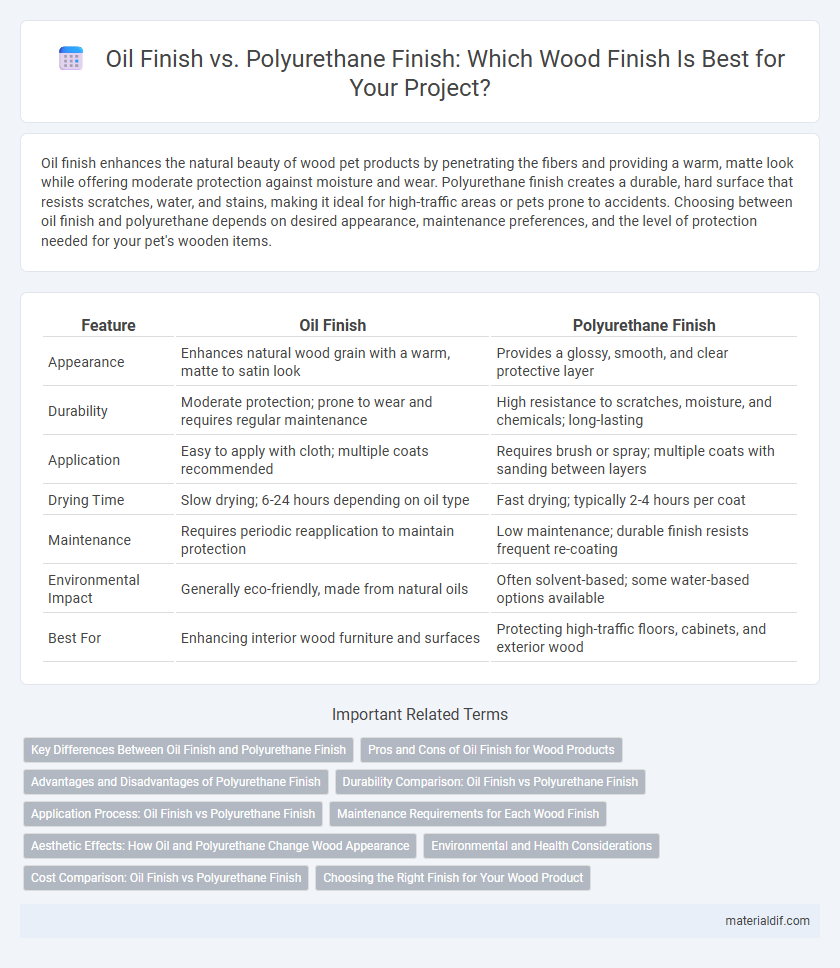

Oil finish enhances the natural beauty of wood pet products by penetrating the fibers and providing a warm, matte look while offering moderate protection against moisture and wear. Polyurethane finish creates a durable, hard surface that resists scratches, water, and stains, making it ideal for high-traffic areas or pets prone to accidents. Choosing between oil finish and polyurethane depends on desired appearance, maintenance preferences, and the level of protection needed for your pet's wooden items.

Table of Comparison

| Feature | Oil Finish | Polyurethane Finish |

|---|---|---|

| Appearance | Enhances natural wood grain with a warm, matte to satin look | Provides a glossy, smooth, and clear protective layer |

| Durability | Moderate protection; prone to wear and requires regular maintenance | High resistance to scratches, moisture, and chemicals; long-lasting |

| Application | Easy to apply with cloth; multiple coats recommended | Requires brush or spray; multiple coats with sanding between layers |

| Drying Time | Slow drying; 6-24 hours depending on oil type | Fast drying; typically 2-4 hours per coat |

| Maintenance | Requires periodic reapplication to maintain protection | Low maintenance; durable finish resists frequent re-coating |

| Environmental Impact | Generally eco-friendly, made from natural oils | Often solvent-based; some water-based options available |

| Best For | Enhancing interior wood furniture and surfaces | Protecting high-traffic floors, cabinets, and exterior wood |

Key Differences Between Oil Finish and Polyurethane Finish

Oil finish penetrates deeply into wood fibers, enhancing natural grain and providing a warm, matte appearance, while polyurethane forms a durable, protective surface layer resistant to scratches and water. Oil finishes require periodic reapplication to maintain their look, whereas polyurethane offers long-lasting protection with minimal maintenance. The choice depends on desired aesthetics and durability, with oil favored for natural beauty and polyurethane for robust protection.

Pros and Cons of Oil Finish for Wood Products

Oil finishes, such as tung or linseed oil, penetrate wood fibers, enhancing natural grain patterns and providing a warm, matte appearance that improves over time with reapplication. They offer easy maintenance and repair but lack the strong protective barrier against scratches, water, and chemicals that polyurethane finishes provide. Oil finishes may darken wood slightly and require more frequent upkeep, making them ideal for indoor furniture where a natural look is preferred over maximum durability.

Advantages and Disadvantages of Polyurethane Finish

Polyurethane finish offers superior durability and resistance to scratches, water, and chemicals, making it ideal for high-traffic wooden surfaces like floors and furniture. Its application provides a clear, hard protective layer that enhances wood's longevity but can sometimes result in a less natural appearance compared to oil finishes. However, polyurethane tends to yellow over time and requires careful sanding between coats for a smooth finish, which may increase labor and maintenance efforts.

Durability Comparison: Oil Finish vs Polyurethane Finish

Oil finish penetrates wood fibers, offering moderate durability and enhancing natural grain, but requires periodic reapplication to maintain protection. Polyurethane finish forms a hard, protective layer on the surface, providing superior resistance to scratches, moisture, and wear, making it more durable for high-traffic or moisture-prone areas. For long-lasting protection and minimal maintenance, polyurethane finish generally outperforms oil finish in durability.

Application Process: Oil Finish vs Polyurethane Finish

Oil finishes penetrate wood fibers, enhancing natural grain while providing moderate protection through multiple thin coats applied with a cloth or brush, requiring periodic reapplication to maintain appearance. Polyurethane finishes form a hard, durable surface film applied with a brush or spray, typically needing fewer coats but longer drying time and sanding between layers for optimal adhesion. The application process of oil finishes is simpler and more forgiving, whereas polyurethane demands careful surface preparation and technique to avoid bubbles or uneven layers.

Maintenance Requirements for Each Wood Finish

Oil finishes penetrate wood fibers, requiring periodic reapplication every 6 to 12 months to maintain water resistance and enhance the natural grain, while polyurethane finishes form a hard, protective surface that lasts 2 to 5 years with minimal maintenance. Cleaning oil-finished wood involves gentle wiping with mild soap and water, avoiding abrasive products to prevent surface damage. Polyurethane surfaces tolerate harsher cleaners and require occasional buffing or polishing to retain sheen and durability.

Aesthetic Effects: How Oil and Polyurethane Change Wood Appearance

Oil finishes penetrate the wood to enhance natural grain patterns, imparting a warm, rich tone with a subtle matte or satin sheen that deepens over time. Polyurethane forms a protective, durable surface layer that can range from glossy to satin, often giving wood a more polished and uniform appearance while slightly raising the grain texture. The choice between oil and polyurethane significantly influences wood aesthetics, with oil providing a natural, organic look and polyurethane delivering a more resilient, high-gloss finish.

Environmental and Health Considerations

Oil finishes, such as linseed and tung oil, offer a natural, low-VOC alternative that allows wood to breathe and age gracefully while minimizing harmful chemical emissions. Polyurethane finishes contain synthetic solvents and plasticizers that release volatile organic compounds (VOCs), contributing to indoor air pollution and posing respiratory risks during application and curing. Choosing oil finishes supports eco-friendliness and reduces toxic exposure, whereas polyurethane provides durability at the cost of greater environmental and health impacts.

Cost Comparison: Oil Finish vs Polyurethane Finish

Oil finish typically costs less initially, with prices around $10 to $20 per quart, making it an economical choice for small projects and touch-ups. Polyurethane finish ranges from $15 to $50 per quart, reflecting its durability and long-lasting protection, which may reduce maintenance expenses over time. Considering total lifecycle costs, polyurethane can offer better value despite a higher upfront investment due to its resistance to wear, chemicals, and moisture.

Choosing the Right Finish for Your Wood Product

Oil finish penetrates deeply into wood fibers, enhancing natural grain patterns and providing a warm, matte appearance, ideal for furniture and wooden utensils requiring frequent handling. Polyurethane finish forms a durable, protective barrier on the surface, offering superior resistance to scratches, water, and heat, making it suitable for flooring and high-traffic wood products. Selecting the right finish depends on the intended use, desired durability, and aesthetic preference, with oil finish favored for natural beauty and polyurethane chosen for robust protection.

Oil Finish vs Polyurethane Finish Infographic

materialdif.com

materialdif.com