Kiln-dried wood undergoes a controlled heating process that rapidly removes moisture, resulting in enhanced stability and reduced susceptibility to warping or insect damage compared to air-dried wood. Air-dried wood is naturally dried outdoors, allowing for slower moisture evaporation that preserves the wood's natural oils but may retain higher moisture content. Choosing between kiln-dried and air-dried wood depends on the specific needs of a project, with kiln drying ideal for precision and durability, while air drying suits traditional woodworking and environmentally conscious applications.

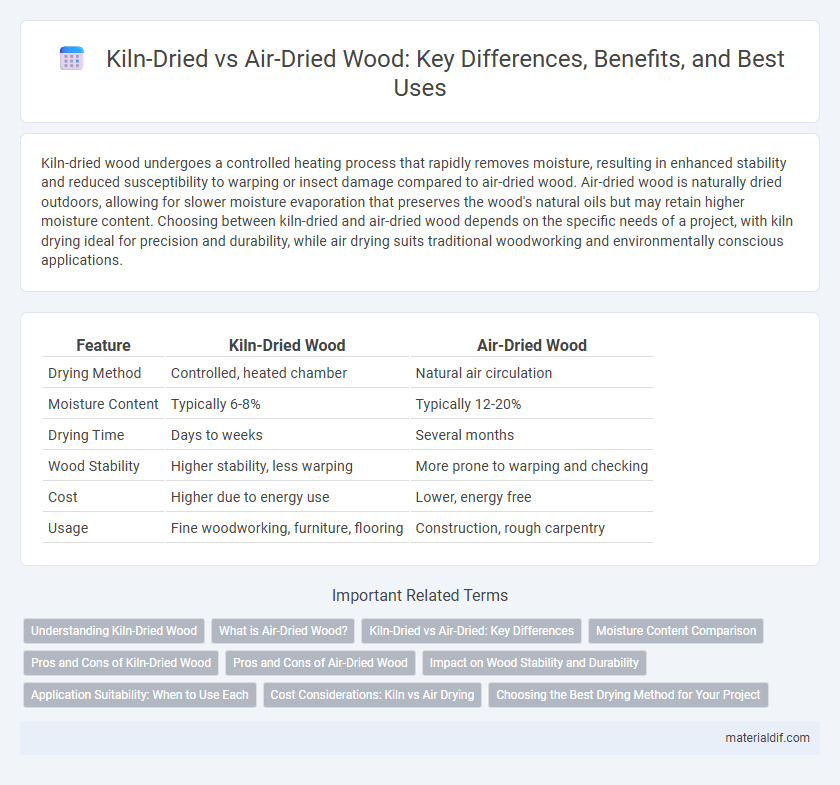

Table of Comparison

| Feature | Kiln-Dried Wood | Air-Dried Wood |

|---|---|---|

| Drying Method | Controlled, heated chamber | Natural air circulation |

| Moisture Content | Typically 6-8% | Typically 12-20% |

| Drying Time | Days to weeks | Several months |

| Wood Stability | Higher stability, less warping | More prone to warping and checking |

| Cost | Higher due to energy use | Lower, energy free |

| Usage | Fine woodworking, furniture, flooring | Construction, rough carpentry |

Understanding Kiln-Dried Wood

Kiln-dried wood undergoes a controlled heating process in a specialized oven, reducing moisture content to 6-8%, which enhances dimensional stability and resistance to warping. This precise drying method minimizes fungal growth and insect infestation compared to air-dried wood, making it ideal for indoor furniture and construction. Understanding kiln-dried wood is critical for selecting materials with superior strength, consistent quality, and improved longevity.

What is Air-Dried Wood?

Air-dried wood is timber that has been dried naturally by stacking it in well-ventilated areas, allowing moisture to evaporate over time without artificial heat. This process typically reduces the wood's moisture content to about 12-15%, making it more stable and less prone to warping compared to green wood. Commonly used in woodworking and construction, air-dried wood retains some natural oils and characteristics, often preferred for its cost-effectiveness and slower drying benefits.

Kiln-Dried vs Air-Dried: Key Differences

Kiln-dried wood is subjected to controlled heat and humidity in a kiln, reducing moisture content faster and resulting in more stable and less warp-prone lumber compared to air-dried wood, which dries naturally over months to years with exposure to atmospheric conditions. Kiln drying typically achieves moisture levels of 6-8%, making the wood ideal for indoor use, while air-dried wood retains higher moisture content, often around 12-15%, suitable for outdoor applications where some moisture is acceptable. The accelerated drying process in kilns also eliminates fungi and insects, increasing wood durability and structural integrity compared to the slower air-drying method.

Moisture Content Comparison

Kiln-dried wood typically contains a moisture content between 6% and 8%, achieved through controlled heat and humidity processes that ensure faster and more uniform drying. Air-dried wood moisture content varies widely, often ranging from 12% to 20%, depending on environmental conditions and drying duration. Lower moisture content in kiln-dried wood reduces the risk of warping, splitting, and fungal decay compared to air-dried wood.

Pros and Cons of Kiln-Dried Wood

Kiln-dried wood offers superior moisture control, reducing the risk of warping, splitting, and insect infestation compared to air-dried wood. The accelerated drying process in a kiln also ensures consistent quality and strength, making it ideal for precise woodworking projects and furniture manufacturing. However, kiln drying is energy-intensive and costly, potentially causing the wood to become brittle or lose some natural characteristics if not carefully managed.

Pros and Cons of Air-Dried Wood

Air-dried wood offers superior moisture retention, reducing the risk of cracking and warping compared to kiln-dried lumber. This method is more energy-efficient and environmentally friendly, as it relies on natural air circulation rather than intensive heat processing. However, air-dried wood has a longer drying time, which may delay construction projects and increase exposure to potential contamination or fungal growth.

Impact on Wood Stability and Durability

Kiln-dried wood offers enhanced stability and durability due to its controlled drying process, which reduces moisture content uniformly and minimizes the risk of warping and cracking. Air-dried wood retains higher moisture levels, making it more susceptible to dimensional changes and fungal decay over time. Properly kiln-dried lumber is preferred in construction and cabinetry for its consistent strength and long-term performance.

Application Suitability: When to Use Each

Kiln-dried wood is ideal for indoor furniture, cabinetry, and flooring where precise moisture content and stability are crucial to prevent warping and shrinkage. Air-dried wood suits outdoor applications, rustic furniture, and construction projects where slight moisture variations are less critical, and natural drying enhances durability. Choosing between kiln-dried and air-dried wood depends on the specific moisture requirements and environmental exposure of the intended project.

Cost Considerations: Kiln vs Air Drying

Kiln-dried wood generally incurs higher upfront costs due to specialized equipment and energy consumption, while air-dried wood offers a more economical option by utilizing natural drying processes with minimal expenses. Despite the initial expense, kiln drying reduces drying time significantly, potentially lowering inventory holding costs and minimizing defects from uneven drying. Choosing between kiln and air drying depends on balancing immediate budget constraints against long-term production efficiency and wood quality requirements.

Choosing the Best Drying Method for Your Project

Kiln-dried wood offers consistent moisture levels around 6-8%, reducing the risk of warping and making it ideal for precision woodworking and indoor projects. Air-dried wood requires several months to years depending on climate, maintaining a natural drying process that preserves wood strength and is cost-effective for large volumes or outdoor use. Selecting the best drying method depends on project requirements for stability, timeline, and budget, with kiln-drying preferred for fast, uniform results and air-drying favored for traditional, eco-friendly approaches.

Kiln-Dried vs Air-Dried Infographic

materialdif.com

materialdif.com