Rift sawn wood offers a straighter grain pattern and enhanced stability, making it less prone to warping in pet furniture. Flat sawn wood displays a more varied grain with wider patterns, providing a distinctive aesthetic but reduced resistance to moisture and movement. Choosing rift sawn wood ensures durability and a sleek appearance, ideal for long-lasting pet products.

Table of Comparison

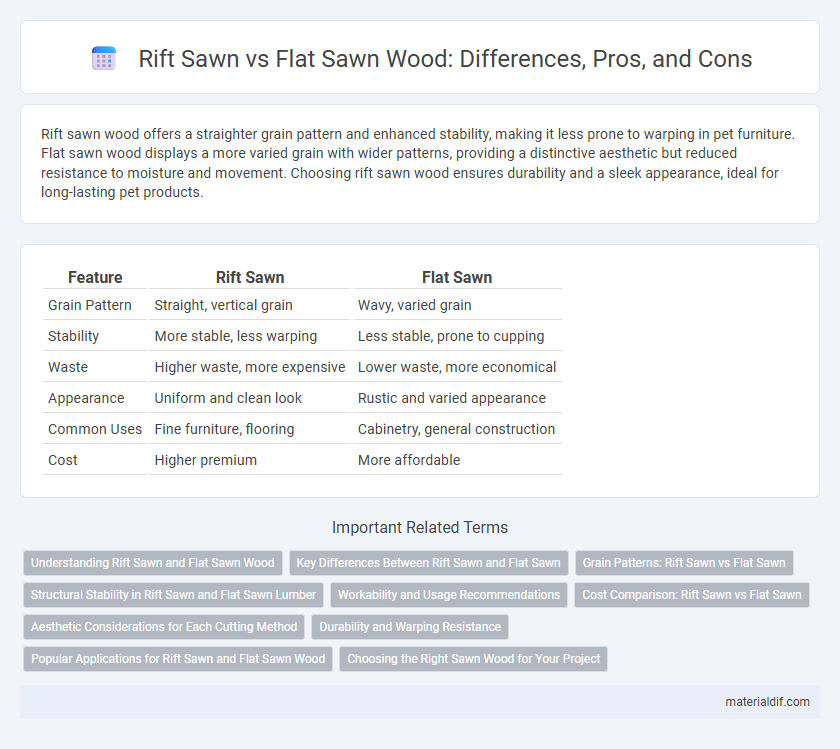

| Feature | Rift Sawn | Flat Sawn |

|---|---|---|

| Grain Pattern | Straight, vertical grain | Wavy, varied grain |

| Stability | More stable, less warping | Less stable, prone to cupping |

| Waste | Higher waste, more expensive | Lower waste, more economical |

| Appearance | Uniform and clean look | Rustic and varied appearance |

| Common Uses | Fine furniture, flooring | Cabinetry, general construction |

| Cost | Higher premium | More affordable |

Understanding Rift Sawn and Flat Sawn Wood

Rift sawn wood is cut at a 30 to 60-degree angle from the growth rings, producing a straight grain pattern that enhances stability and reduces warping. Flat sawn wood, or plain sawn, is cut tangentially to the growth rings, resulting in a distinctive cathedral grain pattern and maximizing yield and cost-efficiency. Understanding these sawing methods helps select the right wood type for applications requiring specific aesthetic appeal, durability, and strength.

Key Differences Between Rift Sawn and Flat Sawn

Rift sawn wood is cut at a 30 to 60-degree angle to the growth rings, producing a straight grain pattern with minimal grain variation, offering superior stability and reduced warping compared to flat sawn wood. Flat sawn lumber is cut tangentially to the growth rings, creating a pronounced cathedral or "flame" grain pattern that is more prone to cupping and shrinking due to uneven grain orientation. Rift sawn wood is often preferred for high-end furniture and flooring where dimensional stability and uniform grain are critical, while flat sawn wood is more commonly used for general construction and decorative purposes because of its cost-efficiency and wider availability.

Grain Patterns: Rift Sawn vs Flat Sawn

Rift sawn wood features straight, uniform grain patterns that enhance strength and create a clean, linear aesthetic ideal for fine woodworking and flooring. Flat sawn wood displays a more varied, cathedral grain pattern that emphasizes natural wood character and offers greater panel stability at a lower cost. These distinct grain orientations impact both the visual appeal and dimensional stability of the wood in construction and furniture applications.

Structural Stability in Rift Sawn and Flat Sawn Lumber

Rift sawn lumber offers superior structural stability due to its vertical grain pattern, which minimizes warping, cup, and twist compared to flat sawn lumber. Flat sawn wood, characterized by its tangential grain, tends to expand and contract more across the width, increasing susceptibility to deformation under variable humidity conditions. This enhanced dimensional stability makes rift sawn lumber ideal for applications requiring consistent strength and reduced movement.

Workability and Usage Recommendations

Rift sawn wood offers superior stability and uniform grain, making it ideal for high-quality furniture and flooring where durability and appearance are critical. Flat sawn wood, with its wider grain patterns, provides easier workability and cost efficiency, suitable for general construction and decorative paneling. Choosing between rift sawn and flat sawn depends on the project's need for structural integrity versus budget and ease of machining.

Cost Comparison: Rift Sawn vs Flat Sawn

Rift sawn wood generally costs more than flat sawn due to higher labor and material waste during milling, as the boards are cut at precise angles to enhance grain stability and aesthetics. Flat sawn wood remains more affordable because it maximizes log yield with faster cutting techniques, resulting in less waste and lower production expenses. Choosing between rift sawn and flat sawn ultimately depends on budget constraints and the desired balance between cost and wood appearance.

Aesthetic Considerations for Each Cutting Method

Rift sawn wood features a straight, tight grain pattern that provides a clean, uniform appearance prized for its refined and elegant look in cabinetry and furniture. Flat sawn wood displays a more varied grain pattern with cathedral or flame shapes, offering a warmer, more rustic aesthetic that highlights the natural character of the wood. Choosing between rift sawn and flat sawn depends on the desired visual effect, with rift sawn appealing to modern, minimalist designs and flat sawn enhancing traditional or casual interiors.

Durability and Warping Resistance

Rift sawn wood exhibits superior durability and warping resistance due to its radial grain pattern, which minimizes wood movement and enhances structural stability. Flat sawn lumber, with its tangential grain alignment, tends to absorb moisture unevenly, making it more prone to warping and less durable under fluctuating environmental conditions. Choosing rift sawn wood is ideal for applications demanding long-term performance and resistance to deformation.

Popular Applications for Rift Sawn and Flat Sawn Wood

Rift sawn wood is commonly used in furniture making, cabinetry, and flooring due to its uniform grain pattern and enhanced stability, which minimizes warping and twisting. Flat sawn wood is popular in construction, paneling, and decorative woodwork because of its affordability and prominent grain patterns that add aesthetic appeal. Both cuts suit different applications based on structural needs and visual preferences, with rift sawn favored for durability and flat sawn for cost-effective material use.

Choosing the Right Sawn Wood for Your Project

Rift sawn wood offers superior dimensional stability and a linear grain pattern, making it ideal for furniture and flooring where durability and aesthetics are crucial. Flat sawn wood provides greater yield and a more varied grain appearance, making it cost-effective and suitable for larger surfaces like paneling and framing. Selecting the right sawn wood depends on balancing budget, visual preference, and the specific performance requirements of your project.

Rift Sawn vs Flat Sawn Infographic

materialdif.com

materialdif.com