An oiled finish on wood pet furniture enhances the natural grain and provides a breathable surface that ages gracefully with regular maintenance, offering a warm, matte appearance. Lacquered finishes create a hard, protective layer that resists moisture and scratches while delivering a glossy, smooth look but may require professional refinishing if damaged. Choosing between oiled and lacquered finishes depends on desired aesthetics, durability needs, and ease of upkeep for your wood pet products.

Table of Comparison

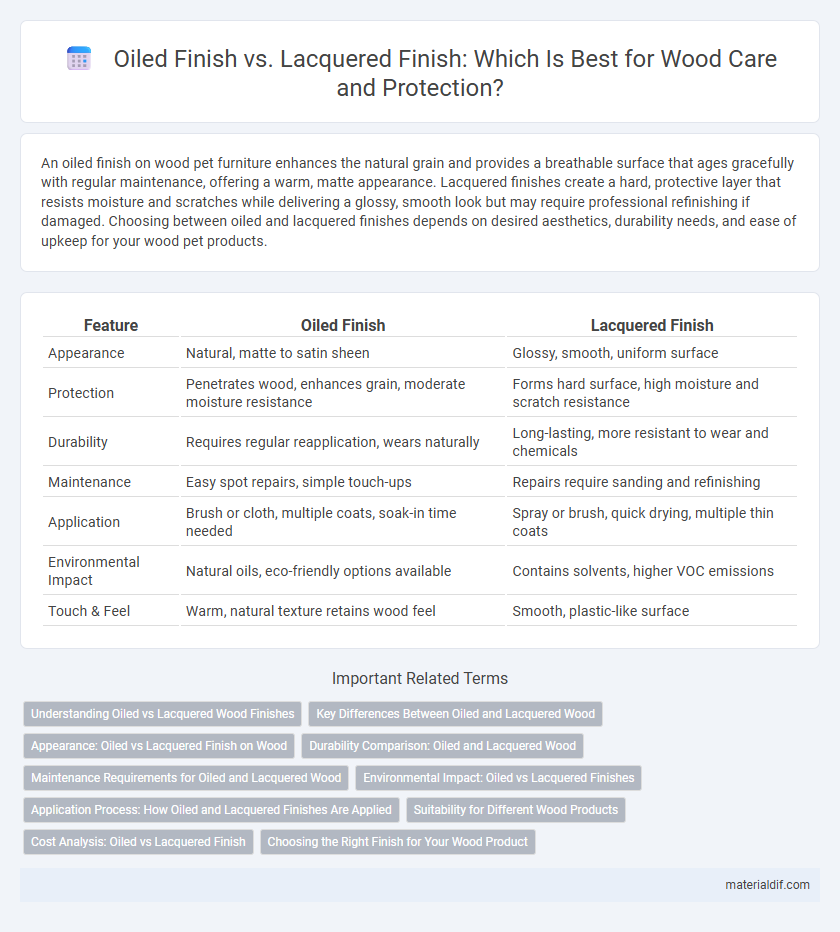

| Feature | Oiled Finish | Lacquered Finish |

|---|---|---|

| Appearance | Natural, matte to satin sheen | Glossy, smooth, uniform surface |

| Protection | Penetrates wood, enhances grain, moderate moisture resistance | Forms hard surface, high moisture and scratch resistance |

| Durability | Requires regular reapplication, wears naturally | Long-lasting, more resistant to wear and chemicals |

| Maintenance | Easy spot repairs, simple touch-ups | Repairs require sanding and refinishing |

| Application | Brush or cloth, multiple coats, soak-in time needed | Spray or brush, quick drying, multiple thin coats |

| Environmental Impact | Natural oils, eco-friendly options available | Contains solvents, higher VOC emissions |

| Touch & Feel | Warm, natural texture retains wood feel | Smooth, plastic-like surface |

Understanding Oiled vs Lacquered Wood Finishes

Oiled wood finishes penetrate the surface, enhancing natural grain and providing a breathable, matte appearance that requires periodic reapplication for maintenance. Lacquered finishes create a durable, glossy protective layer on top of the wood, offering higher resistance to scratches and moisture but can obscure the wood's natural texture. Choosing between oiled and lacquered finishes depends on the desired aesthetic, durability needs, and maintenance willingness for wooden surfaces.

Key Differences Between Oiled and Lacquered Wood

Oiled wood finish penetrates the surface, enhancing natural grain and providing a breathable, matte look while requiring periodic maintenance to retain protection. Lacquered wood finish forms a hard, protective layer on the surface, offering a glossy appearance with strong resistance to scratches and moisture but can be prone to chipping over time. The key differences between oiled and lacquered wood include durability, appearance, maintenance frequency, and the preservation of the wood's natural texture versus a sealed surface.

Appearance: Oiled vs Lacquered Finish on Wood

Oiled wood finish enhances the natural grain and texture, creating a matte, warm appearance that deepens over time with maintenance. Lacquered finish produces a glossy, smooth surface with a reflective shine, offering a more uniform and polished look that highlights color vibrancy. While oiled finishes reveal more of the wood's organic character, lacquered finishes provide a durable, sealed layer ideal for high-traffic areas.

Durability Comparison: Oiled and Lacquered Wood

Oiled wood finish penetrates deeply, enhancing natural grain while offering moderate protection against moisture and wear, making it suitable for low-traffic areas. Lacquered wood finish creates a hard, glossy surface layer that provides superior resistance to scratches, chemicals, and water, ideal for high-traffic or heavily used furniture. Over time, lacquered finishes maintain durability with minimal maintenance, whereas oiled finishes require regular reapplication to preserve protection and appearance.

Maintenance Requirements for Oiled and Lacquered Wood

Oiled wood requires regular reapplication of oil, typically every 6 to 12 months, to maintain its protective barrier and natural appearance, making it more suitable for surfaces exposed to frequent wear. Lacquered wood offers a harder, more durable finish that resists moisture and stains, requiring minimal maintenance such as occasional cleaning and polishing, but it can chip or crack over time. Proper maintenance of oiled wood involves gentle cleaning with oil-based products, while lacquered surfaces should be cleaned with mild, non-abrasive agents to preserve the integrity of the finish.

Environmental Impact: Oiled vs Lacquered Finishes

Oiled finishes use natural oils like tung or linseed, which are biodegradable and emit fewer volatile organic compounds (VOCs), making them a more environmentally friendly option compared to lacquered finishes. Lacquered finishes often contain synthetic chemicals and solvents that release higher levels of VOCs, contributing to air pollution and potential health risks. Sustainable wood treatments prioritize low environmental impact, with oiled finishes offering better biodegradability and reduced toxicity.

Application Process: How Oiled and Lacquered Finishes Are Applied

Oiled finishes are applied by rubbing or brushing the oil into the wood grain, allowing it to penetrate and enhance the texture, followed by wiping off excess oil and curing naturally. Lacquered finishes require spraying or brushing multiple thin layers of lacquer, with each coat typically needing to dry and be lightly sanded before the next application to achieve a smooth, durable surface. This application process makes oiled finishes simpler and more forgiving for DIY projects, while lacquered finishes demand more precision and controlled conditions for professional results.

Suitability for Different Wood Products

Oiled finishes penetrate deeply into wood, enhancing natural grain patterns and providing a matte, warm appearance ideal for rustic furniture, wooden cutting boards, and outdoor decking. Lacquered finishes create a hard, glossy surface that offers superior protection against scratches and moisture, making them suitable for indoor furniture, cabinetry, and decorative woodwork. Choosing between oiled and lacquered finishes depends largely on the wood product's intended use, exposure to wear, and desired aesthetic.

Cost Analysis: Oiled vs Lacquered Finish

Oiled wood finishes generally cost less upfront than lacquered finishes, with prices typically ranging from $15 to $30 per gallon for oil compared to $30 to $60 per gallon for lacquer. Maintenance expenses for oiled finishes can be higher over time due to the need for periodic reapplication every 1-3 years, while lacquered surfaces require less frequent upkeep but more intensive initial application costs. Considering both initial and long-term expenses, oiled finishes may offer cost savings for small projects, whereas lacquered finishes provide durability with potentially lower maintenance investment for larger or commercial wood applications.

Choosing the Right Finish for Your Wood Product

Selecting the right finish for your wood product impacts durability, appearance, and maintenance. Oiled finishes penetrate the wood, enhancing natural grain with a matte or satin effect while allowing easy repairs and reapplication, ideal for furniture and floors exposed to wear. Lacquered finishes create a hard, protective coating with high gloss options, providing greater resistance to moisture and scratches, making them suitable for decorative items and high-traffic surfaces.

Oiled Finish vs Lacquered Finish Infographic

materialdif.com

materialdif.com