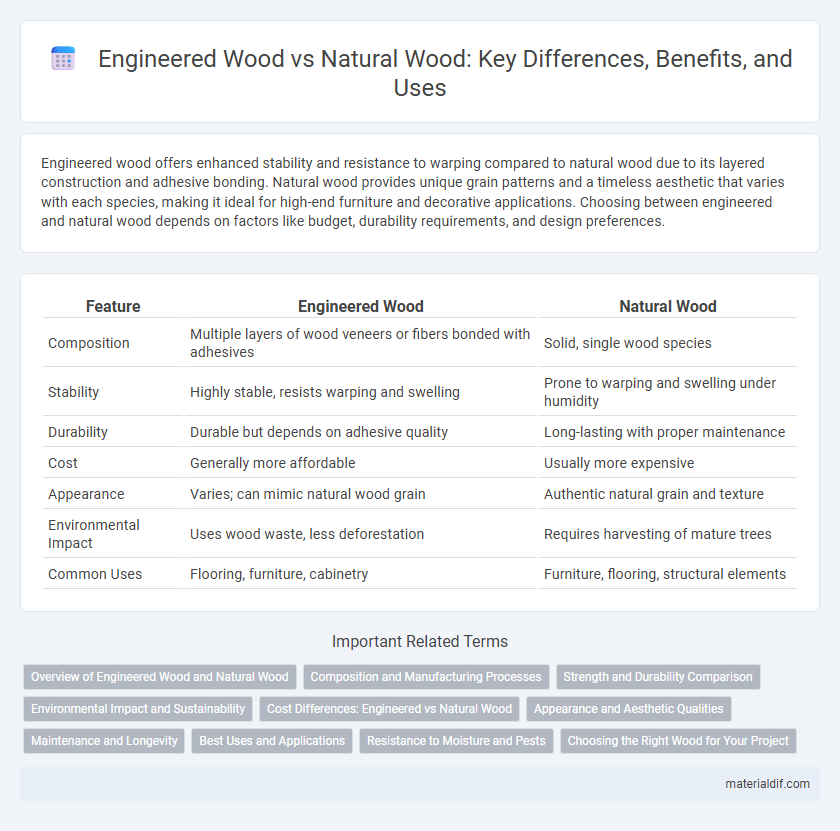

Engineered wood offers enhanced stability and resistance to warping compared to natural wood due to its layered construction and adhesive bonding. Natural wood provides unique grain patterns and a timeless aesthetic that varies with each species, making it ideal for high-end furniture and decorative applications. Choosing between engineered and natural wood depends on factors like budget, durability requirements, and design preferences.

Table of Comparison

| Feature | Engineered Wood | Natural Wood |

|---|---|---|

| Composition | Multiple layers of wood veneers or fibers bonded with adhesives | Solid, single wood species |

| Stability | Highly stable, resists warping and swelling | Prone to warping and swelling under humidity |

| Durability | Durable but depends on adhesive quality | Long-lasting with proper maintenance |

| Cost | Generally more affordable | Usually more expensive |

| Appearance | Varies; can mimic natural wood grain | Authentic natural grain and texture |

| Environmental Impact | Uses wood waste, less deforestation | Requires harvesting of mature trees |

| Common Uses | Flooring, furniture, cabinetry | Furniture, flooring, structural elements |

Overview of Engineered Wood and Natural Wood

Engineered wood consists of wood fibers, veneers, or strands bonded together with adhesives to create stable, uniform panels that resist warping and splitting. Natural wood is solid timber harvested directly from trees, known for its unique grain patterns and variable density influenced by species and growth conditions. Engineered wood offers enhanced dimensional stability and sustainability, while natural wood provides authentic aesthetics and long-lasting durability.

Composition and Manufacturing Processes

Engineered wood consists of wood veneers, fibers, or particles bonded together with adhesives under heat and pressure, resulting in products like plywood, MDF, and particleboard. Natural wood is derived directly from tree solid timber, retaining its cellular structure without modification or bonding. The manufacturing processes of engineered wood enhance strength, stability, and resistance to warping compared to the variable grain and moisture content in natural wood.

Strength and Durability Comparison

Engineered wood exhibits enhanced strength and durability due to its layered construction, which reduces the risk of warping and splitting compared to natural wood. Natural wood's strength varies significantly by species, with hardwoods like oak and maple offering high durability but remaining susceptible to moisture and insect damage. Engineered wood products such as plywood and laminated veneer lumber provide consistent performance and greater resistance to environmental changes, making them ideal for structural applications requiring long-term stability.

Environmental Impact and Sustainability

Engineered wood utilizes wood fibers and adhesives from multiple sources, reducing the need to harvest old-growth forests and lowering deforestation rates compared to natural wood. Its production often incorporates recycled materials and maximizes the use of smaller, fast-growing trees, enhancing sustainability by minimizing waste and promoting forest regeneration. Natural wood, while biodegradable and renewable, can contribute to habitat loss and carbon emissions if not sourced from responsibly managed forests.

Cost Differences: Engineered vs Natural Wood

Engineered wood typically costs less than natural wood due to its manufacturing process, which uses wood fibers, veneers, and adhesives to create stable, uniform panels. Natural wood's price varies widely depending on species, grade, and availability, often making it more expensive, especially for hardwoods like oak or walnut. The cost-effectiveness of engineered wood makes it a popular choice for flooring and cabinetry, while natural wood remains preferred for high-end furniture and detailed craftsmanship.

Appearance and Aesthetic Qualities

Engineered wood offers a consistent appearance with uniform grain patterns and color tones, making it ideal for modern, sleek designs. Natural wood displays unique variations in grain, knots, and color, providing a rich, organic aesthetic that enhances rustic and traditional interiors. The choice between engineered and natural wood impacts the visual warmth and character of furniture and flooring projects.

Maintenance and Longevity

Engineered wood offers enhanced durability and lower maintenance requirements compared to natural wood, thanks to its layered construction that resists warping and moisture damage. Natural wood, while aesthetically pleasing, often demands regular sealing, polishing, and protection against pests to maintain longevity. Proper care can extend the lifespan of both materials, but engineered wood typically provides a longer-lasting, more resilient option for high-traffic or moisture-prone environments.

Best Uses and Applications

Engineered wood offers superior stability and resistance to warping, making it ideal for flooring, cabinetry, and furniture in environments with fluctuating humidity. Natural wood provides unmatched aesthetic appeal and strength, preferred for structural beams, outdoor decking, and fine woodworking projects where natural grain and durability are essential. Both materials serve unique purposes, with engineered wood excelling in controlled applications and natural wood favored for traditional craftsmanship and high-stress structural uses.

Resistance to Moisture and Pests

Engineered wood exhibits superior resistance to moisture and pests compared to natural wood due to its composite layers and resin adhesives, which create a more stable and less porous material. Natural wood, being an organic and porous material, is more susceptible to water absorption, leading to swelling, warping, and increased vulnerability to wood-boring insects and fungal decay. Products like plywood and MDF in engineered wood offer enhanced durability in humid environments, making them preferable for construction in moisture-prone areas.

Choosing the Right Wood for Your Project

Selecting the right wood for your project requires understanding the key differences between engineered wood and natural wood. Engineered wood offers enhanced stability, resistance to warping, and cost-effectiveness, making it ideal for areas with varying humidity and budget constraints. Natural wood provides superior aesthetic appeal, durability, and unique grain patterns, perfect for high-end furniture and traditional craftsmanship.

Engineered Wood vs Natural Wood Infographic

materialdif.com

materialdif.com