Quarter sawn wood features a distinctive grain pattern with increased stability, making it less prone to warping and offering enhanced durability compared to plain sawn wood. Plain sawn lumber displays a broader grain pattern that maximizes yield and reduces cost, but it is more susceptible to cupping and swelling. Choosing between quarter sawn and plain sawn depends on the desired aesthetic, structural stability, and budget considerations for woodworking projects.

Table of Comparison

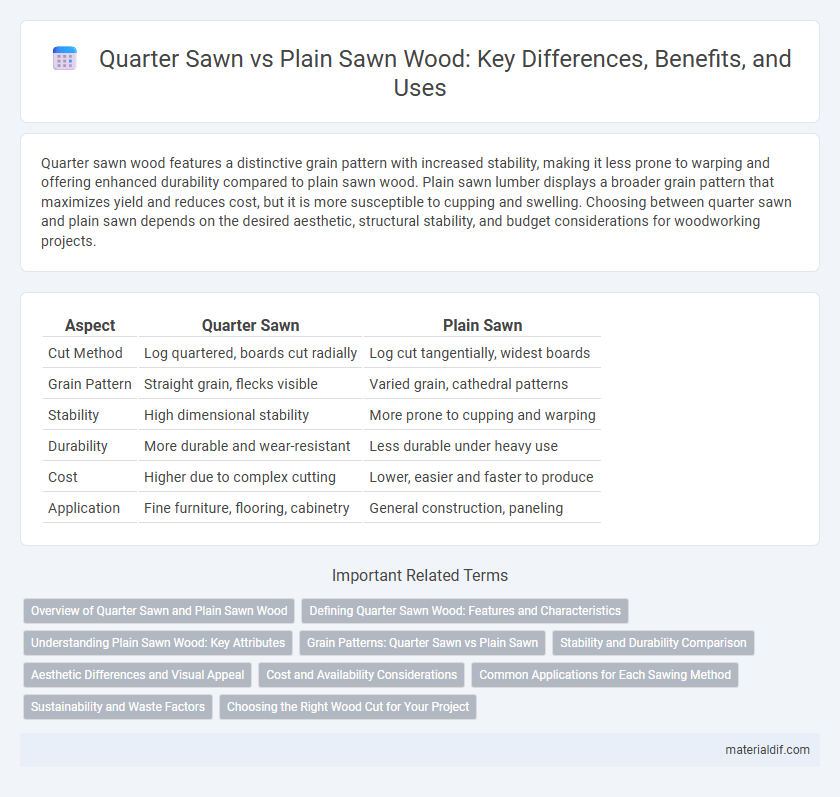

| Aspect | Quarter Sawn | Plain Sawn |

|---|---|---|

| Cut Method | Log quartered, boards cut radially | Log cut tangentially, widest boards |

| Grain Pattern | Straight grain, flecks visible | Varied grain, cathedral patterns |

| Stability | High dimensional stability | More prone to cupping and warping |

| Durability | More durable and wear-resistant | Less durable under heavy use |

| Cost | Higher due to complex cutting | Lower, easier and faster to produce |

| Application | Fine furniture, flooring, cabinetry | General construction, paneling |

Overview of Quarter Sawn and Plain Sawn Wood

Quarter sawn wood features a distinct grain pattern with straight, tight lines and increased stability, making it less prone to warping and shrinking compared to plain sawn wood. Plain sawn wood, cut tangentially to the growth rings, displays a more varied grain pattern with wider, cathedral-like curves, offering a cost-effective option with maximum yield from each log. Both methods impact the wood's appearance, structural properties, and application suitability, influencing choices in furniture, flooring, and cabinetry.

Defining Quarter Sawn Wood: Features and Characteristics

Quarter sawn wood is produced by cutting logs into quarters before sawing perpendicular to the growth rings, resulting in a distinctive grain pattern with straight, even lines and ray flecks. This method enhances stability and reduces warping and cupping compared to plain sawn wood, making it ideal for high-quality furniture and flooring. Its denser grain structure also provides a unique aesthetic, often preferred for its durability and visually striking appearance.

Understanding Plain Sawn Wood: Key Attributes

Plain sawn wood, also known as flat sawn, is characterized by its distinctive grain pattern with cathedrals and growth rings that run parallel to the board's face, maximizing yield and minimizing waste. This cutting method produces wood with greater stability in width but can exhibit more pronounced cupping and warping compared to quarter sawn. Plain sawn lumber is widely preferred for its affordability, efficient production, and attractive grain pattern, making it a common choice in furniture and flooring applications.

Grain Patterns: Quarter Sawn vs Plain Sawn

Quarter sawn wood displays straight, tight grain patterns with visible medullary rays, enhancing its stability and aesthetic appeal. Plain sawn wood features wider, cathedral or flame-shaped grain patterns that offer a more traditional and varied look but are more prone to warping. These distinct grain patterns affect both the visual texture and structural performance of lumber in woodworking projects.

Stability and Durability Comparison

Quarter sawn wood offers superior stability due to its unique radial cutting pattern, minimizing warping and cupping compared to plain sawn wood, which is more prone to dimensional changes. The tighter grain orientation in quarter sawn boards enhances durability by distributing stress more evenly and resisting wear over time. Plain sawn lumber, while more economical and yielding wider planks, generally exhibits less structural integrity under fluctuating moisture conditions.

Aesthetic Differences and Visual Appeal

Quarter sawn wood features a distinctive, straight grain pattern with visible ray flecks that create a uniform and striking appearance, often preferred for its elegant and classic aesthetic. Plain sawn wood displays a varied, wavy grain with prominent cathedral patterns, offering a more rustic and dynamic visual appeal. These aesthetic differences influence design choices, with quarter sawn wood favored for formal settings and plain sawn wood for casual or natural looks.

Cost and Availability Considerations

Quarter sawn wood typically costs more due to higher labor intensity and increased waste during milling, making it less readily available compared to plain sawn lumber. Plain sawn wood is widely produced, resulting in lower prices and greater availability in various species and sizes. When budgeting or sourcing materials, the choice between quarter sawn and plain sawn impacts both project cost and lead times significantly.

Common Applications for Each Sawing Method

Quarter sawn wood, prized for its straight grain and dimensional stability, is commonly used in high-end furniture, flooring, and musical instruments where aesthetics and durability are crucial. Plain sawn wood, characterized by its wider grain patterns and cost-effectiveness, dominates in general construction, cabinetry, and paneling applications. Each sawing method optimizes wood performance based on the specific strength, appearance, and budget requirements of the project.

Sustainability and Waste Factors

Quarter sawn wood produces minimal waste due to its efficient cutting method, optimizing usable lumber and enhancing sustainability by reducing material loss. Plain sawn wood yields more waste from irregular cuts, contributing to higher resource consumption and environmental impact. Choosing quarter sawn lumber supports sustainable forestry practices by maximizing wood utilization and minimizing ecological footprint.

Choosing the Right Wood Cut for Your Project

Quarter sawn wood offers enhanced stability and distinctive grain patterns, making it ideal for fine furniture and flooring projects requiring durability. Plain sawn wood provides a more economical option with broader grain patterns, suitable for general construction and applications where budget is a priority. Evaluating the specific requirements of your project, such as aesthetic preference, structural integrity, and cost, will guide the optimal choice between quarter sawn and plain sawn lumber.

Quarter Sawn vs Plain Sawn Infographic

materialdif.com

materialdif.com