Kiln-dried wood undergoes a controlled heating process that rapidly removes moisture, resulting in a more stable and stronger material ideal for construction and furniture-making. Air-dried wood is dried naturally through exposure to air, which takes longer but is less energy-intensive and often preferred for traditional woodworking due to its slower, more even drying process. Choosing between kiln-dried and air-dried wood depends on project requirements, balancing speed, cost, and wood performance.

Table of Comparison

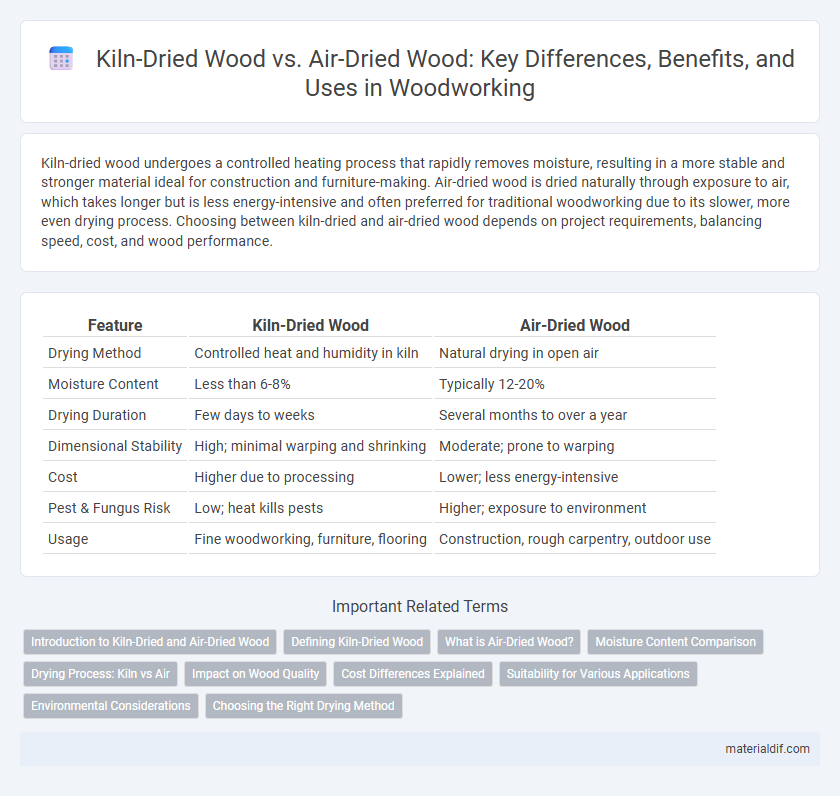

| Feature | Kiln-Dried Wood | Air-Dried Wood |

|---|---|---|

| Drying Method | Controlled heat and humidity in kiln | Natural drying in open air |

| Moisture Content | Less than 6-8% | Typically 12-20% |

| Drying Duration | Few days to weeks | Several months to over a year |

| Dimensional Stability | High; minimal warping and shrinking | Moderate; prone to warping |

| Cost | Higher due to processing | Lower; less energy-intensive |

| Pest & Fungus Risk | Low; heat kills pests | Higher; exposure to environment |

| Usage | Fine woodworking, furniture, flooring | Construction, rough carpentry, outdoor use |

Introduction to Kiln-Dried and Air-Dried Wood

Kiln-dried wood undergoes a controlled drying process in a kiln, reducing moisture content to 6-8%, which enhances stability and prevents warping. Air-dried wood dries naturally in open air, typically reaching moisture levels around 12-15%, depending on climate and drying time. Each method affects wood durability, weight, and suitability for specific construction or woodworking projects.

Defining Kiln-Dried Wood

Kiln-dried wood undergoes a controlled drying process in a temperature-regulated kiln to reduce moisture content to a specific level, often between 6% and 8%, ensuring enhanced stability and strength. This method accelerates drying time compared to traditional air drying, minimizing the risk of warping, cracking, and fungal growth. Kiln-dried wood is favored in construction and woodworking for its uniformity, improved durability, and suitability for indoor applications.

What is Air-Dried Wood?

Air-dried wood is lumber that has been naturally dried by stacking it in open-air environments, allowing moisture to evaporate over time, typically reaching a moisture content of 12-20%. This method relies on airflow, ambient temperature, and humidity, resulting in slower drying compared to kiln drying. Air-dried wood retains more natural moisture and can have a slightly higher risk of warping or insect infestation due to prolonged exposure to environmental conditions.

Moisture Content Comparison

Kiln-dried wood typically has a controlled moisture content of 6-8%, achieved through an accelerated drying process in a heated chamber, making it more stable and less prone to warping or shrinkage. Air-dried wood, on the other hand, naturally equilibrates to a moisture content of around 12-20%, depending on ambient humidity and drying time, which can result in higher variability and potential for movement. Understanding the moisture content differences between kiln-dried and air-dried wood is crucial for selecting the right material for construction, furniture, or woodworking projects, ensuring durability and dimensional stability.

Drying Process: Kiln vs Air

Kiln-dried wood undergoes a controlled drying process in a temperature- and humidity-regulated chamber, significantly reducing moisture content to 6-8%, which enhances stability and prevents warping. Air-dried wood naturally dries over several months in open, ventilated conditions, often resulting in a higher moisture content of 12-20%, leaving the wood more prone to movement in changing environments. The kiln drying process accelerates moisture removal and ensures consistent drying, whereas air drying depends on weather conditions and ambient air circulation.

Impact on Wood Quality

Kiln-dried wood undergoes controlled, high-temperature drying, significantly reducing moisture content and enhancing durability, strength, and resistance to mold and insect damage. Air-dried wood, dried naturally over time, retains slightly higher moisture levels, which can lead to warping or cracking but preserves more of the wood's natural oils and appearance. The choice between kiln-dried and air-dried wood directly impacts woodworking precision, stability, and the final product's lifespan.

Cost Differences Explained

Kiln-dried wood typically costs more due to the energy-intensive drying process that ensures faster moisture reduction and consistent quality. Air-dried wood, relying on natural evaporation, has lower production costs but may contain higher moisture content, affecting durability and weight. The price difference reflects the trade-off between immediate usability and long-term performance, with kiln drying offering precision at a premium.

Suitability for Various Applications

Kiln-dried wood offers superior moisture control and stability, making it ideal for precision woodworking, furniture, and indoor applications where dimensional accuracy is critical. Air-dried wood retains higher moisture content, which can be advantageous for outdoor uses, rustic projects, or where natural aging and flexibility are desired. Selecting the appropriate drying method ensures optimal performance, durability, and finish quality based on the wood's end-use requirements.

Environmental Considerations

Kiln-dried wood consumes significant energy, often sourced from fossil fuels, resulting in a higher carbon footprint compared to air-dried wood, which relies on natural airflow and solar heat. Air-drying wood reduces greenhouse gas emissions and energy consumption but requires longer drying times and appropriate weather conditions to prevent fungal growth or warping. Selecting environmentally friendly drying methods depends on balancing energy use, processing time, and wood quality for sustainable forestry and construction projects.

Choosing the Right Drying Method

Kiln-dried wood undergoes a controlled drying process at high temperatures, reducing moisture content rapidly to about 6-8%, which minimizes the risk of warping and insect infestation. Air-dried wood relies on natural airflow and time, often taking several months to reach an equilibrium moisture content around 12-15%, making it more environmentally friendly but less predictable in performance. Choosing the right drying method depends on the intended use, budget, and desired wood stability, with kiln drying preferred for precision projects and air drying suitable for rustic or budget-conscious applications.

Kiln-Dried Wood vs Air-Dried Wood Infographic

materialdif.com

materialdif.com