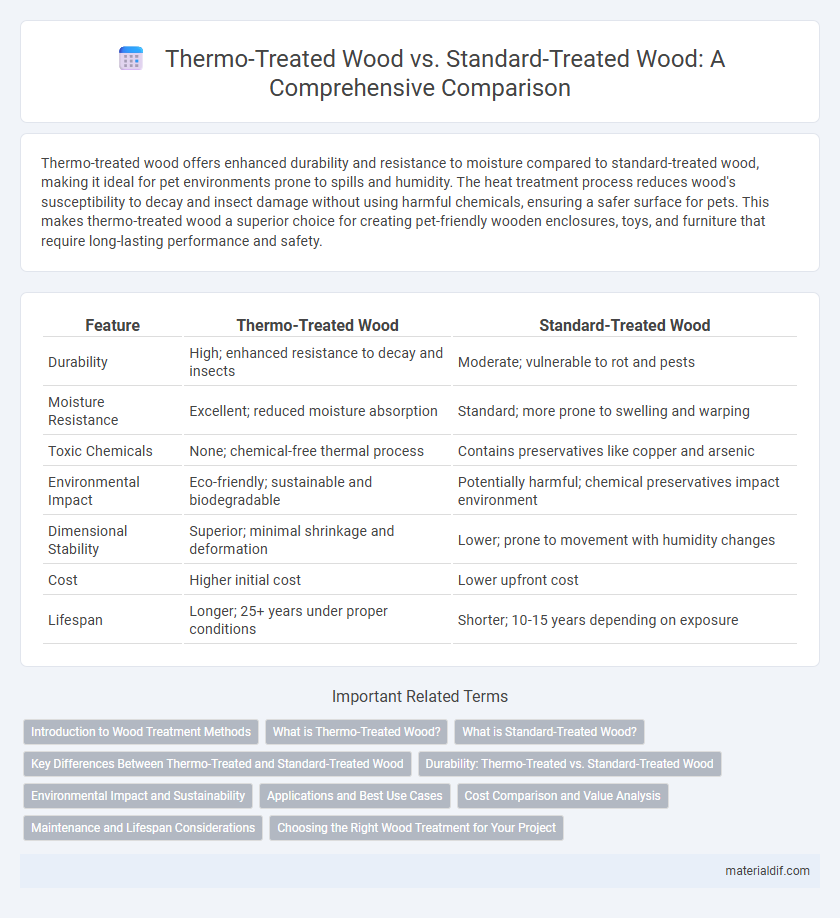

Thermo-treated wood offers enhanced durability and resistance to moisture compared to standard-treated wood, making it ideal for pet environments prone to spills and humidity. The heat treatment process reduces wood's susceptibility to decay and insect damage without using harmful chemicals, ensuring a safer surface for pets. This makes thermo-treated wood a superior choice for creating pet-friendly wooden enclosures, toys, and furniture that require long-lasting performance and safety.

Table of Comparison

| Feature | Thermo-Treated Wood | Standard-Treated Wood |

|---|---|---|

| Durability | High; enhanced resistance to decay and insects | Moderate; vulnerable to rot and pests |

| Moisture Resistance | Excellent; reduced moisture absorption | Standard; more prone to swelling and warping |

| Toxic Chemicals | None; chemical-free thermal process | Contains preservatives like copper and arsenic |

| Environmental Impact | Eco-friendly; sustainable and biodegradable | Potentially harmful; chemical preservatives impact environment |

| Dimensional Stability | Superior; minimal shrinkage and deformation | Lower; prone to movement with humidity changes |

| Cost | Higher initial cost | Lower upfront cost |

| Lifespan | Longer; 25+ years under proper conditions | Shorter; 10-15 years depending on exposure |

Introduction to Wood Treatment Methods

Thermo-treated wood undergoes a heat treatment process that enhances its durability, dimensional stability, and resistance to decay without the use of chemicals, distinguishing it from standard-treated wood which relies on chemical preservatives like copper-based compounds to prevent rot and insect damage. This thermal modification alters the wood's cellular structure, reducing moisture absorption and increasing its lifespan, making it particularly suitable for outdoor applications where environmental exposure is a concern. Standard chemical treatments are more common and cost-effective but may have environmental and health considerations that thermo-treated wood avoids due to its eco-friendly process.

What is Thermo-Treated Wood?

Thermo-treated wood is wood that has undergone a heat treatment process at temperatures between 160degC and 220degC, which alters its chemical and physical properties to enhance durability and stability. This process reduces the wood's moisture content, making it more resistant to decay, insects, and warping compared to standard-treated wood. Unlike conventional chemical treatments, thermo-treatment uses only heat and steam, resulting in an environmentally friendly alternative with improved dimensional stability and a darker, richer appearance.

What is Standard-Treated Wood?

Standard-treated wood refers to lumber that has been preserved using chemical preservatives like chromated copper arsenate (CCA) or alkaline copper quaternary (ACQ) to protect against decay, insects, and fungal growth. This treatment is applied under pressure to ensure deep penetration, enhancing the wood's durability for outdoor and structural uses. Unlike thermo-treated wood, standard-treated wood relies on chemical preservation rather than heat modification for its resistance properties.

Key Differences Between Thermo-Treated and Standard-Treated Wood

Thermo-treated wood undergoes a high-temperature process that enhances its durability, dimensional stability, and resistance to decay without chemical additives, unlike standard-treated wood, which relies on chemical preservatives such as copper azole or chromated copper arsenate. The heat treatment significantly reduces the wood's moisture content, resulting in improved resistance to warping and insect damage, whereas standard-treated wood maintains higher moisture levels and depends on chemicals for protection. Thermo-treated wood offers a more eco-friendly and chemical-free alternative with a natural appearance, while standard-treated wood typically exhibits a greenish or brown tint due to the preservatives.

Durability: Thermo-Treated vs. Standard-Treated Wood

Thermo-treated wood demonstrates superior durability compared to standard-treated wood due to its enhanced resistance to moisture, decay, and insect damage achieved through high-temperature processing. This thermal modification significantly increases dimensional stability and lifespan, making it ideal for outdoor applications and harsh environments. Standard-treated wood relies on chemical preservatives that may leach over time, reducing long-term effectiveness and structural integrity.

Environmental Impact and Sustainability

Thermo-treated wood undergoes a heat treatment process that reduces the need for chemical preservatives, significantly lowering its environmental impact compared to standard-treated wood, which relies on potentially harmful chemicals like chromated copper arsenate (CCA). The heat treatment enhances the wood's durability and resistance to decay while maintaining its biodegradability, making it a more sustainable option in construction and furniture production. Standard-treated wood, though effective for preservation, often introduces toxic substances into the environment and complicates recycling or disposal, impacting long-term sustainability.

Applications and Best Use Cases

Thermo-treated wood, enhanced through controlled heating, offers superior dimensional stability and resistance to decay, making it ideal for outdoor applications like decking, cladding, and garden furniture. Standard-treated wood, often chemically infused, provides cost-effective protection against insects and moisture, commonly used in structural framing and utility poles. Choosing between these depends on project exposure conditions and desired longevity, with thermo-treated wood favored for aesthetic outdoor uses and standard-treated wood suited for basic structural needs.

Cost Comparison and Value Analysis

Thermo-treated wood generally incurs higher upfront costs compared to standard-treated wood due to advanced heat treatment processes that enhance durability and resistance to decay. While standard-treated wood is more affordable initially, thermo-treated wood offers greater long-term value by reducing maintenance expenses and extending the lifespan of outdoor projects. The cost-benefit analysis favors thermo-treated wood for applications requiring superior performance and sustainability despite the increased initial investment.

Maintenance and Lifespan Considerations

Thermo-treated wood offers enhanced durability and resistance to decay compared to standard-treated wood, reducing the frequency of maintenance required over time. Its heat treatment process improves dimensional stability, minimizing warping and cracking, which extends the overall lifespan of the wood in outdoor applications. Standard-treated wood typically demands more frequent sealing or staining to protect against environmental damage, resulting in higher ongoing upkeep costs.

Choosing the Right Wood Treatment for Your Project

Thermo-treated wood undergoes a controlled heating process that enhances durability, stability, and resistance to decay without the use of chemicals, making it ideal for outdoor and eco-conscious projects. Standard-treated wood is typically infused with chemical preservatives to protect against insects and rot, offering a cost-effective solution for structural applications requiring long-term protection. Selecting the right wood treatment depends on project requirements such as environmental exposure, desired lifespan, and sustainability goals.

Thermo-Treated Wood vs Standard-Treated Wood Infographic

materialdif.com

materialdif.com