Butt joints are simple and quick to create, ideal for basic woodworking projects but lack strength and durability compared to dovetail joints. Dovetail joints interlock with a series of trapezoidal pins and tails, providing exceptional tensile strength that is perfect for sturdy, long-lasting wood pet furniture. Choosing dovetail joints ensures enhanced stability and resistance to pulling apart, making them the preferred option for high-quality wood pet enclosures and accessories.

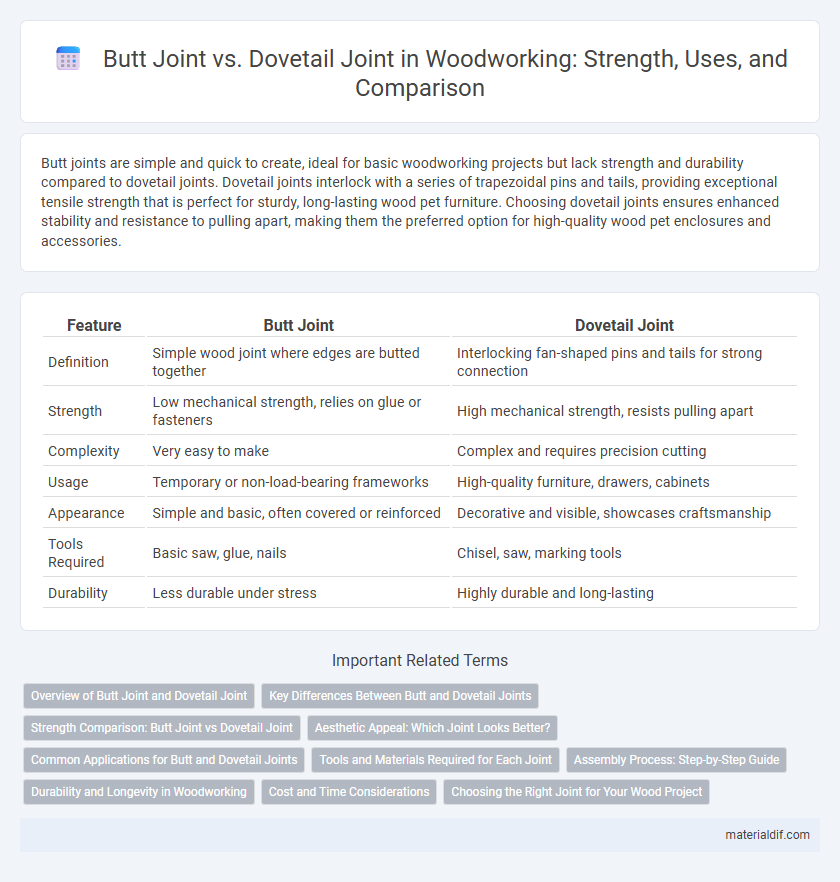

Table of Comparison

| Feature | Butt Joint | Dovetail Joint |

|---|---|---|

| Definition | Simple wood joint where edges are butted together | Interlocking fan-shaped pins and tails for strong connection |

| Strength | Low mechanical strength, relies on glue or fasteners | High mechanical strength, resists pulling apart |

| Complexity | Very easy to make | Complex and requires precision cutting |

| Usage | Temporary or non-load-bearing frameworks | High-quality furniture, drawers, cabinets |

| Appearance | Simple and basic, often covered or reinforced | Decorative and visible, showcases craftsmanship |

| Tools Required | Basic saw, glue, nails | Chisel, saw, marking tools |

| Durability | Less durable under stress | Highly durable and long-lasting |

Overview of Butt Joint and Dovetail Joint

Butt joints are one of the simplest wood joinery methods where two pieces of wood are joined at their ends or edges, commonly secured with nails, screws, or glue, offering quick assembly but limited strength. Dovetail joints feature interlocking, fan-shaped pins and tails that provide superior tensile strength and resistance to being pulled apart, making them ideal for drawer construction and fine woodworking. While butt joints prioritize ease and speed, dovetail joints are favored for durability and aesthetic appeal in woodworking projects.

Key Differences Between Butt and Dovetail Joints

Butt joints involve simply joining two pieces of wood end-to-end or edge-to-edge without additional interlocking, making them easier to create but less strong and durable. In contrast, dovetail joints feature interlocking, trapezoidal pins and tails that provide superior tensile strength and resistance to pulling apart, commonly used in drawer construction for enhanced longevity. The choice between butt and dovetail joints impacts structural integrity, aesthetic appeal, and the complexity of woodworking projects.

Strength Comparison: Butt Joint vs Dovetail Joint

Dovetail joints provide superior strength compared to butt joints due to their interlocking design, which resists pulling apart and distributes stress evenly across the joint. Butt joints rely solely on glue or fasteners, making them weaker and more prone to failure under tension or shear forces. In woodworking, dovetail joints are preferred for load-bearing connections, especially in drawer construction and cabinetry, due to their enhanced durability and mechanical strength.

Aesthetic Appeal: Which Joint Looks Better?

Dovetail joints exhibit a superior aesthetic appeal due to their intricate interlocking pattern, often highlighted in fine woodworking and cabinetry for visual elegance and craftsmanship. Butt joints, while simpler and less visually engaging, provide a clean and minimalistic look but lack the decorative complexity of dovetails. The choice between the two hinges on whether the project prioritizes decorative detail or straightforward simplicity in appearance.

Common Applications for Butt and Dovetail Joints

Butt joints are commonly used in simple frame constructions, furniture making, and basic cabinetry due to their ease of assembly and suitability for pieces requiring quick joinery without heavy load bearing. Dovetail joints predominantly appear in high-quality drawer construction, fine cabinetry, and woodworking projects demanding superior strength and aesthetic appeal, offering enhanced resistance to pulling forces. Each joint's application is determined by the balance between structural integrity and craftsmanship requirements specific to woodworking or furniture design tasks.

Tools and Materials Required for Each Joint

The butt joint requires basic tools such as a saw, hammer, nails or screws, and wood glue, making it suitable for simple woodworking projects with minimal material expense. The dovetail joint demands more specialized tools, including a dovetail saw, chisels, marking gauges, and clamps, alongside hardwood that can withstand precise cutting and interlocking for enhanced strength. Materials for dovetail joints typically involve hardwoods like oak or maple, while butt joints can be made with various soft or hardwoods due to their less complex structure.

Assembly Process: Step-by-Step Guide

The assembly process for a butt joint involves aligning two wood pieces at a right angle and securing them with nails, screws, or glue, emphasizing simplicity and speed. In contrast, the dovetail joint requires precise cutting of interlocking pins and tails, often using a dovetail saw and chisels, ensuring a tight, durable fit without additional fasteners. Mastery of dovetail joint assembly enhances structural integrity and aesthetic appeal, making it ideal for high-quality woodworking projects.

Durability and Longevity in Woodworking

Butt joints, while simple and quick to assemble, lack the interlocking strength of dovetail joints, making them less durable under stress and prone to separation over time. Dovetail joints offer superior longevity due to their mechanical interlock, which resists pulling forces and distributes loads evenly, enhancing the structural integrity of wooden furniture. Woodworkers often choose dovetail joints for high-quality cabinetry and drawers to ensure long-lasting performance and durability.

Cost and Time Considerations

Butt joints are more cost-effective and quicker to produce due to their simple design, requiring minimal tools and skill, making them ideal for budget-conscious or large-scale projects. Dovetail joints, while more expensive and time-consuming because of the precision and craftsmanship involved, offer superior strength and durability, justifying their higher investment in fine woodworking and cabinetry. Selecting between these joints depends on balancing project budget, time constraints, and the desired structural integrity for the wood assembly.

Choosing the Right Joint for Your Wood Project

Butt joints are simple and quick to create, making them ideal for basic woodworking projects where strength is not a primary concern, such as cabinet backs or picture frames. Dovetail joints provide exceptional tensile strength and interlocking precision, making them perfect for drawers and furniture requiring durability and aesthetic appeal. Selecting the right joint depends on factors like load resistance, craftsmanship level, and the intended use of the wooden item.

Butt joint vs Dovetail joint Infographic

materialdif.com

materialdif.com