Particle board consists of wood chips and sawdust bonded with resin, offering a cost-effective and smooth surface ideal for furniture and cabinetry, but it is less moisture-resistant and prone to swelling. Oriented Strand Board (OSB) is made from layers of wood strands arranged in specific orientations and compressed with adhesives, providing greater strength and durability, making it suitable for structural applications like flooring and wall sheathing. While particle board excels in affordability and finish quality, OSB delivers superior load-bearing capacity and moisture tolerance in construction projects.

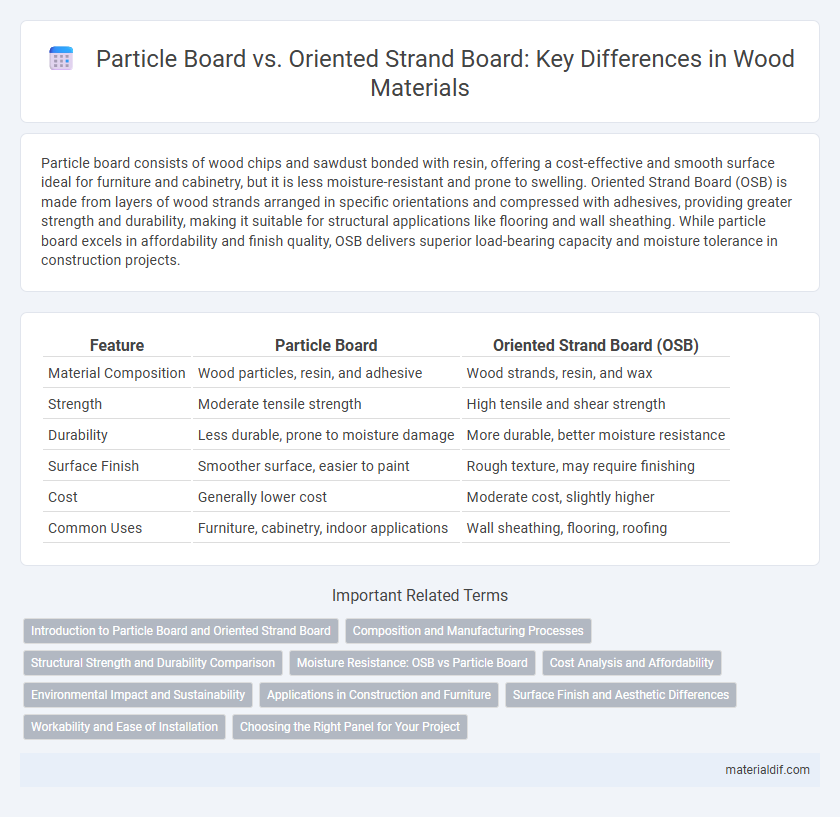

Table of Comparison

| Feature | Particle Board | Oriented Strand Board (OSB) |

|---|---|---|

| Material Composition | Wood particles, resin, and adhesive | Wood strands, resin, and wax |

| Strength | Moderate tensile strength | High tensile and shear strength |

| Durability | Less durable, prone to moisture damage | More durable, better moisture resistance |

| Surface Finish | Smoother surface, easier to paint | Rough texture, may require finishing |

| Cost | Generally lower cost | Moderate cost, slightly higher |

| Common Uses | Furniture, cabinetry, indoor applications | Wall sheathing, flooring, roofing |

Introduction to Particle Board and Oriented Strand Board

Particle board is an engineered wood product made by compressing wood chips, sawmill shavings, and resin under high pressure and heat, resulting in a dense, smooth surface ideal for furniture and cabinetry. Oriented strand board (OSB) consists of large wood strands arranged in specific orientations and bonded with adhesives, providing superior strength and moisture resistance compared to particle board. Both materials serve as cost-effective alternatives to solid wood in construction and cabinetry, with OSB often preferred for structural applications due to its durability.

Composition and Manufacturing Processes

Particle board consists of wood chips, sawdust, and resin compressed under heat and pressure, creating a dense, uniform panel ideal for furniture and cabinetry. Oriented Strand Board (OSB) is composed of long, thin wood strands aligned in specific directions and bonded with adhesives, resulting in a sturdy panel with superior strength and moisture resistance compared to particle board. The manufacturing process of particle board involves random distribution of wood particles, while OSB manufacturing uses directional layering that enhances structural performance in construction applications.

Structural Strength and Durability Comparison

Particle board, composed of compressed wood chips and adhesive, offers moderate structural strength suitable for interior applications but lacks high durability under moisture exposure. Oriented Strand Board (OSB), made from layered strands of wood arranged in specific orientations, provides superior strength and rigidity, making it ideal for load-bearing walls and subflooring. OSB exhibits enhanced durability and resistance to warping and impact compared to particle board, especially in environments with fluctuating humidity and temperature.

Moisture Resistance: OSB vs Particle Board

Oriented Strand Board (OSB) demonstrates superior moisture resistance compared to particle board due to its layered, cross-oriented wood strands that enhance water repellency and structural integrity. Particle board, composed of wood particles bonded with resin, tends to absorb moisture more readily, leading to swelling, warping, and reduced durability in damp environments. As a result, OSB is often preferred for subflooring and exterior sheathing where exposure to moisture is a concern.

Cost Analysis and Affordability

Particle board generally offers a lower upfront cost compared to oriented strand board (OSB), making it a budget-friendly option for interior projects with minimal structural demands. OSB provides greater strength and durability, which can translate to long-term savings in applications requiring load-bearing capacity despite its higher initial price. Evaluating project-specific requirements and lifespan expectations is crucial to determine the most cost-effective material choice between particle board and OSB.

Environmental Impact and Sustainability

Particle board and oriented strand board (OSB) differ significantly in environmental impact and sustainability, with OSB generally considered more eco-friendly due to its use of fast-growing, small-diameter trees and efficient manufacturing processes that utilize almost entire logs. Particle board often incorporates recycled wood fibers and adhesives that may emit formaldehyde, raising concerns about indoor air quality and long-term environmental effects. OSB's durability and recyclability contribute to reduced waste and a lower carbon footprint, making it a preferred sustainable choice in construction and furniture production.

Applications in Construction and Furniture

Particle board offers excellent affordability and smooth surface finish, making it ideal for indoor furniture like cabinets, shelving, and countertops. Oriented Strand Board (OSB) provides superior strength and moisture resistance, commonly used for subflooring, wall sheathing, and roof decking in residential and commercial construction. The choice between particle board and OSB depends on load-bearing requirements and exposure to environmental conditions in building and furniture projects.

Surface Finish and Aesthetic Differences

Particle board features a smooth surface finish that is ideal for laminates and veneers, offering a uniform appearance suitable for indoor furniture. Oriented Strand Board (OSB) displays a distinctive, textured surface made of large wood strands, providing a rustic and industrial aesthetic often used in exposed structural applications. The visual contrast between particle board's clean finish and OSB's rugged texture significantly influences their selection based on design preferences and functional requirements.

Workability and Ease of Installation

Particle board offers superior workability due to its smooth surface and uniform texture, making it easier to cut, drill, and shape with standard woodworking tools. Oriented strand board (OSB), while structurally robust, is denser and more prone to splintering, which can complicate cutting and fastening processes during installation. Both materials require pre-drilling for screws to avoid splitting, but particle board's lighter weight generally facilitates easier handling and quicker installation on site.

Choosing the Right Panel for Your Project

Particle board offers a smooth surface ideal for laminates and interior applications, making it cost-effective for furniture and cabinetry. Oriented Strand Board (OSB) provides superior structural strength and moisture resistance, suitable for subflooring, roofing, and exterior walls. Selecting the right panel depends on project requirements like load-bearing capacity, exposure to moisture, and finished appearance.

Particle Board vs Oriented Strand Board Infographic

materialdif.com

materialdif.com