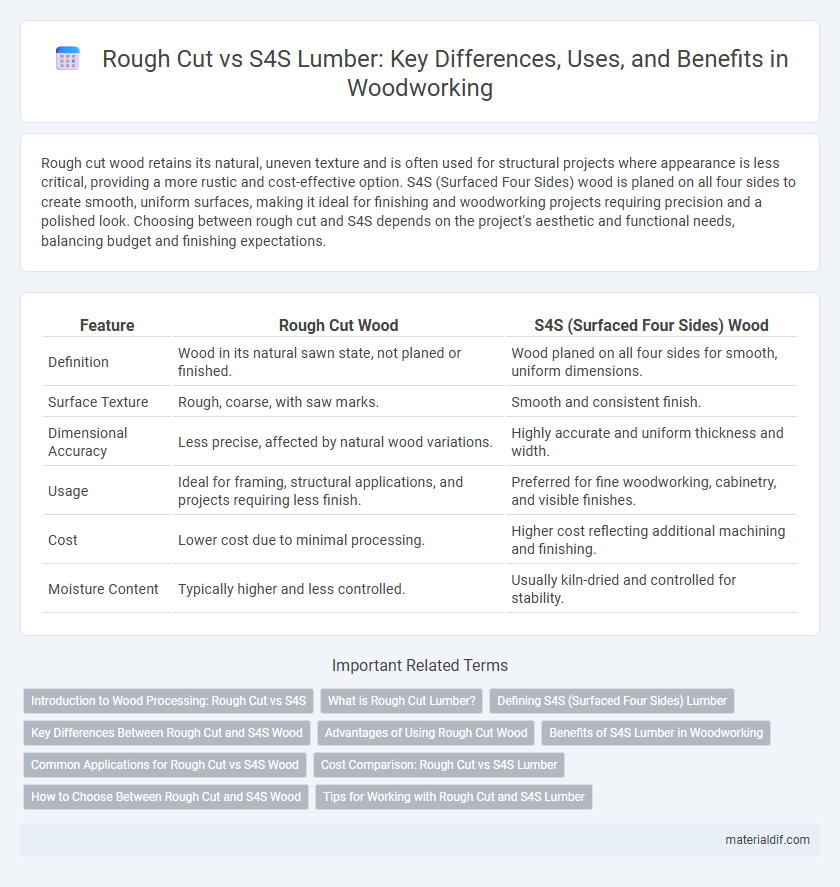

Rough cut wood retains its natural, uneven texture and is often used for structural projects where appearance is less critical, providing a more rustic and cost-effective option. S4S (Surfaced Four Sides) wood is planed on all four sides to create smooth, uniform surfaces, making it ideal for finishing and woodworking projects requiring precision and a polished look. Choosing between rough cut and S4S depends on the project's aesthetic and functional needs, balancing budget and finishing expectations.

Table of Comparison

| Feature | Rough Cut Wood | S4S (Surfaced Four Sides) Wood |

|---|---|---|

| Definition | Wood in its natural sawn state, not planed or finished. | Wood planed on all four sides for smooth, uniform dimensions. |

| Surface Texture | Rough, coarse, with saw marks. | Smooth and consistent finish. |

| Dimensional Accuracy | Less precise, affected by natural wood variations. | Highly accurate and uniform thickness and width. |

| Usage | Ideal for framing, structural applications, and projects requiring less finish. | Preferred for fine woodworking, cabinetry, and visible finishes. |

| Cost | Lower cost due to minimal processing. | Higher cost reflecting additional machining and finishing. |

| Moisture Content | Typically higher and less controlled. | Usually kiln-dried and controlled for stability. |

Introduction to Wood Processing: Rough Cut vs S4S

Rough cut lumber refers to wood that is sawn but left with a coarse, uneven surface, often used in framing or projects where appearance is not critical. S4S (Surfaced Four Sides) lumber is planed on all four sides, providing a smooth, uniform finish ideal for cabinetry, furniture, and detailed woodworking. Understanding the difference between rough cut and S4S helps in selecting the appropriate wood type based on project requirements and desired finish quality.

What is Rough Cut Lumber?

Rough cut lumber refers to wood that has been sawed to size but has not yet been planed or smoothed on any side, retaining its natural, raw texture and rough surface. It is commonly used in construction, framing, and projects where appearance is less critical, offering increased strength due to minimal processing. Unlike S4S lumber, rough cut wood requires additional finishing for furniture or detailed woodworking to achieve smoothness and uniform thickness.

Defining S4S (Surfaced Four Sides) Lumber

S4S (Surfaced Four Sides) lumber refers to wood that has been planed on all four sides to achieve uniform thickness, width, and smooth surfaces, providing precise dimensions and an improved finish compared to rough cut lumber. This type of lumber is ideal for projects requiring exact measurements and a polished appearance, reducing sanding and preparation time. The consistent sizing of S4S lumber enhances joint integrity and overall structural stability in woodworking and construction applications.

Key Differences Between Rough Cut and S4S Wood

Rough cut wood is lumber that retains a natural, coarse texture from original milling, often requiring further processing for smoothness and uniformity, while S4S (Surfaced Four Sides) wood is precision planed on all four sides for consistent dimensions and a smooth finish. Rough cut excels in rustic projects or structural uses where aesthetics are secondary, whereas S4S is preferred for cabinetry, furniture, and projects demanding a refined appearance and ease of assembly. Key differences include surface texture, dimensional accuracy, and readiness for immediate use, with S4S offering a more finished product compared to the raw, unprocessed nature of rough cut wood.

Advantages of Using Rough Cut Wood

Rough cut wood retains its natural texture, providing superior grip and a rustic aesthetic that appeals to custom woodworking projects. It is generally more affordable than S4S lumber because it requires less processing, making it a cost-effective choice for structural and framing applications. The thickness of rough cut wood allows for flexibility in planing and finishing, enabling woodworkers to achieve precise dimensions tailored to specific project needs.

Benefits of S4S Lumber in Woodworking

S4S lumber offers precise dimensions and smooth surfaces on all four sides, reducing the need for additional planing and sanding in woodworking projects. This consistency enhances joint accuracy and overall structural integrity, speeding up assembly and improving final aesthetics. Compared to rough cut lumber, S4S wood saves time and effort, making it ideal for detailed carpentry and fine furniture construction.

Common Applications for Rough Cut vs S4S Wood

Rough cut wood is commonly used in construction framing, fencing, and rustic furniture where dimensional precision is less critical, allowing for a more cost-effective material choice. S4S (Surfaced Four Sides) wood is preferred in cabinetry, trim work, and fine woodworking projects due to its smooth surfaces and consistent dimensions, which facilitate accurate joinery and finishing. The choice between rough cut and S4S wood depends on the specific application's need for precision, finish quality, and structural appearance.

Cost Comparison: Rough Cut vs S4S Lumber

Rough cut lumber generally costs 20-30% less than S4S (Surfaced Four Sides) lumber due to minimal processing and less precise milling. S4S lumber undergoes planing and sanding on all four sides, increasing labor and machinery expenses that raise the overall price. Choosing rough cut lumber can significantly reduce project costs, especially when surface smoothness and exact dimensions are not critical.

How to Choose Between Rough Cut and S4S Wood

Choosing between rough cut and S4S wood depends on the project's precision requirements and budget constraints. Rough cut wood retains its natural texture and size variability, making it ideal for rustic designs and cost-effective framing, while S4S wood offers smooth, uniform surfaces and dimensions, facilitating ease of assembly and finishing in fine woodworking and cabinetry. Evaluate the end use, desired finish quality, and need for dimensional consistency to determine the best option.

Tips for Working with Rough Cut and S4S Lumber

When working with rough cut lumber, always check for moisture content and store it properly to prevent warping or splitting during drying. Use sharp blades and take lighter passes when planing rough cut wood to minimize tear-out and achieve smooth surfaces. For S4S lumber, take advantage of the consistent thickness and smooth surfaces to speed up assembly, but still verify dimensions before cutting to ensure precision in your woodworking projects.

Rough Cut vs S4S (Surfaced Four Sides) Infographic

materialdif.com

materialdif.com