Particle board is made from wood chips and resin, offering an affordable and lightweight option commonly used in furniture and cabinetry. HDF (High Density Fiberboard) is denser, stronger, and smoother due to finely ground wood fibers, making it ideal for applications requiring durability and a high-quality finish. Choosing between particle board and HDF depends on the balance between cost, strength, and surface quality needed for a specific woodworking project.

Table of Comparison

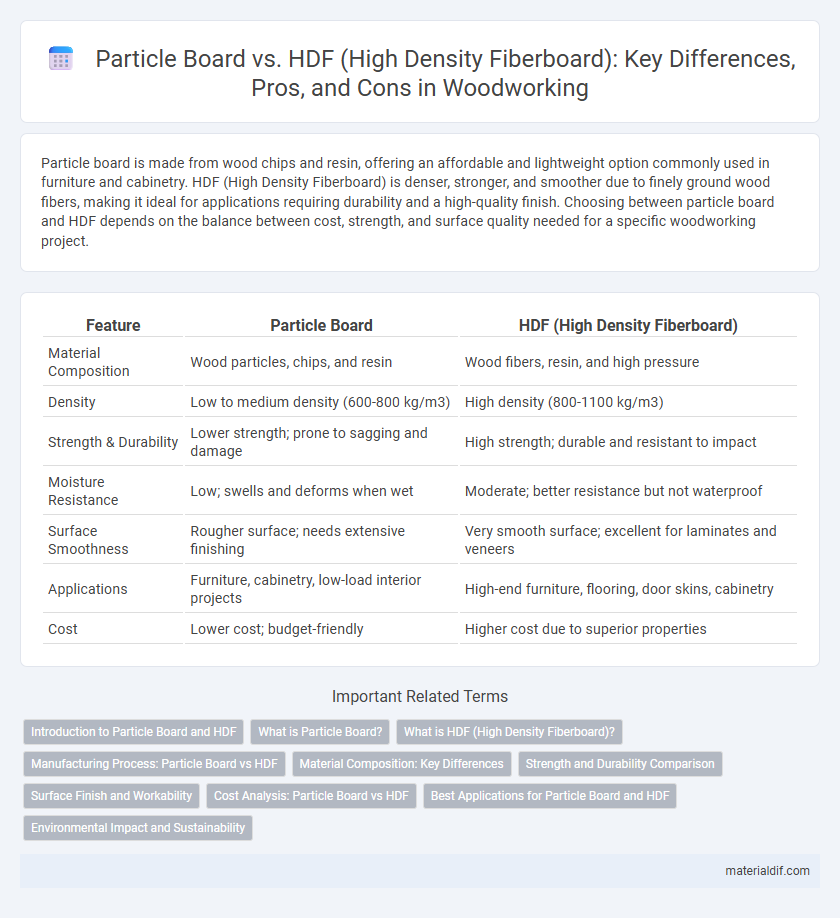

| Feature | Particle Board | HDF (High Density Fiberboard) |

|---|---|---|

| Material Composition | Wood particles, chips, and resin | Wood fibers, resin, and high pressure |

| Density | Low to medium density (600-800 kg/m3) | High density (800-1100 kg/m3) |

| Strength & Durability | Lower strength; prone to sagging and damage | High strength; durable and resistant to impact |

| Moisture Resistance | Low; swells and deforms when wet | Moderate; better resistance but not waterproof |

| Surface Smoothness | Rougher surface; needs extensive finishing | Very smooth surface; excellent for laminates and veneers |

| Applications | Furniture, cabinetry, low-load interior projects | High-end furniture, flooring, door skins, cabinetry |

| Cost | Lower cost; budget-friendly | Higher cost due to superior properties |

Introduction to Particle Board and HDF

Particle Board is an engineered wood product made from wood chips, sawmill shavings, or sawdust bonded together with resin under heat and pressure, offering affordability and versatility for furniture and cabinetry. High Density Fiberboard (HDF) is a denser, more durable version of medium-density fiberboard (MDF), manufactured by compressing wood fibers with resin at higher pressure, providing a smoother surface and enhanced strength for flooring and paneling. Both materials are widely used in woodworking but vary significantly in density, strength, and applications.

What is Particle Board?

Particle board is an engineered wood product made from wood chips, sawdust, and resin compressed under high pressure and heat to form dense, flat panels. It is commonly used in furniture manufacturing and interior construction due to its affordability and ease of machining. Although particle board is less durable and moisture-resistant than HDF (High Density Fiberboard), it offers a cost-effective solution for budget-conscious applications.

What is HDF (High Density Fiberboard)?

HDF (High Density Fiberboard) is an engineered wood product made by compressing wood fibers with resin under high pressure and heat, resulting in a dense, durable panel. It offers superior strength, smooth surface finish, and resistance to impact compared to Particle Board, making it ideal for furniture, flooring, and cabinetry applications. HDF's fine texture and uniform density provide excellent paintability and machinability, enhancing its versatility in woodworking projects.

Manufacturing Process: Particle Board vs HDF

Particle board is manufactured by compressing wood chips, sawmill shavings, and sawdust mixed with synthetic resin adhesives under moderate heat and pressure. HDF (High Density Fiberboard) is produced by refining wood fibers into a fine consistency, then compressing them at higher pressures and temperatures compared to particle board, resulting in a denser and stronger panel. The distinct manufacturing processes influence the density, strength, and surface smoothness of the final products, with HDF offering superior durability due to its fiber refinement and higher compression.

Material Composition: Key Differences

Particle board consists of wood chips, sawdust, and resin compressed under heat and pressure, resulting in a lightweight, economical panel with moderate strength. HDF (High Density Fiberboard) is made from refined wood fibers, combined with resin and pressed at higher density and pressure, offering superior hardness, durability, and resistance to impact. The fine fiber composition of HDF provides a smoother surface finish compared to the coarser particle composition of particle board, making it more suitable for applications requiring precision and strength.

Strength and Durability Comparison

Particle board, made from wood chips and resin, offers moderate strength but is more susceptible to moisture damage and wear over time compared to High Density Fiberboard (HDF). HDF's denser composition, pressed at higher temperatures and pressures, results in superior durability, resistance to impact, and structural integrity, making it ideal for applications requiring long-lasting performance. Strength metrics show HDF typically outperforms particle board in bending strength and screw holding capacity, increasing its suitability for furniture and flooring under heavy usage.

Surface Finish and Workability

Particle board offers a rougher surface finish prone to chipping, requiring extensive sanding and sealing before painting or laminating. HDF (High Density Fiberboard) provides a smooth, dense surface ideal for high-quality finishes and detailed painting without significant prep work. Workability differs as particle board can be more fragile when cutting and routing, while HDF allows precise machining with minimal surface tear-out.

Cost Analysis: Particle Board vs HDF

Particle board offers a lower cost option compared to High Density Fiberboard (HDF) due to its less dense composition and simpler manufacturing process. HDF, while more expensive, provides superior strength and durability, making it a cost-effective choice for long-term applications despite higher initial investment. Budget-conscious projects prioritize particle board for affordability, whereas HDF suits demanding environments where enhanced performance justifies the cost.

Best Applications for Particle Board and HDF

Particle board is best suited for lightweight furniture, shelving, and cabinetry where cost-effectiveness and ease of machining are priorities. HDF (High Density Fiberboard) excels in applications requiring superior durability and smooth surface finishes, such as laminate flooring, doors, and high-quality furniture components. Both materials provide versatile solutions, but particle board is preferred for budget-friendly interior projects while HDF is chosen for high-performance and aesthetic demands.

Environmental Impact and Sustainability

Particle board is typically made from wood chips, sawdust, and resin, often utilizing recycled wood materials which reduces waste and decreases reliance on virgin timber, contributing positively to sustainability efforts. HDF (High Density Fiberboard) requires more energy and resin binding agents in its manufacturing process, which can lead to higher environmental impacts, including greater carbon emissions and potential formaldehyde release. Both materials offer eco-friendly options when sourced responsibly, but particle board generally has a lower overall environmental footprint due to its use of recycled content and less intensive production.

Particle Board vs HDF (High Density Fiberboard) Infographic

materialdif.com

materialdif.com