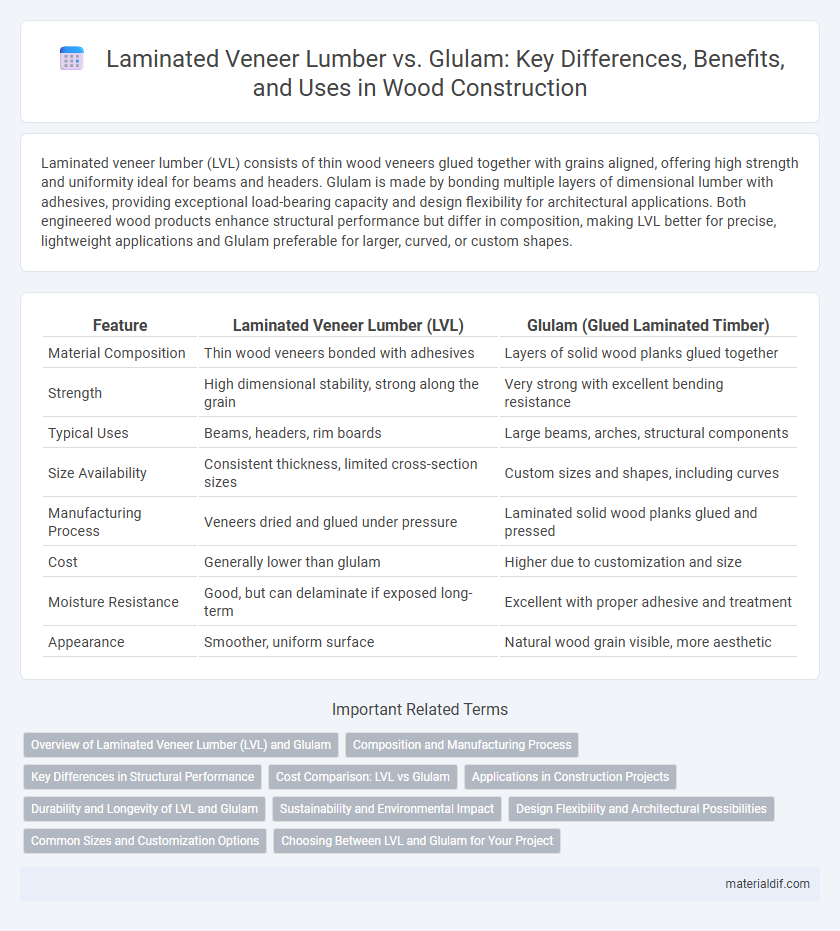

Laminated veneer lumber (LVL) consists of thin wood veneers glued together with grains aligned, offering high strength and uniformity ideal for beams and headers. Glulam is made by bonding multiple layers of dimensional lumber with adhesives, providing exceptional load-bearing capacity and design flexibility for architectural applications. Both engineered wood products enhance structural performance but differ in composition, making LVL better for precise, lightweight applications and Glulam preferable for larger, curved, or custom shapes.

Table of Comparison

| Feature | Laminated Veneer Lumber (LVL) | Glulam (Glued Laminated Timber) |

|---|---|---|

| Material Composition | Thin wood veneers bonded with adhesives | Layers of solid wood planks glued together |

| Strength | High dimensional stability, strong along the grain | Very strong with excellent bending resistance |

| Typical Uses | Beams, headers, rim boards | Large beams, arches, structural components |

| Size Availability | Consistent thickness, limited cross-section sizes | Custom sizes and shapes, including curves |

| Manufacturing Process | Veneers dried and glued under pressure | Laminated solid wood planks glued and pressed |

| Cost | Generally lower than glulam | Higher due to customization and size |

| Moisture Resistance | Good, but can delaminate if exposed long-term | Excellent with proper adhesive and treatment |

| Appearance | Smoother, uniform surface | Natural wood grain visible, more aesthetic |

Overview of Laminated Veneer Lumber (LVL) and Glulam

Laminated Veneer Lumber (LVL) is an engineered wood product made by bonding thin wood veneers under heat and pressure, offering high strength and uniformity for beams, headers, and rim boards. Glulam, or glued laminated timber, consists of multiple layers of dimensioned lumber bonded with durable adhesives, providing versatility in structural applications like beams, columns, and arches with enhanced load-bearing capacity. Both LVL and Glulam are favored for their dimensional stability, sustainability, and ability to replace traditional solid wood in construction projects.

Composition and Manufacturing Process

Laminated veneer lumber (LVL) is composed of thin wood veneers bonded together with adhesives under heat and pressure, creating a uniform, high-strength structural panel. Glulam, or glued laminated timber, consists of multiple layers of solid wood laminations glued face-to-face along their length, allowing for larger and more curved structural components. The LVL manufacturing process emphasizes veneer slicing and precise adhesive application for consistent thickness, while glulam involves gluing and clamping solid wood boards, often enabling customization in shape and sizes.

Key Differences in Structural Performance

Laminated Veneer Lumber (LVL) offers high uniformity and strength due to its thin wood veneers bonded under heat and pressure, resulting in excellent load-bearing capacity with minimal cross-grain weaknesses. Glulam, composed of multiple layers of dimensioned lumber glued together, provides superior dimensional stability and can be manufactured in large, curved shapes ideal for architectural applications requiring both strength and aesthetic appeal. LVL typically excels in consistent performance for straight beams, while Glulam is preferred for customized structural designs with enhanced bending strength and flexibility.

Cost Comparison: LVL vs Glulam

Laminated veneer lumber (LVL) generally costs less per linear foot compared to glulam due to its simpler manufacturing process and use of thin veneers rather than large laminations. LVL provides a cost-effective solution for structural applications requiring uniform strength and dimensional stability, making it ideal for budget-conscious building projects. Glulam, while more expensive, offers greater design flexibility and aesthetic appeal, justifying its higher price in specialized or architectural constructions.

Applications in Construction Projects

Laminated veneer lumber (LVL) is highly favored in construction projects requiring consistent strength and dimensional stability, such as beams, headers, and rim boards in residential and commercial buildings. Glulam, composed of multiple layers of timber bonded together, is preferred for large structural elements like arches, long-span beams, and complex architectural shapes due to its ability to support heavy loads and its aesthetic appeal. Both LVL and Glulam offer superior engineered wood solutions, but LVL excels in uniformity and precise applications, while Glulam provides versatility and strength in visually exposed structures.

Durability and Longevity of LVL and Glulam

Laminated veneer lumber (LVL) offers enhanced dimensional stability and resistance to warping, making it highly durable in various environmental conditions. Glulam beams exhibit exceptional strength and longevity due to their layered construction, which distributes loads evenly and resists deformation over time. Both LVL and Glulam demonstrate superior durability compared to traditional solid wood, with Glulam generally preferred for heavy structural applications requiring long-term performance.

Sustainability and Environmental Impact

Laminated veneer lumber (LVL) and Glulam both offer sustainable alternatives to traditional solid wood by maximizing wood resource efficiency through engineered layering techniques. LVL typically utilizes thin wood veneers bonded with adhesives, reducing waste and allowing for the use of fast-growing species, which lowers environmental impact and carbon footprint. Glulam's large structural beams can be made from smaller timber pieces, promoting reforestation and minimizing deforestation compared to solid sawn lumber, making both materials favorable for eco-conscious construction.

Design Flexibility and Architectural Possibilities

Laminated veneer lumber (LVL) offers superior design flexibility due to its uniform strength and dimensional stability, enabling the creation of slender, curved, and intricate shapes. Glulam beams allow for large-span structures and dramatic architectural forms with exposed wood aesthetics, often used in atriums and bridges. Both materials enhance architectural possibilities by combining structural efficiency with customizable appearance, but LVL excels in precision applications while glulam supports bold, load-bearing designs.

Common Sizes and Customization Options

Laminated veneer lumber (LVL) typically comes in standard thicknesses ranging from 1 3/4 inches to 3 1/2 inches, with widths up to 24 inches and lengths up to 60 feet, offering moderate customization mainly in length and thickness. Glulam beams are available in wider size ranges, often from 1 1/2 inches to 6 inches in thickness and widths exceeding 24 inches, with lengths commonly extending beyond 80 feet, allowing greater flexibility in shape and radius for architectural designs. Both LVL and Glulam can be tailored to meet specific load requirements, but Glulam provides more extensive curvature and dimensional variety due to its lamination and manufacturing process.

Choosing Between LVL and Glulam for Your Project

Laminated veneer lumber (LVL) offers high strength and uniformity from multiple thin wood veneers bonded under heat and pressure, making it ideal for long spans and heavy loads in structural framing. Glulam, composed of laminated dimensional lumber pieces glued together, provides greater design flexibility with curved shapes and large beam sizes, suitable for architectural applications requiring aesthetics and durability. Selecting LVL or Glulam depends on project requirements such as load capacity, span length, dimensional stability, and desired appearance, with LVL favored for straight, load-bearing components and Glulam preferred for customized, visually appealing structures.

Laminated veneer lumber vs Glulam Infographic

materialdif.com

materialdif.com