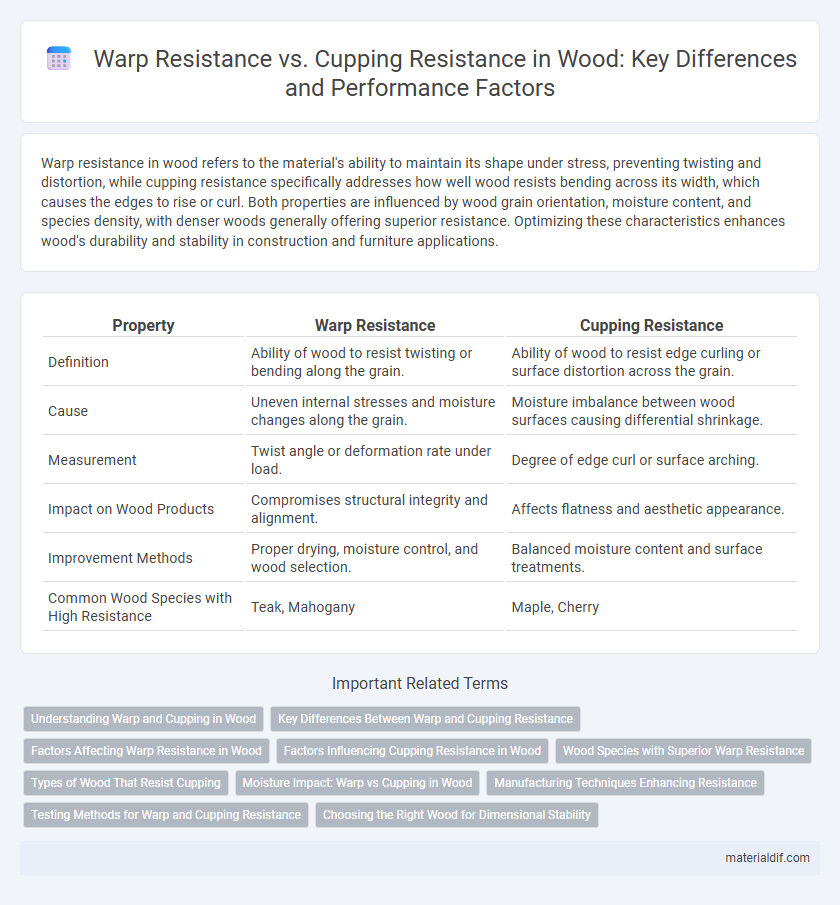

Warp resistance in wood refers to the material's ability to maintain its shape under stress, preventing twisting and distortion, while cupping resistance specifically addresses how well wood resists bending across its width, which causes the edges to rise or curl. Both properties are influenced by wood grain orientation, moisture content, and species density, with denser woods generally offering superior resistance. Optimizing these characteristics enhances wood's durability and stability in construction and furniture applications.

Table of Comparison

| Property | Warp Resistance | Cupping Resistance |

|---|---|---|

| Definition | Ability of wood to resist twisting or bending along the grain. | Ability of wood to resist edge curling or surface distortion across the grain. |

| Cause | Uneven internal stresses and moisture changes along the grain. | Moisture imbalance between wood surfaces causing differential shrinkage. |

| Measurement | Twist angle or deformation rate under load. | Degree of edge curl or surface arching. |

| Impact on Wood Products | Compromises structural integrity and alignment. | Affects flatness and aesthetic appearance. |

| Improvement Methods | Proper drying, moisture control, and wood selection. | Balanced moisture content and surface treatments. |

| Common Wood Species with High Resistance | Teak, Mahogany | Maple, Cherry |

Understanding Warp and Cupping in Wood

Warp resistance in wood refers to the material's ability to resist distortion along its length, preventing bending or twisting under stress, while cupping resistance specifically addresses the wood's tendency to curve across its width, leading to a concave or convex surface. Understanding the cellular structure and moisture content of wood is essential, as uneven moisture absorption causes differential shrinkage, which triggers warping or cupping. High-density hardwoods with tighter grain patterns generally exhibit superior warp and cupping resistance due to their enhanced structural stability and reduced susceptibility to moisture-induced deformation.

Key Differences Between Warp and Cupping Resistance

Warp resistance refers to a wood's ability to maintain its original flat shape without bending or twisting along its grain, while cupping resistance is the wood's capacity to resist bending across its width, causing the edges to curl up or down. The key difference lies in the direction of deformation: warp affects longitudinal straightness, whereas cupping affects crosswise flatness. Both resistances depend heavily on wood species, moisture content, and grain orientation.

Factors Affecting Warp Resistance in Wood

Factors affecting warp resistance in wood include moisture content variation, grain orientation, and wood species density. High moisture gradients cause uneven swelling or shrinking, leading to warping, while straight grain patterns enhance dimensional stability. Wood species with denser cell structures generally exhibit stronger resistance to warping compared to lighter, porous species.

Factors Influencing Cupping Resistance in Wood

Cupping resistance in wood primarily depends on moisture content, wood species, and grain orientation, which affect how the wood expands and contracts unevenly. High-density hardwoods generally display better cupping resistance due to their tighter cell structure and lower moisture absorption rates. Proper drying and sealing treatments further enhance cupping resistance by stabilizing the wood's moisture exchange with the environment.

Wood Species with Superior Warp Resistance

Wood species with superior warp resistance, such as White Oak and Teak, demonstrate excellent stability under varying moisture conditions, reducing the risk of dimensional changes. These hardwoods possess dense cellular structures that effectively minimize internal stresses, leading to less deformation compared to softer woods. Superior warp resistance enhances the durability and lifespan of wooden products, especially in environments prone to humidity fluctuations.

Types of Wood That Resist Cupping

Hardwoods like teak, mahogany, and white oak exhibit superior resistance to cupping due to their dense grain structure and natural oils that repel moisture. Engineered woods with multi-layered construction also minimize cupping by balancing internal stresses. Choosing stable woods with low moisture absorption significantly reduces the risk of surface deformation and maintains dimensional stability in humid environments.

Moisture Impact: Warp vs Cupping in Wood

Warp resistance in wood primarily addresses the material's ability to maintain dimensional stability along its length when exposed to moisture variations, while cupping resistance focuses on the wood's capacity to resist edge-to-edge distortion caused by differential moisture absorption across the grain. Moisture impact on warp often results from uneven drying or humidity changes that cause longitudinal shrinkage or expansion, whereas cupping occurs due to moisture gradients across the wood's thickness, leading to curvature. Effective moisture management and selecting wood species with low shrinkage coefficients are crucial for minimizing both warp and cupping in woodworking applications.

Manufacturing Techniques Enhancing Resistance

Advanced manufacturing techniques such as kiln drying and controlled moisture conditioning significantly enhance wood's warp resistance by stabilizing internal stresses and reducing moisture content variability. Precision machining and the application of resin treatments improve cupping resistance by reinforcing wood fibers and creating a more uniform surface tension. These combined processes optimize dimensional stability, crucial for high-performance wood products in construction and furniture-making.

Testing Methods for Warp and Cupping Resistance

Warp resistance and cupping resistance in wood are assessed through standardized testing methods such as ASTM D1037 and ISO 16983, which evaluate dimensional changes under controlled moisture and temperature conditions. Warp resistance tests measure the wood's ability to maintain flatness by recording deformation over time, while cupping resistance tests assess the degree of edge curling by measuring the curvature across the board's width. Precise measurement tools like digital calipers and laser scanners ensure accurate quantification of warping and cupping, critical for predicting wood performance in varying environmental settings.

Choosing the Right Wood for Dimensional Stability

Warp resistance measures wood's ability to maintain shape under stress, while cupping resistance indicates how well the wood prevents edges from bending or curling. Woods with high density and tight grain structures, such as white oak and hard maple, offer superior dimensional stability by minimizing both warp and cup tendencies. Selecting wood species with balanced warp and cupping resistance ensures durability and maintains the integrity of furniture, flooring, and cabinetry in varying environmental conditions.

Warp Resistance vs Cupping Resistance Infographic

materialdif.com

materialdif.com