Laminated wood offers enhanced stability and resistance to warping compared to solid wood due to its layered construction bonded with adhesives. Solid wood provides natural beauty, unique grain patterns, and durability but can be prone to expansion and contraction with humidity changes. Choosing between laminated and solid wood depends on the desired aesthetics, budget, and application requirements.

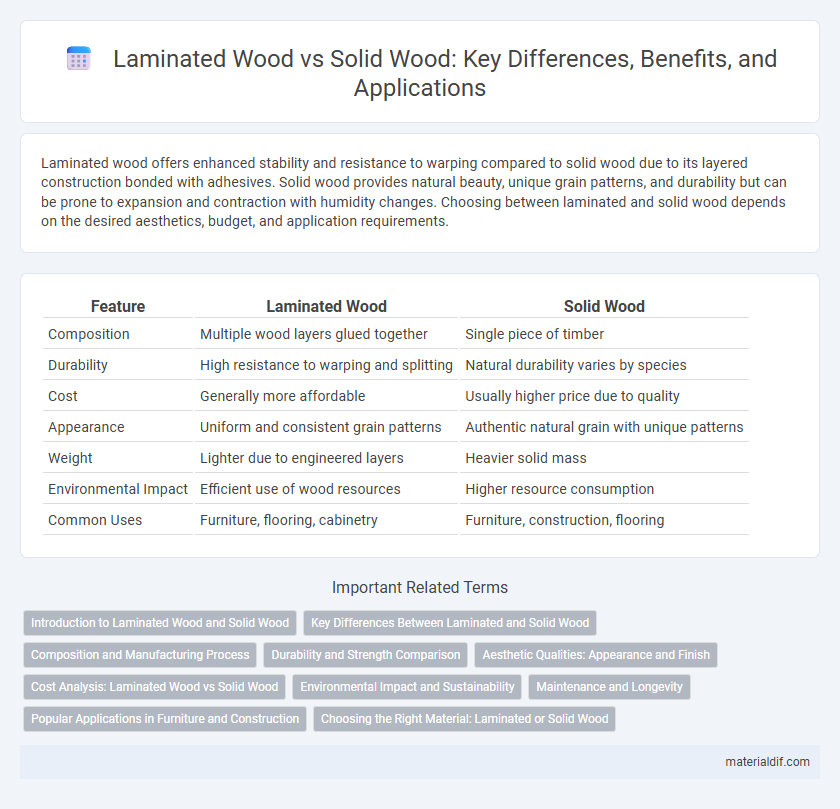

Table of Comparison

| Feature | Laminated Wood | Solid Wood |

|---|---|---|

| Composition | Multiple wood layers glued together | Single piece of timber |

| Durability | High resistance to warping and splitting | Natural durability varies by species |

| Cost | Generally more affordable | Usually higher price due to quality |

| Appearance | Uniform and consistent grain patterns | Authentic natural grain with unique patterns |

| Weight | Lighter due to engineered layers | Heavier solid mass |

| Environmental Impact | Efficient use of wood resources | Higher resource consumption |

| Common Uses | Furniture, flooring, cabinetry | Furniture, construction, flooring |

Introduction to Laminated Wood and Solid Wood

Laminated wood consists of multiple layers of wood veneers bonded with strong adhesives, providing enhanced strength, stability, and resistance to warping compared to solid wood. Solid wood is crafted from a single piece of natural timber, offering unique grain patterns and natural aesthetics, but it can be prone to expansion and contraction due to moisture changes. Both laminated and solid wood serve distinct purposes in construction and furniture making, with laminated wood favored for structural applications and solid wood prized for its classic appearance.

Key Differences Between Laminated and Solid Wood

Laminated wood consists of multiple layers of wood glued together, offering enhanced stability and resistance to warping compared to solid wood, which is a single piece of timber. Solid wood tends to have a richer natural grain and can be sanded and refinished multiple times, while laminated wood provides cost efficiency and improved structural strength. Moisture resistance is higher in laminated wood due to its engineered construction, making it suitable for environments where solid wood might degrade.

Composition and Manufacturing Process

Laminated wood, also known as engineered wood, consists of multiple layers of thin wood veneers or fibers bonded together under heat and pressure using strong adhesives, enhancing strength and stability compared to solid wood. Solid wood is cut directly from harvested logs and retains the natural grain and imperfections of the tree, offering uniform density but less resistance to warping and splitting. The manufacturing process of laminated wood allows for more efficient use of raw materials and greater customization in thickness and size, unlike the solid wood process which is limited by the dimensions of the original timber.

Durability and Strength Comparison

Laminated wood consists of multiple layers of wood glued together, providing enhanced strength and resistance to warping compared to solid wood. Solid wood, made from a single piece of timber, offers natural durability but can be more susceptible to cracking and deformation under extreme conditions. Laminated wood typically outperforms solid wood in load-bearing applications due to its engineered stability and uniform strength distribution.

Aesthetic Qualities: Appearance and Finish

Laminated wood offers a consistent and smooth appearance with minimal knots or imperfections, making it ideal for modern, sleek designs. Solid wood displays natural grain patterns and unique textures that enhance rustic and traditional aesthetics, providing a rich, organic finish. Both materials accept stains and finishes differently, with laminated wood allowing for uniform color application and solid wood showcasing varied tones and natural character.

Cost Analysis: Laminated Wood vs Solid Wood

Laminated wood typically costs less than solid wood due to its efficient manufacturing process, which uses smaller wood pieces bonded together, optimizing material usage and reducing waste. Solid wood is pricier because it requires cutting from large, natural logs with higher-quality, defect-free segments, leading to greater raw material costs and labor-intensive milling. When considering long-term value, laminated wood offers better dimensional stability and reduced maintenance expenses, while solid wood may incur higher repair costs due to susceptibility to warping and cracking.

Environmental Impact and Sustainability

Laminated wood typically uses smaller wood pieces and engineered adhesives, allowing for more efficient use of raw materials and reducing deforestation compared to solid wood, which requires larger, often older trees. The manufacturing process of laminated wood can be more energy-intensive, but its ability to utilize fast-growing species enhances sustainability by preserving natural forests. Solid wood is biodegradable and carbon-sequestering, yet its harvesting can lead to habitat loss and slower forest regeneration, impacting long-term environmental balance.

Maintenance and Longevity

Laminated wood requires less maintenance than solid wood due to its resistance to warping and cracking, making it ideal for high-humidity environments. Solid wood offers superior durability and can last for decades with proper care, including regular sealing and refinishing to prevent moisture damage. Both materials benefit from routine cleaning, but solid wood demands more frequent upkeep to maintain its natural appearance and structural integrity.

Popular Applications in Furniture and Construction

Laminated wood offers superior strength and dimensional stability, making it ideal for large furniture pieces like dining tables and construction elements such as beams and flooring. Solid wood is prized for its natural beauty and durability, commonly used in high-end cabinetry, doors, and decorative furniture where aesthetics are paramount. Both materials play crucial roles in construction and furniture design, with laminated wood favored for structural applications and solid wood for craftsmanship and finishing details.

Choosing the Right Material: Laminated or Solid Wood

Laminated wood offers greater stability and resistance to warping due to its layered construction, making it ideal for furniture exposed to moisture or temperature fluctuations. Solid wood provides natural durability, unique grain patterns, and can be refinished multiple times, which appeals to those prioritizing longevity and aesthetic authenticity. Selecting the right material depends on balancing factors like budget, intended use, environmental conditions, and desired maintenance levels in your woodworking project.

Laminated Wood vs Solid Wood Infographic

materialdif.com

materialdif.com