Particleboard is made from wood chips and resin, resulting in a cost-effective material with lower density and strength compared to MDF. MDF, or medium-density fiberboard, consists of fine wood fibers combined under heat and pressure, offering a smoother surface and increased durability ideal for detailed woodworking. Both materials serve as versatile alternatives to solid wood, but MDF excels in finish quality and resistance to warping.

Table of Comparison

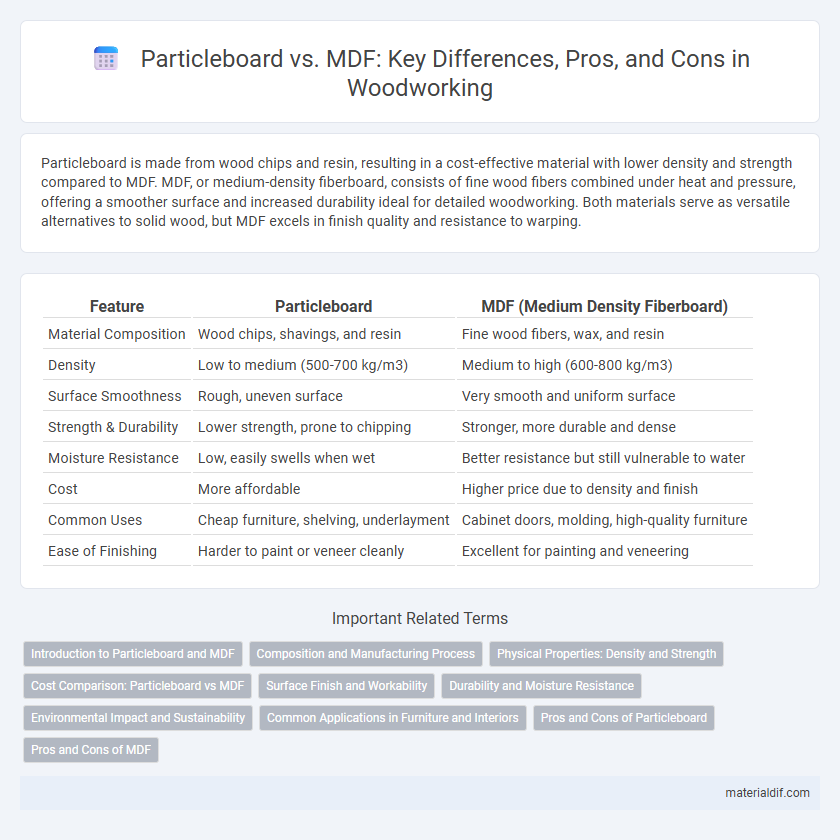

| Feature | Particleboard | MDF (Medium Density Fiberboard) |

|---|---|---|

| Material Composition | Wood chips, shavings, and resin | Fine wood fibers, wax, and resin |

| Density | Low to medium (500-700 kg/m3) | Medium to high (600-800 kg/m3) |

| Surface Smoothness | Rough, uneven surface | Very smooth and uniform surface |

| Strength & Durability | Lower strength, prone to chipping | Stronger, more durable and dense |

| Moisture Resistance | Low, easily swells when wet | Better resistance but still vulnerable to water |

| Cost | More affordable | Higher price due to density and finish |

| Common Uses | Cheap furniture, shelving, underlayment | Cabinet doors, molding, high-quality furniture |

| Ease of Finishing | Harder to paint or veneer cleanly | Excellent for painting and veneering |

Introduction to Particleboard and MDF

Particleboard is an engineered wood product made from wood chips, sawmill shavings, and resin, offering a cost-effective and lightweight solution for furniture and cabinetry. Medium Density Fiberboard (MDF) is produced by breaking down hardwood or softwood residuals into fine fibers, combining them with wax and resin under heat and pressure to create a dense, smooth surface ideal for painting and intricate designs. Both materials serve as versatile alternatives to solid wood, with particleboard emphasizing affordability and MDF focusing on strength and finish quality.

Composition and Manufacturing Process

Particleboard is composed of wood chips, sawdust, and resin bonded under high pressure and heat, creating a dense and economical engineered wood product. MDF (Medium Density Fiberboard) consists of fine wood fibers combined with wax and resin, then compressed at higher pressures than particleboard, resulting in a smoother and more uniform surface. The manufacturing process of MDF involves breaking down wood into fibers, which allows for greater machining precision compared to the coarser particleboard made from larger wood particles.

Physical Properties: Density and Strength

Particleboard typically has a density ranging from 600 to 800 kg/m3, making it lighter but less durable compared to MDF, which has a denser range of 600 to 1,000 kg/m3. MDF's fine fibers and higher density contribute to superior strength and smoothness, enhancing its suitability for detailed machining and furniture applications. The varying density directly impacts load-bearing capacity, with MDF generally outperforming particleboard in structural integrity and resistance to warping.

Cost Comparison: Particleboard vs MDF

Particleboard is generally more cost-effective than MDF due to its composition of wood chips and resin, making it cheaper to produce and purchase. MDF, made from finely ground wood fibers and resin, tends to have a higher manufacturing cost, resulting in a relatively higher market price. For budget-conscious projects, particleboard offers significant savings, while MDF provides better durability and finish at a premium cost.

Surface Finish and Workability

Particleboard features a rougher surface finish compared to MDF, making it less suitable for smooth paints or veneers without additional sanding or sealing. MDF offers a finer, more uniform surface texture that accepts paint and laminates easily, resulting in a high-quality finish. In terms of workability, MDF cuts and shapes cleanly with minimal splintering, whereas particleboard is prone to chipping and requires more careful handling during machining.

Durability and Moisture Resistance

Particleboard offers moderate durability and is more prone to swelling and warping when exposed to moisture, making it less suitable for humid environments. MDF (Medium Density Fiberboard) demonstrates higher density and strength, providing superior durability and better resistance to moisture, especially when treated or sealed properly. Both materials benefit from protective coatings, but MDF generally outperforms particleboard in longevity and moisture resilience in wood applications.

Environmental Impact and Sustainability

Particleboard is often considered more environmentally friendly than MDF due to its use of wood chips, sawdust, and other wood waste materials, reducing landfill waste and promoting resource efficiency. MDF typically requires more energy-intensive manufacturing processes and resins containing formaldehyde, which can emit volatile organic compounds (VOCs) affecting indoor air quality. Both materials benefit from certifications like FSC and CARB compliance, but particleboard's lower density and incorporation of recycled content generally result in a smaller carbon footprint and better sustainability profile.

Common Applications in Furniture and Interiors

Particleboard is widely used in budget-friendly furniture such as flat-pack cabinets, shelving, and underlayment due to its cost-effectiveness and adequate strength. MDF serves premium furniture and interior applications like decorative molding, intricate paneling, and painted surfaces because of its smooth finish and superior machinability. Both materials are integral in interior design, with particleboard often acting as a core substrate and MDF providing detailed, high-quality aesthetics.

Pros and Cons of Particleboard

Particleboard offers cost-effectiveness and good dimensional stability, making it suitable for budget-friendly furniture and interior applications. Its main disadvantages are lower strength and durability compared to MDF, with susceptibility to moisture damage causing swelling and structural weakening. Particleboard's lightweight nature facilitates easier handling but limits its use in load-bearing or high-wear situations.

Pros and Cons of MDF

Medium Density Fiberboard (MDF) offers a smooth surface ideal for painting and intricate woodworking due to its uniform density and lack of grain. It is more affordable and easier to machine than solid wood but tends to absorb moisture, leading to swelling and reduced durability in damp environments. MDF is heavier and less resistant to impact and screw holding compared to Particleboard, making it less suitable for structural applications.

Particleboard vs MDF Infographic

materialdif.com

materialdif.com