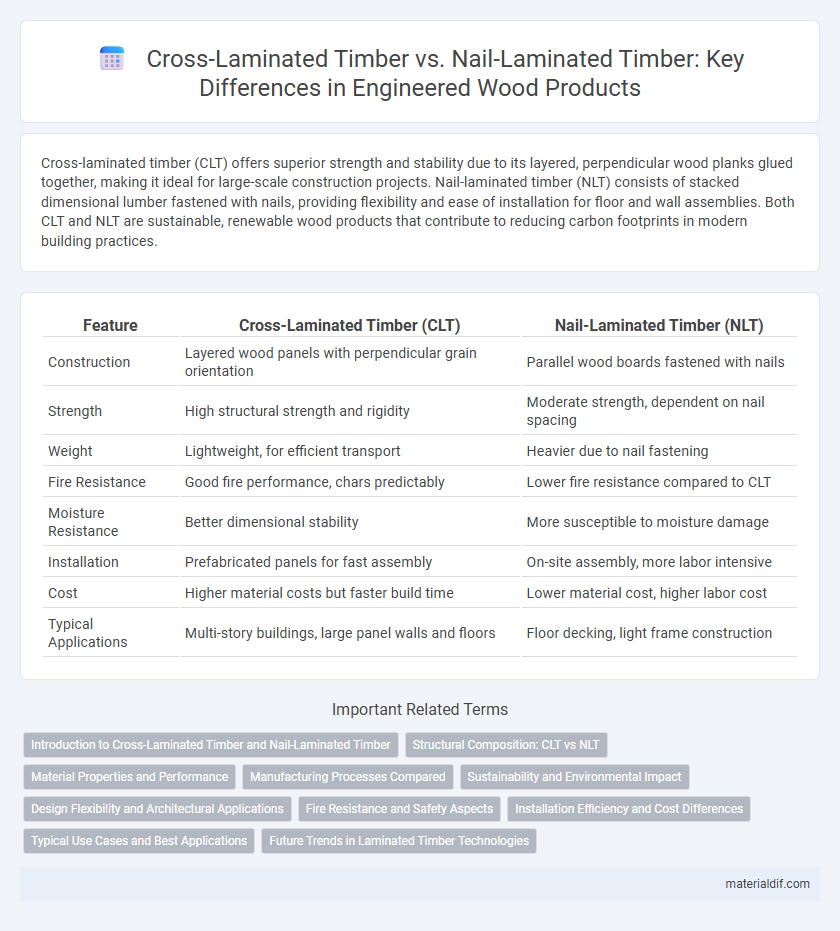

Cross-laminated timber (CLT) offers superior strength and stability due to its layered, perpendicular wood planks glued together, making it ideal for large-scale construction projects. Nail-laminated timber (NLT) consists of stacked dimensional lumber fastened with nails, providing flexibility and ease of installation for floor and wall assemblies. Both CLT and NLT are sustainable, renewable wood products that contribute to reducing carbon footprints in modern building practices.

Table of Comparison

| Feature | Cross-Laminated Timber (CLT) | Nail-Laminated Timber (NLT) |

|---|---|---|

| Construction | Layered wood panels with perpendicular grain orientation | Parallel wood boards fastened with nails |

| Strength | High structural strength and rigidity | Moderate strength, dependent on nail spacing |

| Weight | Lightweight, for efficient transport | Heavier due to nail fastening |

| Fire Resistance | Good fire performance, chars predictably | Lower fire resistance compared to CLT |

| Moisture Resistance | Better dimensional stability | More susceptible to moisture damage |

| Installation | Prefabricated panels for fast assembly | On-site assembly, more labor intensive |

| Cost | Higher material costs but faster build time | Lower material cost, higher labor cost |

| Typical Applications | Multi-story buildings, large panel walls and floors | Floor decking, light frame construction |

Introduction to Cross-Laminated Timber and Nail-Laminated Timber

Cross-Laminated Timber (CLT) consists of layers of lumber boards stacked crosswise and glued together, providing exceptional strength, stability, and dimensional accuracy. Nail-Laminated Timber (NLT) is constructed by stacking dimensional lumber boards side-by-side and fastening them with nails or screws, offering flexibility and ease of on-site assembly. Both engineered wood products enhance structural performance and sustainability in modern construction but differ in manufacturing methods and typical applications.

Structural Composition: CLT vs NLT

Cross-Laminated Timber (CLT) features multiple layers of lumber boards stacked crosswise at 90-degree angles, creating a panel with enhanced rigidity and multidirectional strength. Nail-Laminated Timber (NLT) consists of dimension lumber boards stacked edgewise and fastened with nails or screws, providing a strong, unidirectional load-bearing capacity. The cross-lamination in CLT offers superior dimensional stability and resistance to warping compared to the simpler layered assembly of NLT.

Material Properties and Performance

Cross-laminated timber (CLT) offers superior strength and dimensional stability due to its cross-grain layering, enhancing load-bearing capacity and resistance to warping compared to nail-laminated timber (NLT), which relies on mechanically fastened lumber layers. CLT's engineered fabrication results in greater fire resistance and consistent mechanical properties, while NLT is valued for ease of onsite construction and flexibility in design modifications. Both materials perform well structurally, but CLT's enhanced stiffness and moisture resistance make it preferable for large-scale, high-performance applications.

Manufacturing Processes Compared

Cross-Laminated Timber (CLT) is manufactured by stacking layers of kiln-dried lumber perpendicular to each other, bonded with structural adhesives under pressure, resulting in high strength and dimensional stability. Nail-Laminated Timber (NLT) is produced by fastening dimensional lumber layers together with nails or screws without adhesives, allowing for faster, less complex assembly but with reduced rigidity compared to CLT. The manufacturing process of CLT requires precise fabrication in controlled environments, while NLT can be assembled on-site or in less specialized facilities, impacting cost and installation time.

Sustainability and Environmental Impact

Cross-laminated timber (CLT) offers superior sustainability due to its layered structure, which maximizes strength while using less wood compared to nail-laminated timber (NLT). CLT's production involves fewer chemical adhesives, reducing harmful emissions and enhancing recyclability, whereas NLT often requires more metal fasteners that complicate recycling. Both materials sequester carbon efficiently, but CLT's prefab nature and optimized dimensions generally result in lower waste and a smaller environmental footprint.

Design Flexibility and Architectural Applications

Cross-Laminated Timber (CLT) offers superior design flexibility due to its prefabricated panels with alternating wood layers, enabling complex shapes and large spans ideal for modern architectural applications like multi-story buildings. Nail-Laminated Timber (NLT), constructed by nailing dimensional lumber perpendicular to each other, suits simpler designs with greater adaptability for on-site modifications and renovation projects. Both materials support sustainable construction but CLT's engineered precision often results in higher structural performance and aesthetic versatility in contemporary architectural design.

Fire Resistance and Safety Aspects

Cross-Laminated Timber (CLT) offers superior fire resistance compared to Nail-Laminated Timber (NLT) due to its thicker, compact layers that char slowly and retain structural integrity longer under fire exposure. CLT's manufacturing process ensures consistent quality and density, enhancing its performance in fire safety tests and compliance with stringent building codes. NLT, while structurally sound, has more exposed fasteners and gaps, increasing vulnerability to fire penetration and reducing overall fire resistance.

Installation Efficiency and Cost Differences

Cross-Laminated Timber (CLT) offers faster installation due to its prefabricated, solid panels that require fewer on-site adjustments compared to Nail-Laminated Timber (NLT), which involves assembling multiple dimensional lumber layers with nails. CLT panels deliver higher structural stability, reducing labor costs and minimizing construction time, whereas NLT's traditional nailing process increases labor intensity and duration. Cost differences highlight CLT's higher upfront material price balanced by savings in installation labor and project schedule, while NLT remains less expensive initially but may result in higher overall labor expenses and longer construction timelines.

Typical Use Cases and Best Applications

Cross-Laminated Timber (CLT) is ideal for large-scale commercial and residential buildings due to its high strength, dimensional stability, and excellent fire resistance, making it suitable for multi-story structures and complex architectural designs. Nail-Laminated Timber (NLT) is commonly used in floor and roof decking where speed of installation and cost-effectiveness are priorities, often favored in renovation projects and smaller-scale buildings. CLT offers superior performance in modular construction and prefabrication, while NLT excels in straightforward wood frame applications requiring quick assembly.

Future Trends in Laminated Timber Technologies

Cross-laminated timber (CLT) and nail-laminated timber (NLT) are evolving with innovations in digital fabrication and engineered wood composites, enhancing structural performance and sustainability. Advanced adhesives and smart sensors integrated into CLT and NLT panels enable real-time monitoring of building health, promoting adaptive maintenance and longer lifespans. Future trends prioritize carbon-neutral materials and modular construction, positioning laminated timber as a key driver in green urban development.

Cross-Laminated Timber vs Nail-Laminated Timber Infographic

materialdif.com

materialdif.com