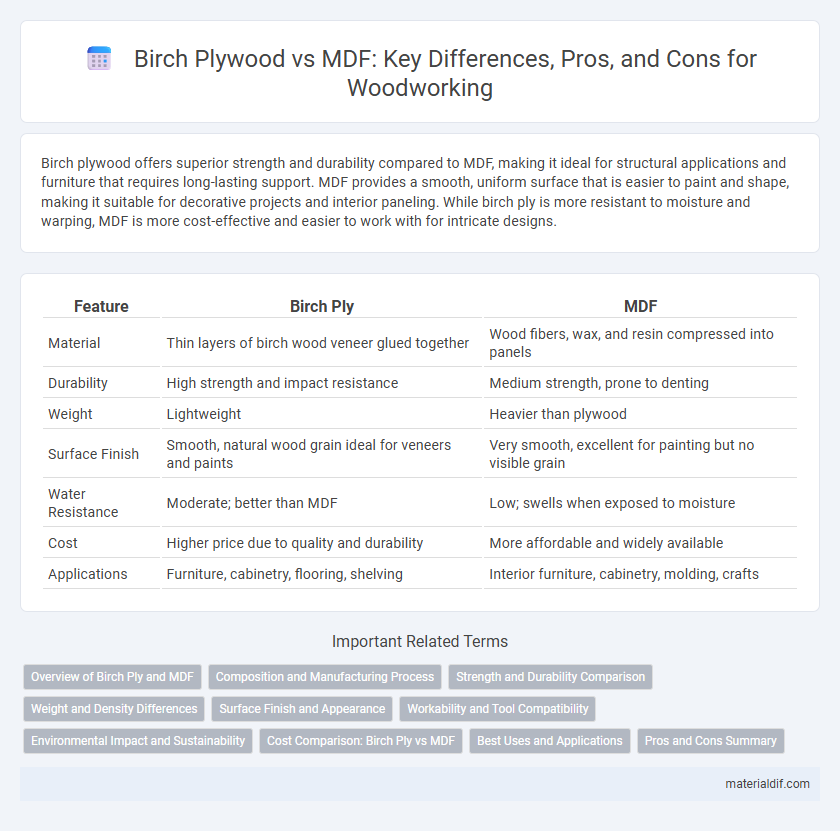

Birch plywood offers superior strength and durability compared to MDF, making it ideal for structural applications and furniture that requires long-lasting support. MDF provides a smooth, uniform surface that is easier to paint and shape, making it suitable for decorative projects and interior paneling. While birch ply is more resistant to moisture and warping, MDF is more cost-effective and easier to work with for intricate designs.

Table of Comparison

| Feature | Birch Ply | MDF |

|---|---|---|

| Material | Thin layers of birch wood veneer glued together | Wood fibers, wax, and resin compressed into panels |

| Durability | High strength and impact resistance | Medium strength, prone to denting |

| Weight | Lightweight | Heavier than plywood |

| Surface Finish | Smooth, natural wood grain ideal for veneers and paints | Very smooth, excellent for painting but no visible grain |

| Water Resistance | Moderate; better than MDF | Low; swells when exposed to moisture |

| Cost | Higher price due to quality and durability | More affordable and widely available |

| Applications | Furniture, cabinetry, flooring, shelving | Interior furniture, cabinetry, molding, crafts |

Overview of Birch Ply and MDF

Birch plywood is made from thin layers of birch veneer, providing high strength, durability, and a smooth finish ideal for furniture and cabinetry. MDF (Medium-Density Fiberboard) consists of wood fibers combined with resin under heat and pressure, offering a uniform, dense surface perfect for painting and intricate cutting. Birch plywood has superior moisture resistance and load-bearing capacity compared to MDF, which is more prone to swelling but more cost-effective.

Composition and Manufacturing Process

Birch plywood consists of thin layers of birch veneer glued together with the grain of each layer perpendicular to the previous one, enhancing strength and durability through a cross-grain construction. MDF (medium-density fiberboard) is made by breaking down hardwood and softwood fibers into small particles, then combining them with wax and resin binders under heat and pressure to form a dense, uniform panel. Birch plywood's natural wood grain and layered structure provide superior bending strength, while MDF's homogenous composition allows for smooth finishes but less resistance to moisture and impact.

Strength and Durability Comparison

Birch plywood offers superior strength and durability compared to MDF due to its natural wood layers and cross-grain construction, providing higher resistance to bending and impact. MDF, made from compressed wood fibers and resin, is denser but less structurally robust, making it prone to sagging and damage under heavy loads or moisture exposure. For applications requiring long-lasting strength and stability, birch ply is the preferred choice over MDF.

Weight and Density Differences

Birch plywood features a higher density, typically around 650-700 kg/m3, making it heavier and stronger compared to MDF, which usually has a density of approximately 600-700 kg/m3 but with a more uniform composition. The weight difference impacts handling and application, with birch ply offering superior load-bearing capacity ideal for structural purposes. MDF's lighter weight and consistent density make it suitable for precision woodworking and indoor furniture where weight reduction is beneficial.

Surface Finish and Appearance

Birch plywood features a smooth, fine-grain surface with natural wood patterns that enhance its aesthetic appeal, making it ideal for visible finishes and furniture applications. MDF offers a uniformly smooth surface ideal for painting and veneer application but lacks the natural wood texture found in birch ply. The birch ply's layered construction provides durability and a premium wood finish, while MDF's engineered composition allows for easy customization but may show wear more quickly.

Workability and Tool Compatibility

Birch plywood offers superior workability with its layered construction, allowing clean cuts, easy sanding, and excellent screw-holding capacity, making it ideal for cabinetry and furniture projects. MDF, composed of fine wood fibers, provides a smooth surface ideal for painting but can generate more dust and dull tools faster due to its density and resin content. Both materials are compatible with standard woodworking tools, yet sharp carbide blades and bits are recommended to maintain tool longevity when cutting MDF.

Environmental Impact and Sustainability

Birch plywood outperforms MDF in environmental impact due to its use of natural wood veneers that are often sourced from sustainably managed forests, resulting in lower formaldehyde emissions and better biodegradability. MDF production involves significant use of resins and adhesives containing urea-formaldehyde, contributing to higher indoor air pollution and challenges in recycling. Choosing birch ply supports sustainable forestry practices and reduces exposure to harmful chemicals, making it a more eco-friendly option for wood-based materials.

Cost Comparison: Birch Ply vs MDF

Birch ply typically costs more than MDF due to its higher-quality veneer layers and superior strength, making it a preferred choice for cabinetry and furniture that demand durability. MDF, composed of compressed wood fibers, offers a budget-friendly alternative for interior applications such as shelving and decorative panels. The cost difference often ranges from 20% to 50%, with MDF favored for cost-sensitive projects and birch ply selected where structural integrity and aesthetics justify the investment.

Best Uses and Applications

Birch plywood offers superior strength and durability, making it ideal for cabinetry, furniture, and structural applications where stability and aesthetic grain patterns are essential. MDF excels in smooth, uniform surfaces suitable for painted finishes, making it perfect for interior projects like mouldings, shelving, and decorative panels. While birch plywood handles moisture better and supports heavy loads, MDF is preferred for detailed cutting and cost-effective indoor use.

Pros and Cons Summary

Birch plywood offers superior strength, durability, and aesthetic appeal with its natural wood grain, making it ideal for furniture and cabinetry, yet it tends to be more expensive and heavier than MDF. MDF provides a smooth, consistent surface perfect for painting and intricate cutting, offering affordability and ease of use but lacks the structural integrity and moisture resistance of birch plywood. Choosing between birch ply and MDF depends on the project's requirements for strength, finish quality, and budget constraints.

Birch Ply vs MDF Infographic

materialdif.com

materialdif.com