Edge glued panels are created by joining narrow wood strips along their edges to form a wider board, offering a smooth, continuous surface with minimal visible seams, ideal for furniture and cabinetry. Finger jointed panels consist of interlocking finger-like projections that provide strong mechanical bonds, enhancing structural stability and reducing material waste, commonly used in construction and moldings. Both techniques improve wood utilization and strength, but edge glued panels emphasize surface appearance while finger joints prioritize joint integrity.

Table of Comparison

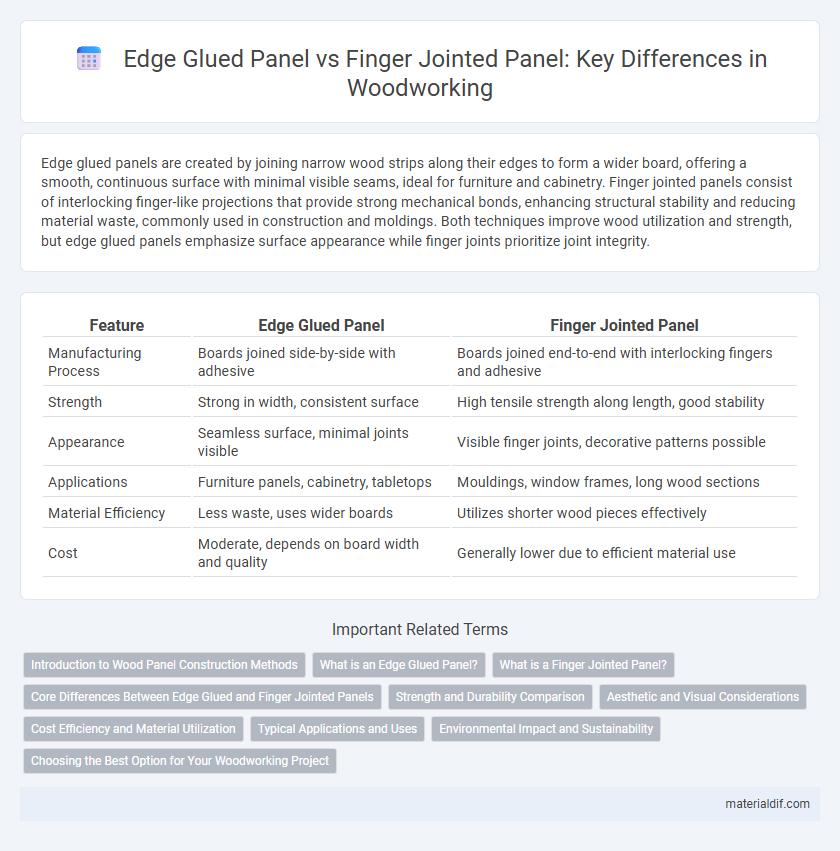

| Feature | Edge Glued Panel | Finger Jointed Panel |

|---|---|---|

| Manufacturing Process | Boards joined side-by-side with adhesive | Boards joined end-to-end with interlocking fingers and adhesive |

| Strength | Strong in width, consistent surface | High tensile strength along length, good stability |

| Appearance | Seamless surface, minimal joints visible | Visible finger joints, decorative patterns possible |

| Applications | Furniture panels, cabinetry, tabletops | Mouldings, window frames, long wood sections |

| Material Efficiency | Less waste, uses wider boards | Utilizes shorter wood pieces effectively |

| Cost | Moderate, depends on board width and quality | Generally lower due to efficient material use |

Introduction to Wood Panel Construction Methods

Edge glued panels consist of wooden boards joined along their edges using strong adhesives to create wide, stable surfaces ideal for furniture and cabinetry. Finger jointed panels utilize interlocking "fingers" cut into the ends of shorter wood pieces, which are glued together to form longer, dimensionally stable boards. Both methods enhance wood panel stability and usability, but edge glued panels offer smoother, more seamless surfaces, while finger jointed panels are valued for maximizing wood yield and reducing waste.

What is an Edge Glued Panel?

An edge glued panel consists of multiple narrow wood boards joined side by side along their edges using strong adhesives, creating a larger, stable panel suitable for furniture and cabinetry. This technique enhances dimensional stability by reducing the risk of warping compared to solid wood planks. Edge glued panels provide a seamless appearance with consistent grain patterns, making them ideal for high-quality woodworking projects.

What is a Finger Jointed Panel?

A finger jointed panel is a type of wood product created by joining shorter pieces of wood using interlocking finger-like projections and adhesive, resulting in long, stable boards. This technique enhances the material's strength and reduces waste by utilizing smaller wood sections that might otherwise be discarded. Finger jointed panels are commonly used in furniture, cabinetry, and construction due to their durability and cost-effectiveness compared to solid wood or edge glued panels.

Core Differences Between Edge Glued and Finger Jointed Panels

Edge glued panels consist of solid wood strips joined along their edges to form wider boards, providing a uniform appearance and strong structural integrity. Finger jointed panels are made by interlocking multiple short wood pieces with finger-like cuts, enhancing stability and minimizing waste while allowing for longer panel lengths. The core difference lies in edge glued panels offering consistent grain patterns and strength, whereas finger jointed panels prioritize material efficiency and dimensional stability through engineered joints.

Strength and Durability Comparison

Edge glued panels typically offer superior strength and stability due to continuous grain alignment, allowing them to withstand heavy loads and resist warping effectively. Finger jointed panels rely on interlocking finger joints that provide good dimensional stability but may exhibit lower overall strength under stress compared to edge glued boards. Durability varies as edge glued panels resist moisture penetration better, while finger jointed panels can be more prone to joint failure if exposed to fluctuating humidity conditions.

Aesthetic and Visual Considerations

Edge glued panels provide a seamless, continuous wood surface with fewer visible joints, enhancing the natural appearance and ideal for high-end furniture and cabinetry where aesthetics matter. Finger jointed panels display a distinct, patterned joint line that can add a decorative, geometric element but may not suit all design styles, especially those seeking a smooth, uninterrupted grain. Selecting between these panels depends on the desired visual appeal and whether a flawless or textured finish aligns better with the project's aesthetic goals.

Cost Efficiency and Material Utilization

Edge glued panels offer superior material utilization by joining smaller wood pieces side-by-side, minimizing waste and allowing for wider boards ideal for furniture making, often resulting in higher upfront costs due to precise manufacturing. Finger jointed panels, created by interlocking smaller wood segments end-to-end, enhance cost efficiency by utilizing shorter or lower-grade wood pieces with less waste, making them a budget-friendly choice for structural applications. The optimal choice depends on balancing cost constraints with desired material performance, where edge glued panels provide premium aesthetics and strength, while finger jointed panels maximize economic use of raw resources.

Typical Applications and Uses

Edge glued panels are commonly used for furniture, cabinetry, and tabletops due to their ability to create wide, solid surfaces with a smooth appearance, making them ideal for visible applications requiring strength and aesthetics. Finger jointed panels are frequently employed in construction, moldings, and interior trim where dimensional stability and efficient use of smaller wood pieces are prioritized. Both panels optimize wood resources, but edge glued panels excel in load-bearing and decorative uses while finger jointed panels are suited for structural and functional elements.

Environmental Impact and Sustainability

Edge glued panels typically use solid wood strips bonded with strong adhesives, resulting in high material efficiency and reduced wood waste compared to traditional boards. Finger jointed panels utilize shorter wood pieces joined with interlocking fingers and adhesive, enabling the use of smaller, often reclaimed timber, which enhances resource sustainability by maximizing lumber yield. Both methods contribute to environmentally friendly wood product solutions, but finger jointing often promotes higher sustainability through better utilization of scrap wood and reduced virgin timber consumption.

Choosing the Best Option for Your Woodworking Project

Edge glued panels provide superior strength and a seamless appearance by joining wood boards along their edges, making them ideal for wide, flat surfaces such as tabletops and cabinetry. Finger jointed panels offer enhanced stability and efficient use of shorter wood pieces by interlocking fingers that create a durable and visually distinct joint, suitable for structural components and decorative elements. Selecting the best option depends on project requirements for strength, aesthetics, and material availability, with edge glued panels preferred for smooth, continuous surfaces and finger jointed panels favored for maximizing wood usage and joint strength.

Edge glued panel vs Finger jointed panel Infographic

materialdif.com

materialdif.com