Cupping and bowing are common wood deformations caused by moisture imbalance; cupping occurs when the edges of a wood board rise higher than the center, while bowing causes the board to curve along its length. These defects result from uneven drying or exposure to humidity, impacting the wood's stability and usability in construction or furniture making. Proper acclimation and sealing techniques help minimize these distortions, preserving the wood's shape and structural integrity.

Table of Comparison

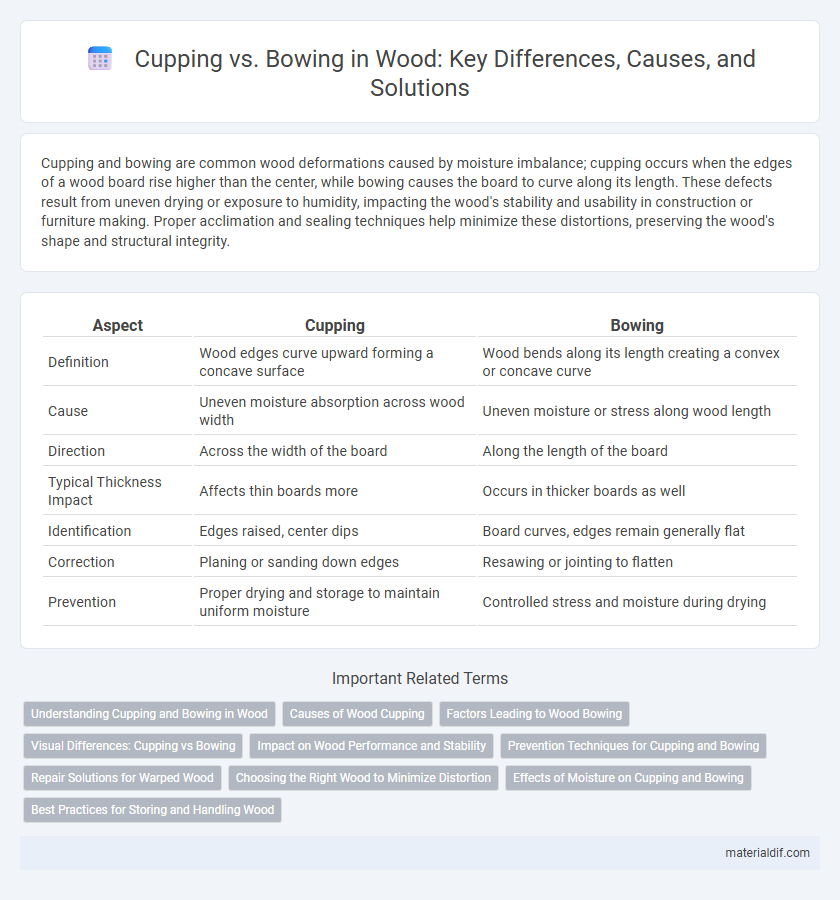

| Aspect | Cupping | Bowing |

|---|---|---|

| Definition | Wood edges curve upward forming a concave surface | Wood bends along its length creating a convex or concave curve |

| Cause | Uneven moisture absorption across wood width | Uneven moisture or stress along wood length |

| Direction | Across the width of the board | Along the length of the board |

| Typical Thickness Impact | Affects thin boards more | Occurs in thicker boards as well |

| Identification | Edges raised, center dips | Board curves, edges remain generally flat |

| Correction | Planing or sanding down edges | Resawing or jointing to flatten |

| Prevention | Proper drying and storage to maintain uniform moisture | Controlled stress and moisture during drying |

Understanding Cupping and Bowing in Wood

Cupping in wood refers to the distortion where the edges of a board curl upward or downward, creating a concave or convex shape across the width, often caused by uneven moisture absorption. Bowing occurs when a board bends along its length, resulting in a curved or arched profile, typically due to internal stresses or improper drying. Understanding these defects is essential for woodworking projects to ensure dimensional stability and structural integrity in furniture, flooring, and cabinetry.

Causes of Wood Cupping

Wood cupping occurs primarily due to uneven moisture absorption and drying, causing the edges of a wood board to expand or contract differently than the center. Variations in grain orientation and environmental humidity fluctuations exacerbate this effect. Improper sealing of wood surfaces and exposure to moisture on one side also contribute significantly to the cupping phenomenon.

Factors Leading to Wood Bowing

Wood bowing occurs primarily due to uneven moisture absorption and drying, causing internal stresses that deform the wood along its length. Factors such as wood grain orientation, environmental humidity fluctuations, and improper storage significantly contribute to bowing. Additionally, the natural shrinkage and swelling properties of wood fibers accentuate the curvature when stress is not evenly distributed.

Visual Differences: Cupping vs Bowing

Cupping causes the edges of a wood board to curve upward, forming a concave shape across the width, which is visible when viewed from above. Bowing results in a lengthwise curvature along the board's surface, creating a convex or concave arc when observed from the side. Visually distinguishing between cupping and bowing is essential for woodworkers to select the appropriate corrective methods for lumber stability.

Impact on Wood Performance and Stability

Cupping causes the wood to bend across its width, creating a concave or convex surface, which can reduce structural stability and affect aesthetic quality in flooring and furniture applications. Bowing results in a lengthwise curvature, compromising dimensional accuracy and making joints and assemblies less secure. Both defects significantly impact wood performance by altering load distribution and increasing susceptibility to moisture-induced deformation and mechanical stress.

Prevention Techniques for Cupping and Bowing

Controlling moisture levels and ensuring proper acclimation of wood before installation significantly reduces the risk of cupping and bowing. Using sealing finishes on all wood surfaces helps prevent uneven moisture absorption, which is a primary cause of these deformations. Adequate subfloor ventilation and installing wood with the grain perpendicular to moisture sources further enhance stability and minimize warping.

Repair Solutions for Warped Wood

Cupping and bowing are common forms of warped wood that require distinct repair solutions to restore structural integrity. Cupped wood, characterized by edges higher than the center, can be remedied by acclimating the wood to a balanced humidity environment and using moisture control methods such as sealing and controlled drying. Bowed wood, which forms a gentle curve along the length, often demands mechanical correction techniques including clamping, applying weights, or employing steam bending to gradually restore the wood's flatness.

Choosing the Right Wood to Minimize Distortion

Selecting wood with stable grain orientation and low moisture content helps minimize cupping and bowing distortions in woodworking projects. Quarter-sawn lumber offers higher dimensional stability compared to plain-sawn wood, reducing the likelihood of warping. Proper drying and acclimatization of hardwoods like oak or maple further ensure minimal surface deformation and structural integrity.

Effects of Moisture on Cupping and Bowing

Moisture absorption causes wood fibers to swell unevenly, leading to cupping where the board edges rise higher than the center. Bowing occurs when moisture causes differential expansion along the board's length, bending it into a concave or convex curve. Both defects compromise wood stability and structural integrity in construction and woodworking projects.

Best Practices for Storing and Handling Wood

Proper storage of wood to prevent cupping involves maintaining consistent humidity levels around 6-8% and stacking boards flat with spacers to ensure even air circulation. Bowing can be minimized by storing wood in a dry, temperature-controlled environment and avoiding exposure to direct sunlight or uneven weight distribution. Using kiln-dried lumber and acclimating wood to its environment before use also supports dimensional stability and reduces the risk of warping defects.

Cupping vs Bowing Infographic

materialdif.com

materialdif.com