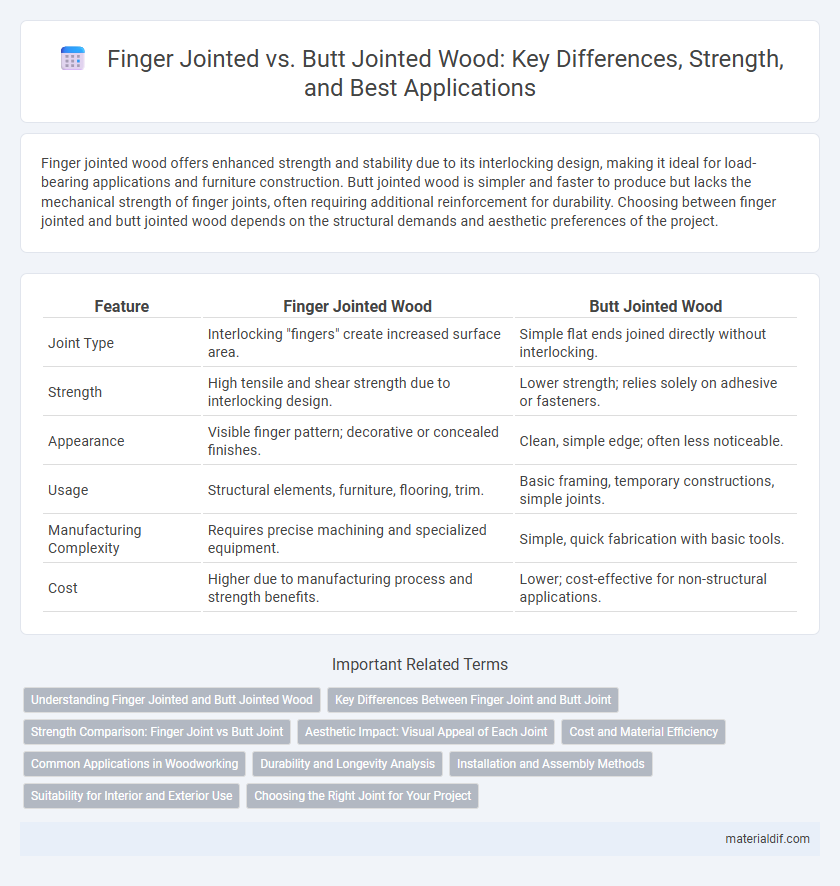

Finger jointed wood offers enhanced strength and stability due to its interlocking design, making it ideal for load-bearing applications and furniture construction. Butt jointed wood is simpler and faster to produce but lacks the mechanical strength of finger joints, often requiring additional reinforcement for durability. Choosing between finger jointed and butt jointed wood depends on the structural demands and aesthetic preferences of the project.

Table of Comparison

| Feature | Finger Jointed Wood | Butt Jointed Wood |

|---|---|---|

| Joint Type | Interlocking "fingers" create increased surface area. | Simple flat ends joined directly without interlocking. |

| Strength | High tensile and shear strength due to interlocking design. | Lower strength; relies solely on adhesive or fasteners. |

| Appearance | Visible finger pattern; decorative or concealed finishes. | Clean, simple edge; often less noticeable. |

| Usage | Structural elements, furniture, flooring, trim. | Basic framing, temporary constructions, simple joints. |

| Manufacturing Complexity | Requires precise machining and specialized equipment. | Simple, quick fabrication with basic tools. |

| Cost | Higher due to manufacturing process and strength benefits. | Lower; cost-effective for non-structural applications. |

Understanding Finger Jointed and Butt Jointed Wood

Finger jointed wood features interlocking, comb-like cuts that increase surface area for stronger adhesive bonding, enhancing durability and stability in woodworking applications. Butt jointed wood involves simply joining two pieces end-to-end without interlocking, resulting in a weaker connection that relies solely on glue or mechanical fasteners. This structural difference makes finger jointed wood preferable for load-bearing and precision assemblies, while butt joints are often used in less stressed, temporary, or cost-sensitive projects.

Key Differences Between Finger Joint and Butt Joint

Finger joints create a stronger bond by interlocking multiple fingers of wood, increasing surface area for glue and enhancing joint durability in woodwork. Butt joints involve simply joining two wood pieces end-to-end, relying solely on adhesive or mechanical fasteners, resulting in a weaker connection. Finger jointed wood is preferred for structural applications due to its enhanced strength, while butt joints are commonly used for simpler, non-load-bearing projects.

Strength Comparison: Finger Joint vs Butt Joint

Finger joints provide superior strength compared to butt joints due to their interlocking design, which increases the surface area for adhesive application and distributes stress more evenly across the joint. Butt joints rely solely on end-to-end adhesion, making them more prone to failure under load or tension. The enhanced mechanical interlock of finger joints results in greater resistance to bending and shear forces, making them ideal for structural woodworking applications.

Aesthetic Impact: Visual Appeal of Each Joint

Finger jointed wood features interlocking rectangular "fingers" that create a distinctive, repeating pattern, enhancing its visual complexity and making it ideal for decorative applications. Butt jointed wood presents a simple, flat surface where two pieces meet end-to-end, offering a cleaner, minimalist appearance but often requiring additional finishing to mask seams. The choice between finger and butt joints significantly influences the aesthetic appeal, with finger joints adding texture and character while butt joints emphasize subtlety and uniformity.

Cost and Material Efficiency

Finger jointed wood offers superior material efficiency by joining smaller offcuts into longer, usable pieces, reducing waste and maximizing lumber utilization. Though the manufacturing process is more complex and costly than butt jointed wood, finger joints provide enhanced strength and durability, often justifying the higher initial expense. Butt joints are simpler and cheaper to produce but typically result in weaker connections and more material waste due to shorter usable lengths.

Common Applications in Woodworking

Finger jointed wood is commonly used in furniture making, cabinetry, and molding due to its enhanced strength and seamless appearance. Butt jointed wood is typically found in simple frame construction, rough carpentry, and temporary fixtures where ease of assembly is prioritized over joint strength. Choosing between finger and butt joints depends on the structural requirements and aesthetic goals of the woodworking project.

Durability and Longevity Analysis

Finger jointed wood offers superior durability and longevity compared to butt jointed wood due to its interlocking design, which distributes stress evenly and reduces the risk of splitting. The increased surface area of the finger joints enhances adhesive bonding strength, resulting in a more stable and resilient structure under varying environmental conditions. Butt joints rely heavily on surface adhesives alone, making them more prone to failure and reducing the overall lifespan of wood assemblies.

Installation and Assembly Methods

Finger jointed wood panels provide enhanced alignment through interlocking profiles, which facilitate precise assembly and reduce gaps during installation. Butt jointed wood involves simply butting two flat edges together, requiring additional mechanical fasteners or adhesives to ensure structural stability. The finger joint method demands more intricate machinery and time but results in stronger, more uniform joints that improve overall wood panel performance.

Suitability for Interior and Exterior Use

Finger jointed wood offers superior strength and stability due to its interlocking pattern, making it highly suitable for interior applications where durability and aesthetic appeal are essential. Butt jointed wood, being simpler and less structurally sound, is typically recommended for interior uses only, as it lacks the resilience needed to withstand exterior weather conditions. Exterior environments benefit from finger jointed wood combined with proper sealing, ensuring enhanced resistance to moisture and temperature fluctuations.

Choosing the Right Joint for Your Project

Finger jointed wood offers superior strength and stability by interlocking multiple finger-like projections, making it ideal for load-bearing or long-span projects. Butt jointed wood, which involves simply joining two flat surfaces, is quicker to assemble but less durable and better suited for non-structural or decorative applications. Selecting the right joint depends on the project's structural requirements, desired aesthetics, and budget constraints.

Finger Jointed vs Butt Jointed Infographic

materialdif.com

materialdif.com