Face veneer showcases the highest quality wood grain, providing a visually appealing and smooth surface on wood pet products. Back veneer, used on the reverse side, is typically of lower grade and serves to stabilize the structure without compromising the aesthetic appeal. The difference in veneer quality impacts both the durability and the overall visual experience of wood pet items.

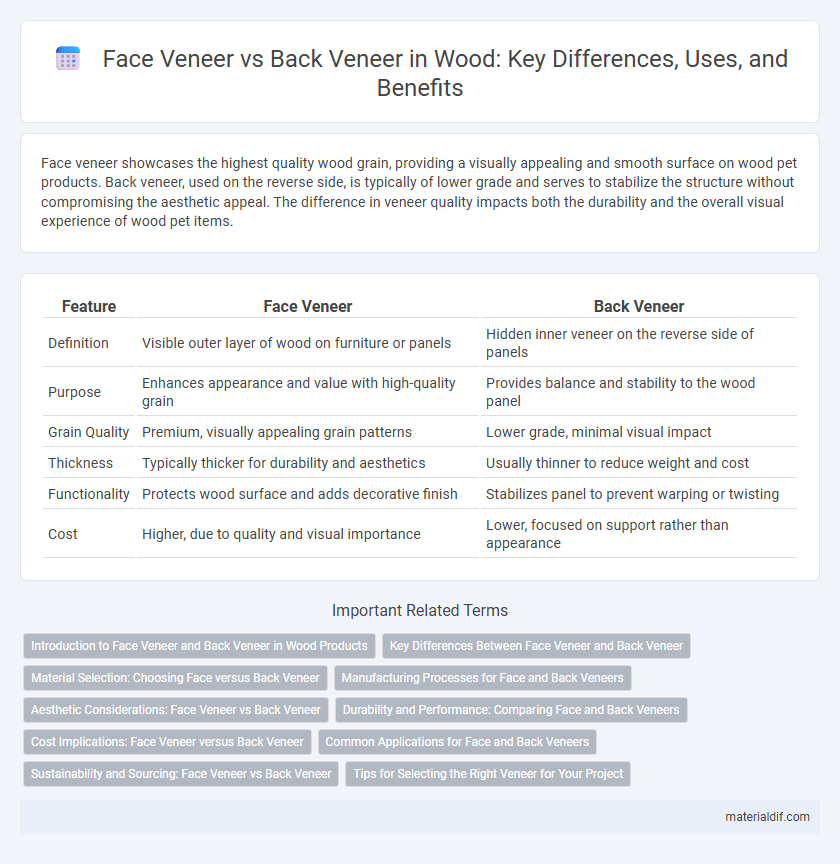

Table of Comparison

| Feature | Face Veneer | Back Veneer |

|---|---|---|

| Definition | Visible outer layer of wood on furniture or panels | Hidden inner veneer on the reverse side of panels |

| Purpose | Enhances appearance and value with high-quality grain | Provides balance and stability to the wood panel |

| Grain Quality | Premium, visually appealing grain patterns | Lower grade, minimal visual impact |

| Thickness | Typically thicker for durability and aesthetics | Usually thinner to reduce weight and cost |

| Functionality | Protects wood surface and adds decorative finish | Stabilizes panel to prevent warping or twisting |

| Cost | Higher, due to quality and visual importance | Lower, focused on support rather than appearance |

Introduction to Face Veneer and Back Veneer in Wood Products

Face veneer refers to the outermost layer of wood applied to furniture or panel surfaces, valued for its aesthetic appeal and grain pattern, enhancing the visual quality of wood products. Back veneer, positioned on the reverse side, provides structural balance and stability, preventing warping or twisting by counteracting the stresses on the face veneer. Both veneers play crucial roles in engineered wood products, optimizing durability while maintaining an attractive finish.

Key Differences Between Face Veneer and Back Veneer

Face veneer exhibits superior grain quality, color consistency, and surface smoothness, making it ideal for visible furniture surfaces. Back veneer typically has lower grade appearance with more knots or imperfections, serving as a structural backing layer rather than for aesthetic purposes. Thickness may also differ, with face veneers generally being thinner and more refined compared to the usually thicker and rougher back veneers.

Material Selection: Choosing Face versus Back Veneer

Face veneer is selected for its aesthetic appeal and superior grain quality, often showcasing unique patterns and colors that enhance furniture or panel surfaces. Back veneer, typically thinner and less visually striking, serves structural purposes and cost efficiency in plywood or laminated wood products. Material selection hinges on balancing visual presentation with durability requirements and budget constraints in woodworking projects.

Manufacturing Processes for Face and Back Veneers

Face veneer undergoes meticulous selection and precise slicing from high-quality logs to ensure exceptional grain patterns and aesthetic appeal, involving processes like rotary cutting or slicing. Back veneer production uses lower-grade wood, emphasizing uniform thickness and stability, typically produced through similar slicing methods but with less stringent quality controls. Both veneers are then dried, graded, and laminated onto substrates, but face veneer requires enhanced finishing techniques to preserve visual excellence.

Aesthetic Considerations: Face Veneer vs Back Veneer

Face veneer features premium wood grains and patterns designed to enhance furniture aesthetics, showcasing rich textures and vibrant colors that elevate the visual appeal. Back veneer often employs lower-grade wood with less attention to grain alignment, serving primarily functional purposes with minimal impact on appearance. Selecting face veneer is crucial for visible surfaces where style and elegance are paramount, while back veneer remains suitable for hidden or structural areas.

Durability and Performance: Comparing Face and Back Veneers

Face veneers are typically crafted from high-quality wood with superior grain patterns, offering enhanced durability and aesthetic appeal, making them ideal for visible surfaces in furniture and cabinetry. Back veneers, often made from lower-grade wood or composite materials, provide structural support but lack the durability and performance characteristics of face veneers. The difference in quality directly impacts the longevity and wear resistance, with face veneers delivering better performance under daily use and environmental exposure.

Cost Implications: Face Veneer versus Back Veneer

Face veneer typically incurs higher costs due to its superior quality and aesthetic appeal, making it ideal for visible surfaces in furniture and cabinetry. Back veneer is generally less expensive as it is applied to concealed areas where appearance is less critical, reducing material and production expenses. Choosing between face veneer and back veneer significantly impacts overall project budget, emphasizing the need for strategic use based on visual requirements and cost efficiency.

Common Applications for Face and Back Veneers

Face veneers are primarily used in high-quality furniture, cabinetry, and decorative paneling where the appearance of the wood grain and finish is critical to the final aesthetic. Back veneers serve functional purposes in furniture construction, providing stability and preventing warping while often being hidden from view. Both veneers complement each other to achieve a balance between visual appeal and structural integrity in wood products.

Sustainability and Sourcing: Face Veneer vs Back Veneer

Face veneer is typically sourced from high-quality, sustainably managed forests to ensure durability and aesthetic appeal, supporting responsible forestry practices and certification standards like FSC. Back veneer often originates from the same log but includes lower-grade wood, promoting full log utilization and reducing waste in the wood supply chain. Prioritizing face veneer for visible surfaces enhances product longevity, while sourcing back veneer aligns with sustainable manufacturing by maximizing resource efficiency.

Tips for Selecting the Right Veneer for Your Project

Face veneer showcases the wood's most attractive grain patterns and is ideal for visible surfaces like furniture and cabinetry, while back veneer serves primarily as a stable backing layer to enhance durability. Selecting the right veneer involves assessing the wood species, grain pattern, and thickness to match the project's aesthetic and structural needs. Prioritize high-quality face veneer with consistent grain for best visual impact and use stable, knot-free back veneer to prevent warping and ensure longevity.

Face veneer vs Back veneer Infographic

materialdif.com

materialdif.com