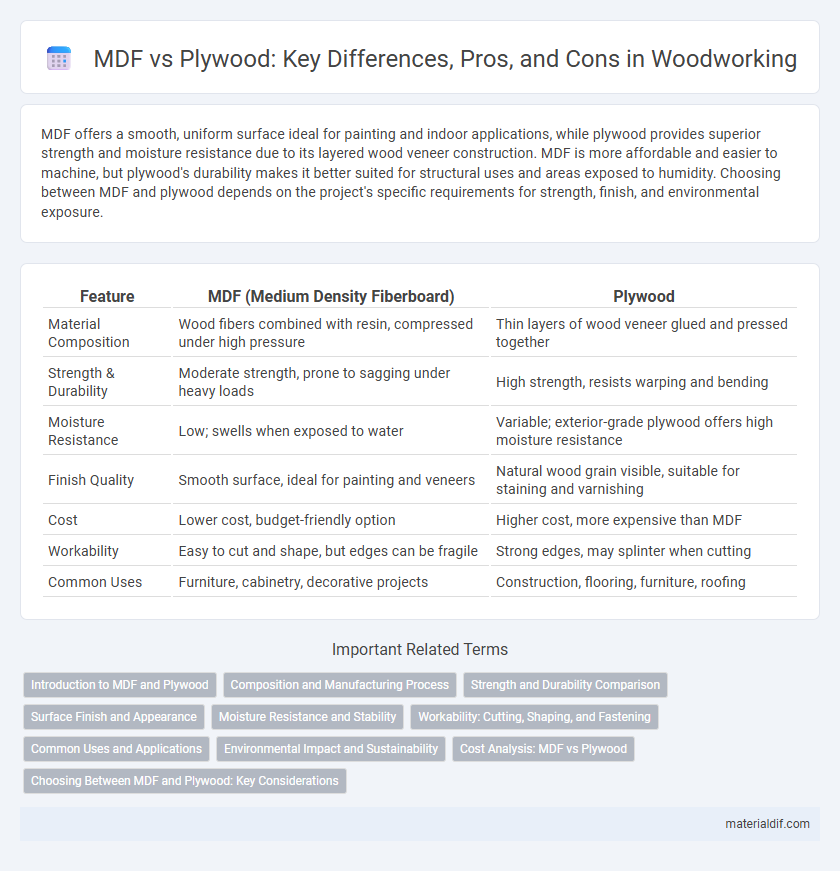

MDF offers a smooth, uniform surface ideal for painting and indoor applications, while plywood provides superior strength and moisture resistance due to its layered wood veneer construction. MDF is more affordable and easier to machine, but plywood's durability makes it better suited for structural uses and areas exposed to humidity. Choosing between MDF and plywood depends on the project's specific requirements for strength, finish, and environmental exposure.

Table of Comparison

| Feature | MDF (Medium Density Fiberboard) | Plywood |

|---|---|---|

| Material Composition | Wood fibers combined with resin, compressed under high pressure | Thin layers of wood veneer glued and pressed together |

| Strength & Durability | Moderate strength, prone to sagging under heavy loads | High strength, resists warping and bending |

| Moisture Resistance | Low; swells when exposed to water | Variable; exterior-grade plywood offers high moisture resistance |

| Finish Quality | Smooth surface, ideal for painting and veneers | Natural wood grain visible, suitable for staining and varnishing |

| Cost | Lower cost, budget-friendly option | Higher cost, more expensive than MDF |

| Workability | Easy to cut and shape, but edges can be fragile | Strong edges, may splinter when cutting |

| Common Uses | Furniture, cabinetry, decorative projects | Construction, flooring, furniture, roofing |

Introduction to MDF and Plywood

MDF (Medium-Density Fiberboard) is an engineered wood product made from wood fibers, wax, and resin compressed under high pressure, offering a smooth surface ideal for painting and indoor use. Plywood consists of thin layers of wood veneer glued together with the grain of adjacent layers rotated, providing superior strength, durability, and resistance to warping, making it suitable for structural and exterior applications. Both materials serve different purposes in woodworking, with MDF favored for cabinetry and furniture while plywood is preferred for construction and heavy-duty projects.

Composition and Manufacturing Process

MDF (Medium Density Fiberboard) is engineered from wood fibers combined with wax and resin, which are compressed under high heat and pressure to form dense, smooth panels ideal for detailed finishes. Plywood consists of thin layers of wood veneer glued together with the grain of each layer oriented perpendicular to adjacent layers, creating a strong, flexible panel with excellent resistance to warping. The manufacturing process of MDF involves breaking down wood into fibers, while plywood retains the natural wood grain structure through lamination, affecting their respective strength and application in woodworking projects.

Strength and Durability Comparison

MDF (Medium Density Fiberboard) is engineered from compressed wood fibers, offering a smooth surface ideal for painting but generally has lower resistance to moisture and impact compared to plywood. Plywood consists of multiple layers of wood veneers glued together with alternating grain directions, enhancing its overall strength, resistance to warping, and durability in structural applications. For projects requiring high load-bearing capacity and longevity, plywood outperforms MDF, especially in environments exposed to humidity and mechanical stress.

Surface Finish and Appearance

MDF offers a smooth, uniform surface ideal for painting and detailed finishes, while plywood showcases a natural wood grain that enhances aesthetic appeal when stained or varnished. The lack of knots and voids in MDF ensures a consistent texture, making it preferable for sleek, modern designs. Plywood's layered construction provides a more textured and authentic wood look, favored in visible applications where natural beauty matters.

Moisture Resistance and Stability

MDF (Medium Density Fiberboard) offers consistent density but is highly susceptible to moisture damage, leading to swelling and warping when exposed to water. Plywood, composed of multiple wood veneers, provides superior moisture resistance and dimensional stability due to its cross-grain construction, making it more suitable for humid environments. For applications requiring enhanced durability against moisture, exterior-grade plywood or moisture-resistant treated MDF variants are preferable choices.

Workability: Cutting, Shaping, and Fastening

MDF offers exceptional workability with smooth edges and uniform density, making it easy to cut and shape without splintering, while plywood's layered grain provides superior strength but can cause chipping during cutting. Fastening MDF requires pre-drilling to avoid splitting, whereas plywood accepts screws and nails more readily due to its natural wood grain structure. Both materials serve distinct purposes depending on the precision and durability required in woodworking projects.

Common Uses and Applications

MDF is commonly used for interior applications such as furniture, cabinetry, and decorative moldings due to its smooth surface and ease of painting. Plywood is favored for structural uses like flooring, roofing, and wall sheathing because of its higher strength and moisture resistance. Both materials serve distinct purposes in construction and woodworking, with MDF excelling in precision work and plywood offering durability in load-bearing environments.

Environmental Impact and Sustainability

MDF (Medium Density Fiberboard) production relies heavily on wood fibers bonded with synthetic resins, often containing formaldehyde, leading to higher emissions and challenges in recycling compared to plywood. Plywood, constructed from thin layers of wood veneer, typically generates less waste and has a longer lifespan, contributing to a lower overall environmental footprint. Sustainable sourcing certifications like FSC and the use of formaldehyde-free adhesives improve the eco-friendliness of both materials, but plywood generally offers better biodegradability and recyclability.

Cost Analysis: MDF vs Plywood

MDF (Medium-Density Fiberboard) typically costs less than plywood due to its manufacturing process using wood fibers and resin, resulting in a more affordable price per sheet. Plywood, made from thin layers of wood veneer, tends to be more expensive but offers greater strength and durability, which can justify its higher initial cost for structural applications. Considering long-term use, MDF is ideal for budget-friendly, interior projects, while plywood provides better value in load-bearing or moisture-prone environments.

Choosing Between MDF and Plywood: Key Considerations

MDF (Medium Density Fiberboard) offers a smooth surface ideal for detailed painting and indoor projects, while plywood provides superior strength and moisture resistance, making it suitable for structural applications. Consider factors such as durability, exposure to humidity, and budget, as MDF is generally more affordable but less durable when wet compared to plywood. Selecting between MDF and plywood depends on the specific requirements of the project, including load-bearing needs and environmental conditions.

MDF vs Plywood Infographic

materialdif.com

materialdif.com