Rotary cut veneer is produced by peeling a log in a continuous sheet, resulting in a broad, bold grain pattern ideal for plywood cores and decorative surfaces. Sliced cut veneer is created by slicing thin sheets from a log, offering more intricate and varied grain patterns that highlight the wood's natural character. Choosing between rotary and sliced cut veneers depends on the desired aesthetic and application, with rotary providing uniformity and sliced emphasizing detail.

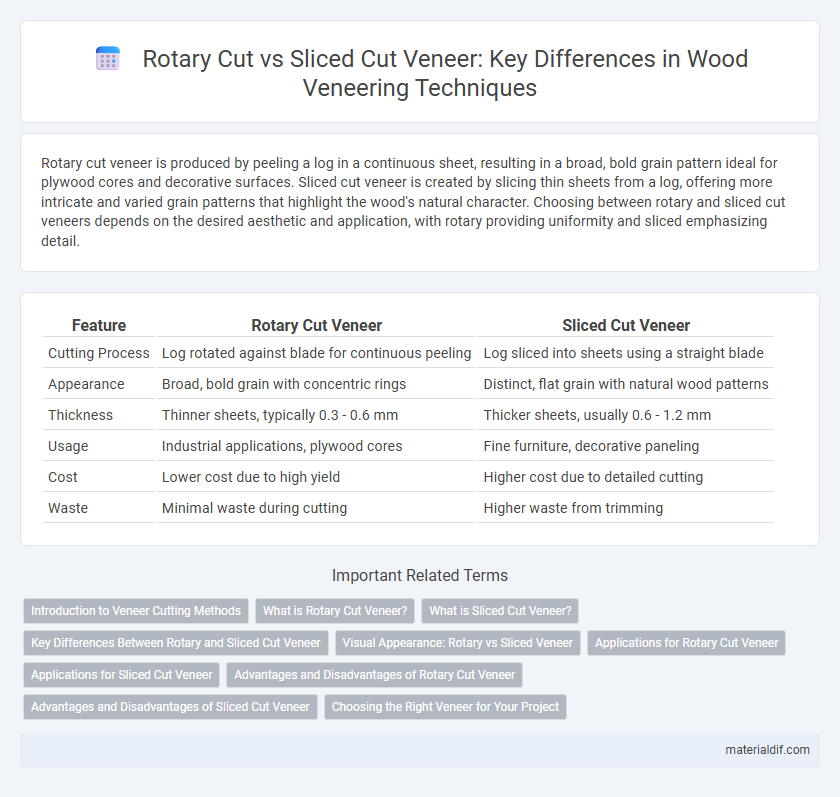

Table of Comparison

| Feature | Rotary Cut Veneer | Sliced Cut Veneer |

|---|---|---|

| Cutting Process | Log rotated against blade for continuous peeling | Log sliced into sheets using a straight blade |

| Appearance | Broad, bold grain with concentric rings | Distinct, flat grain with natural wood patterns |

| Thickness | Thinner sheets, typically 0.3 - 0.6 mm | Thicker sheets, usually 0.6 - 1.2 mm |

| Usage | Industrial applications, plywood cores | Fine furniture, decorative paneling |

| Cost | Lower cost due to high yield | Higher cost due to detailed cutting |

| Waste | Minimal waste during cutting | Higher waste from trimming |

Introduction to Veneer Cutting Methods

Rotary cut veneer involves peeling a log in a continuous spiral, producing wide sheets with bold, open grain patterns ideal for plywood and decorative surfaces. Sliced cut veneer is created by slicing a log tangentially, resulting in narrower sheets with more uniform, linear grain patterns favored for fine furniture and cabinetry. Both methods optimize wood utilization but differ in appearance, texture, and application based on the cutting technique.

What is Rotary Cut Veneer?

Rotary cut veneer is produced by peeling a log in a continuous rotational motion, resulting in wide sheets of wood veneer with a distinctive grain pattern. This method reveals the entire circumference of the log, creating bold and varied grain appearances ideal for plywood and paneling. Rotary cut veneer is often preferred for its cost-effectiveness and maximum material yield compared to sliced cut veneer.

What is Sliced Cut Veneer?

Sliced cut veneer is a thin layer of wood produced by slicing a log tangentially, resulting in a flatter, more uniform grain pattern compared to rotary cut veneer. This method preserves the natural texture and appearance of the wood, making it ideal for high-quality furniture and cabinetry. Sliced veneer often showcases distinct grain variations and intricate details unique to each tree species.

Key Differences Between Rotary and Sliced Cut Veneer

Rotary cut veneer is produced by peeling the log in a continuous rotation, yielding wide sheets with a bold, open grain pattern ideal for plywood cores and decorative surfaces. Sliced cut veneer involves cutting the log into thin sheets with a straight or slightly curved slicing motion, which preserves the natural grain patterns and textures, making it more suitable for furniture and fine cabinetry. The rotary method maximizes yield and efficiency, while sliced veneer emphasizes aesthetic appeal and grain detail.

Visual Appearance: Rotary vs Sliced Veneer

Rotary cut veneer displays a broad, bold grain pattern with a more uniform and circular grain appearance due to the log being peeled in a continuous rotation. Sliced cut veneer reveals more distinct and varied grain patterns, characterized by cathedral or flame figures, providing a more textured and intricate visual appearance. The choice between rotary and sliced veneer impacts the aesthetic of wood surfaces, with rotary offering a more consistent look and sliced delivering detailed, natural wood character.

Applications for Rotary Cut Veneer

Rotary cut veneer is predominantly used in manufacturing plywood, furniture, and cabinetry due to its ability to produce large, continuous sheets with a strong, consistent grain pattern. This veneer type is ideal for applications requiring high surface coverage and cost-efficiency, such as wall paneling and flooring underlayment. Rotary cut veneer's unique grain characteristics enhance structural stability, making it preferred in construction and industrial wood products.

Applications for Sliced Cut Veneer

Sliced cut veneer is widely used in high-end furniture, cabinetry, and architectural paneling due to its consistent grain patterns and smooth surface finish. This veneer type showcases attractive, natural wood figures, making it ideal for decorative applications where visual appeal is paramount. Its uniform appearance allows for easier matching across large surfaces, enhancing aesthetic continuity in interiors.

Advantages and Disadvantages of Rotary Cut Veneer

Rotary cut veneer offers the advantage of maximizing timber yield by peeling entire log circumferences into continuous sheets, making it cost-effective and ideal for plywood production. The process reveals broad, bold grain patterns that are less uniform but valued for natural variation and rustic appeal. However, rotary cut veneer tends to have lower stability and less refined aesthetics compared to sliced cut veneer, which can limit its use in fine furniture or decorative panels.

Advantages and Disadvantages of Sliced Cut Veneer

Sliced cut veneer offers a more uniform and consistent grain pattern compared to rotary cut veneer, enhancing its aesthetic appeal in fine woodworking and furniture making. This method produces a smoother surface, which is easier to finish and stain, but it tends to waste more wood and is less efficient than rotary cutting. While sliced veneers excel in visual quality, they can be more expensive and have less flexibility in size and shape than rotary cut veneers.

Choosing the Right Veneer for Your Project

Rotary cut veneer offers broad, continuous grain patterns ideal for large surfaces and a natural appearance, making it suitable for cabinetry and paneling. Sliced cut veneer, produced by slicing logs tangentially, reveals intricate, diverse grain figures favored in furniture and decorative applications requiring detailed aesthetics. Selecting the right veneer depends on the project's design goals, durability needs, and visual impact, balancing cost-efficiency with desired wood grain characteristics.

Rotary Cut Veneer vs Sliced Cut Veneer Infographic

materialdif.com

materialdif.com