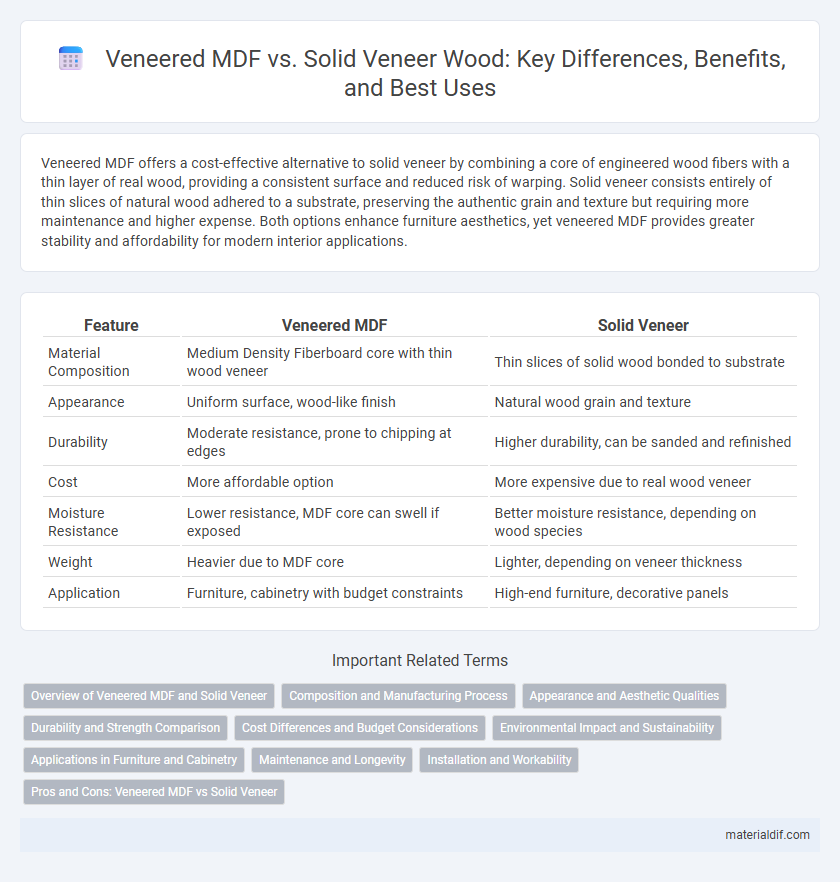

Veneered MDF offers a cost-effective alternative to solid veneer by combining a core of engineered wood fibers with a thin layer of real wood, providing a consistent surface and reduced risk of warping. Solid veneer consists entirely of thin slices of natural wood adhered to a substrate, preserving the authentic grain and texture but requiring more maintenance and higher expense. Both options enhance furniture aesthetics, yet veneered MDF provides greater stability and affordability for modern interior applications.

Table of Comparison

| Feature | Veneered MDF | Solid Veneer |

|---|---|---|

| Material Composition | Medium Density Fiberboard core with thin wood veneer | Thin slices of solid wood bonded to substrate |

| Appearance | Uniform surface, wood-like finish | Natural wood grain and texture |

| Durability | Moderate resistance, prone to chipping at edges | Higher durability, can be sanded and refinished |

| Cost | More affordable option | More expensive due to real wood veneer |

| Moisture Resistance | Lower resistance, MDF core can swell if exposed | Better moisture resistance, depending on wood species |

| Weight | Heavier due to MDF core | Lighter, depending on veneer thickness |

| Application | Furniture, cabinetry with budget constraints | High-end furniture, decorative panels |

Overview of Veneered MDF and Solid Veneer

Veneered MDF consists of a core made from wood fibers bonded together with resin, topped with a thin layer of real wood veneer, offering cost-effective durability and a smooth, consistent surface. Solid veneer refers to thin slices of natural wood adhered to a substrate, providing the authentic look and texture of hardwood with greater visual depth and grain variation. Both materials enhance furniture and cabinetry aesthetics, but veneered MDF balances affordability and stability while solid veneer delivers superior natural appeal.

Composition and Manufacturing Process

Veneered MDF consists of engineered wood fibers compressed into panels with a thin layer of real wood veneer applied on top, offering uniformity and cost-efficiency. Solid veneer involves slicing or peeling logs directly from hardwood, resulting in natural grain patterns and greater durability but higher material costs. The manufacturing process of veneered MDF uses adhesives and high pressure to bond the veneer to the fiberboard, whereas solid veneer is processed through precise cutting and drying methods to preserve natural wood qualities.

Appearance and Aesthetic Qualities

Veneered MDF offers a consistent, smooth surface with uniform color and grain patterns, ideal for achieving a modern and flawless appearance. Solid veneer showcases natural variations in wood grain and texture, providing a more authentic, rich aesthetic that highlights the uniqueness of each piece. While veneered MDF excels in uniformity and cost-effectiveness, solid veneer delivers superior depth and warmth in visual appeal.

Durability and Strength Comparison

Veneered MDF offers a smooth surface with consistent strength but is generally less durable than solid veneer due to its engineered core, which can be prone to swelling under moisture exposure. Solid veneer, crafted from real wood layers, provides superior durability and strength, maintaining structural integrity and resistance to wear over time. For applications requiring robustness and longevity, solid veneer is often the preferred choice despite its higher cost and heavier weight.

Cost Differences and Budget Considerations

Veneered MDF offers a cost-effective alternative to solid veneer, significantly reducing expenses due to its composite core made from wood fibers bonded with resin. Solid veneer provides higher durability and natural grain patterns but demands a larger budget because of its premium wood material and labor-intensive production. Budget considerations favor veneered MDF for large-scale projects where aesthetics and cost balance are crucial, while solid veneer suits high-end applications demanding authentic wood appearance and longevity.

Environmental Impact and Sustainability

Veneered MDF typically has a lower environmental impact than solid veneer due to its efficient use of wood fibers and reduced demand for large logs, promoting sustainable forestry. The production of veneered MDF consumes less energy and results in less waste compared to harvesting and processing solid veneer sheets from whole trees. Sustainable certifications like FSC and PEFC are essential for both materials to ensure responsible sourcing and minimize deforestation.

Applications in Furniture and Cabinetry

Veneered MDF offers a smooth, stable surface ideal for intricate furniture designs and cabinetry, providing resistance to warping and a cost-effective alternative to solid veneer. Solid veneer, made from thin slices of natural wood, delivers authentic grain patterns and superior durability, preferred in high-end furniture and cabinetry requiring premium aesthetics. Both materials enhance the visual appeal of furniture but differ significantly in weight, finish options, and longevity depending on project requirements.

Maintenance and Longevity

Veneered MDF offers a more cost-effective solution with easier maintenance due to its smooth, sealed surface that resists warping and moisture damage, ensuring consistent durability over time. Solid veneer, crafted from natural hardwood layers, requires more careful maintenance to prevent cracking and fading but provides superior longevity and the opportunity for refinishing, which extends its lifespan significantly. Choosing between veneered MDF and solid veneer depends on balancing maintenance effort with long-term durability and aesthetic preservation in wood furnishings.

Installation and Workability

Veneered MDF offers easier installation due to its uniform, stable core, reducing the risk of warping and splitting during cutting or shaping compared to solid veneer, which requires careful handling to avoid damage. Solid veneer, made from natural wood layers, demands more precise craftsmanship and specialized tools to achieve clean edges and smooth finishes. Workability of veneered MDF is enhanced by its consistent density, allowing for straightforward routing, drilling, and sanding, while solid veneer may require additional preparation to prevent surface imperfections.

Pros and Cons: Veneered MDF vs Solid Veneer

Veneered MDF offers consistent surface smoothness and affordability, making it ideal for budget-conscious projects, while its engineered core provides stability but lacks the natural grain depth of solid veneer. Solid veneer delivers authentic wood aesthetics with unique grain patterns and superior durability, though it tends to be more expensive and susceptible to warping under moisture. Choosing between veneered MDF and solid veneer depends on balancing cost, appearance, and performance requirements for specific woodworking applications.

Veneered MDF vs Solid veneer Infographic

materialdif.com

materialdif.com