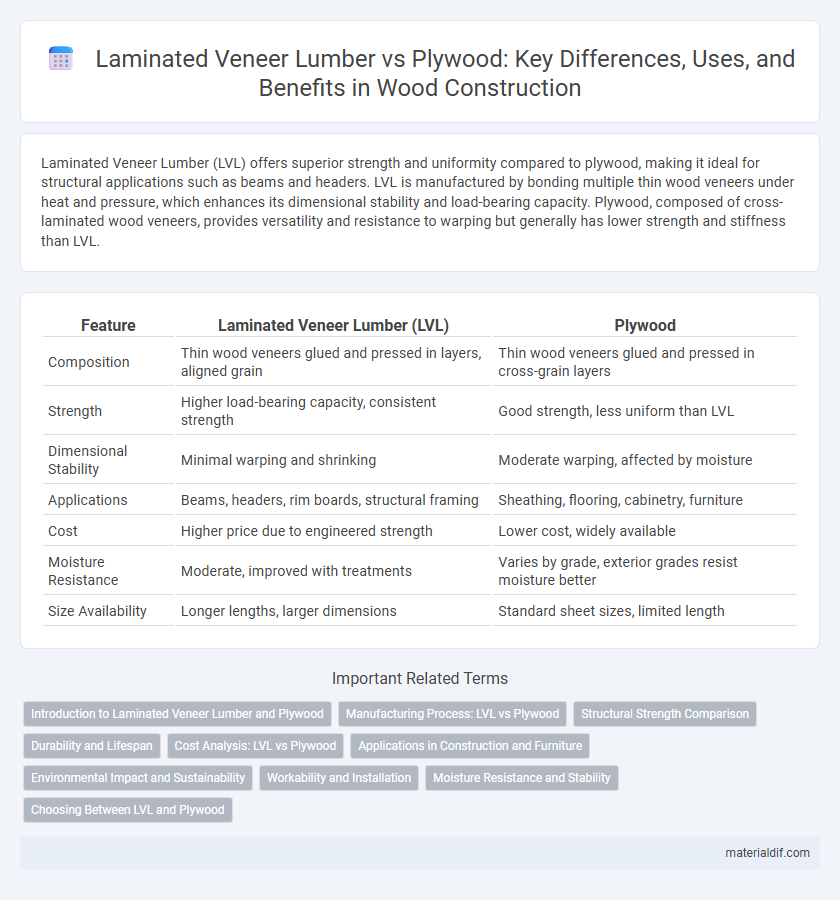

Laminated Veneer Lumber (LVL) offers superior strength and uniformity compared to plywood, making it ideal for structural applications such as beams and headers. LVL is manufactured by bonding multiple thin wood veneers under heat and pressure, which enhances its dimensional stability and load-bearing capacity. Plywood, composed of cross-laminated wood veneers, provides versatility and resistance to warping but generally has lower strength and stiffness than LVL.

Table of Comparison

| Feature | Laminated Veneer Lumber (LVL) | Plywood |

|---|---|---|

| Composition | Thin wood veneers glued and pressed in layers, aligned grain | Thin wood veneers glued and pressed in cross-grain layers |

| Strength | Higher load-bearing capacity, consistent strength | Good strength, less uniform than LVL |

| Dimensional Stability | Minimal warping and shrinking | Moderate warping, affected by moisture |

| Applications | Beams, headers, rim boards, structural framing | Sheathing, flooring, cabinetry, furniture |

| Cost | Higher price due to engineered strength | Lower cost, widely available |

| Moisture Resistance | Moderate, improved with treatments | Varies by grade, exterior grades resist moisture better |

| Size Availability | Longer lengths, larger dimensions | Standard sheet sizes, limited length |

Introduction to Laminated Veneer Lumber and Plywood

Laminated Veneer Lumber (LVL) is an engineered wood product made by bonding thin wood veneers together under heat and pressure, offering superior strength and stiffness compared to traditional lumber. Plywood consists of multiple layers of thin wood veneers glued with grain patterns alternating at 90 degrees, enhancing dimensional stability and resistance to warping. Both LVL and plywood are widely used in construction for beams, headers, and panels, with LVL preferred for load-bearing applications due to its consistent strength and plywood favored for sheathing and subflooring because of its flexibility and cost-effectiveness.

Manufacturing Process: LVL vs Plywood

Laminated Veneer Lumber (LVL) is manufactured by layering thin wood veneers bonded together with adhesives under heat and pressure, aligning grains parallel to enhance strength and uniformity. Plywood is made by gluing together multiple thin layers of wood veneers, with adjacent layers' grain patterns oriented perpendicular to each other, providing dimensional stability and resistance to warping. The LVL process produces a stronger, more consistent engineered wood product suitable for structural applications, whereas plywood's cross-grain construction offers superior resistance to splitting and bending.

Structural Strength Comparison

Laminated Veneer Lumber (LVL) offers superior structural strength compared to plywood due to its engineered composition of multiple thin wood veneers glued under heat and pressure, providing higher load-bearing capacity and dimensional stability. LVL's consistent grain orientation and adhesive bonding result in enhanced resistance to bending, warping, and shear forces compared to plywood's layered grain structure. This makes LVL ideal for beams, headers, and joists in construction projects requiring reliable strength and durability.

Durability and Lifespan

Laminated Veneer Lumber (LVL) offers superior durability and a longer lifespan compared to plywood due to its engineered layers of thin wood veneers bonded with strong adhesives. LVL resists warping, splitting, and delamination better under stress, making it ideal for structural applications requiring high strength and stability. Plywood, while versatile and cost-effective, generally has a shorter lifespan when exposed to moisture and heavy loads, resulting in faster degradation over time.

Cost Analysis: LVL vs Plywood

Laminated Veneer Lumber (LVL) typically presents a higher upfront cost compared to plywood due to its engineered composition and superior strength properties. LVL offers enhanced load-bearing capacity and dimensional stability, which can translate to long-term savings in structural applications despite the initial investment. Plywood, while more affordable initially, may incur higher maintenance and replacement costs over time because of its susceptibility to warping and moisture damage.

Applications in Construction and Furniture

Laminated Veneer Lumber (LVL) offers superior strength and stability, making it ideal for structural applications like beams, headers, and joists in construction where load-bearing capacity is critical. Plywood, with its versatile layering and cost-effective manufacturing, excels in furniture production and interior paneling due to its smooth surface and aesthetic appeal. Both materials serve complementary roles in construction and furniture, with LVL favored for high-stress structural components and plywood preferred for decorative and non-load-bearing applications.

Environmental Impact and Sustainability

Laminated Veneer Lumber (LVL) offers enhanced sustainability by utilizing fast-growing hardwood species and optimizing wood fiber use, resulting in lower environmental impact compared to traditional plywood production that often relies on plywood sourced from older, slower-growing trees. LVL manufacturing processes generate less waste and typically involve fewer adhesives with lower volatile organic compound (VOC) emissions, contributing to improved indoor air quality and reduced carbon footprint. Both materials contribute to responsible forestry, but LVL's structural efficiency and resource utilization make it a more environmentally favorable choice.

Workability and Installation

Laminated Veneer Lumber (LVL) offers superior workability due to its uniform strength and consistent thickness, allowing for precise cuts and easy fastening without delamination. Plywood, while versatile, often presents challenges during installation because of its tendency to splinter and uneven layers, which can complicate nailing and screw placement. The engineered structure of LVL provides enhanced stability and ease in framing applications, making it a preferred choice for streamlined construction processes.

Moisture Resistance and Stability

Laminated Veneer Lumber (LVL) offers superior moisture resistance compared to plywood due to its engineered construction, which reduces the likelihood of warping and delamination under humid conditions. The cross-layered veneer arrangement in LVL enhances dimensional stability, maintaining structural integrity even in fluctuating moisture environments. Plywood, while cost-effective, tends to absorb water more readily, leading to swelling and reduced durability over time.

Choosing Between LVL and Plywood

Choosing between Laminated Veneer Lumber (LVL) and plywood depends on structural requirements and application specifics. LVL offers superior strength, dimensional stability, and uniformity, making it ideal for load-bearing beams and headers in construction. Plywood provides greater flexibility, resistance to warping, and cost-effectiveness, often preferred for sheathing, flooring, and non-structural panels.

Laminated Veneer Lumber vs Plywood Infographic

materialdif.com

materialdif.com