CNC routing offers unparalleled precision and efficiency in wood crafting compared to manual carpentry, allowing for intricate designs and consistent repeatability. While manual carpentry provides tactile control and traditional craftsmanship valued for unique, customized pieces, CNC routing significantly reduces production time and material waste. Choosing between CNC routing and manual carpentry depends on project complexity, desired finish, and production scale.

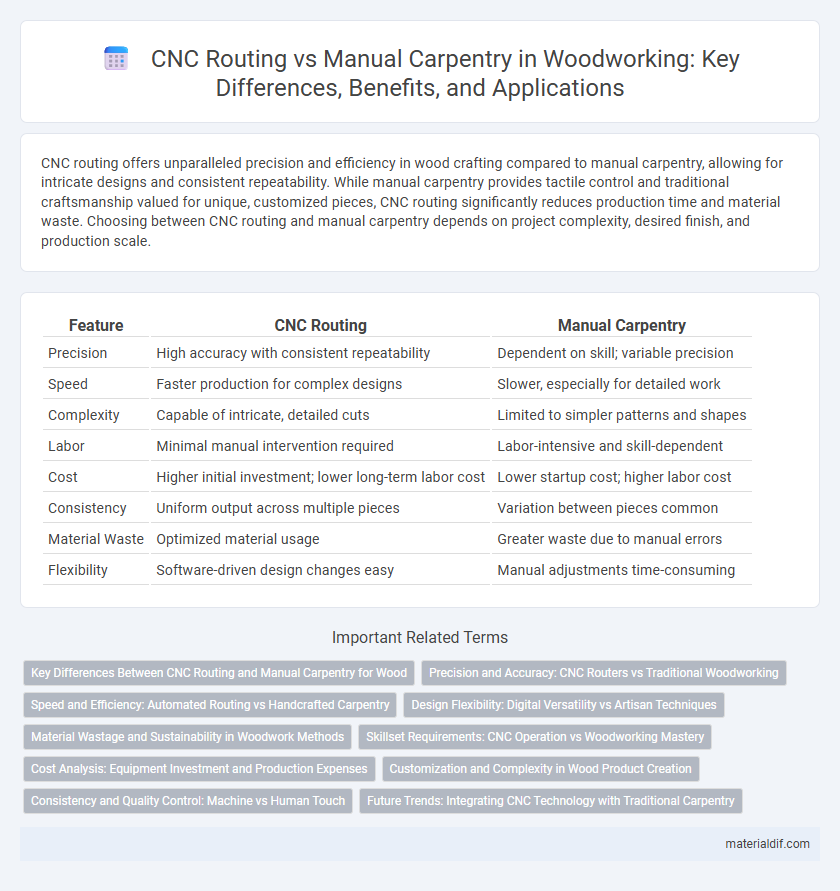

Table of Comparison

| Feature | CNC Routing | Manual Carpentry |

|---|---|---|

| Precision | High accuracy with consistent repeatability | Dependent on skill; variable precision |

| Speed | Faster production for complex designs | Slower, especially for detailed work |

| Complexity | Capable of intricate, detailed cuts | Limited to simpler patterns and shapes |

| Labor | Minimal manual intervention required | Labor-intensive and skill-dependent |

| Cost | Higher initial investment; lower long-term labor cost | Lower startup cost; higher labor cost |

| Consistency | Uniform output across multiple pieces | Variation between pieces common |

| Material Waste | Optimized material usage | Greater waste due to manual errors |

| Flexibility | Software-driven design changes easy | Manual adjustments time-consuming |

Key Differences Between CNC Routing and Manual Carpentry for Wood

CNC routing offers precise, automated cutting and shaping of wood with high repeatability, reducing human error compared to manual carpentry, which relies heavily on skilled craftsmanship and hand tools. CNC machines can execute complex designs quickly and consistently, while manual carpentry excels in customization and intricate detailing that requires human judgment. The integration of CAD software in CNC routing enables efficient production workflows, contrasting with the labor-intensive, time-consuming processes typical of manual woodworking.

Precision and Accuracy: CNC Routers vs Traditional Woodworking

CNC routing delivers unmatched precision and accuracy in woodworking by utilizing computer-controlled tools that follow exact digital designs, ensuring consistent cuts and intricate detailing. Traditional manual carpentry relies heavily on the skill and experience of the craftsman, which can lead to variability and minor imperfections in measurements and cuts. The repeatability and precision of CNC routers make them ideal for complex projects demanding high accuracy, whereas manual methods are better suited for unique, handcrafted pieces.

Speed and Efficiency: Automated Routing vs Handcrafted Carpentry

CNC routing significantly outpaces manual carpentry in speed and efficiency by automating intricate cuts with precision, reducing production time by up to 70%. Automated routing systems minimize human error and material waste, increasing overall productivity in woodworking projects. While handcrafted carpentry offers unique artistry, CNC technology maximizes output for large-scale manufacturing without compromising detail accuracy.

Design Flexibility: Digital Versatility vs Artisan Techniques

CNC routing offers unparalleled design flexibility through precise digital control and the ability to replicate complex patterns consistently, enabling intricate and customizable woodwork unattainable by manual methods. Manual carpentry relies on artisan techniques that bring unique character and subtle variations to each piece, but its design scope is limited by human skill and time constraints. The digital versatility of CNC routing expands creative possibilities in woodworking, while manual craftsmanship preserves traditional aesthetics and individual artistry.

Material Wastage and Sustainability in Woodwork Methods

CNC routing minimizes material wastage through precise digital cutting, optimizing wood usage and reducing offcuts compared to manual carpentry, which often results in higher scrap rates due to human error. This precision enables sustainable woodwork by maximizing timber yield from each board, supporting eco-friendly practices in the woodworking industry. Implementing CNC technology aligns with sustainable forestry by lowering demand for raw wood and promoting efficient resource management.

Skillset Requirements: CNC Operation vs Woodworking Mastery

CNC routing demands proficiency in computer-aided design (CAD) software and precise machine operation, emphasizing technical and digital skills. Manual carpentry relies heavily on traditional woodworking mastery, including hand tool dexterity, material knowledge, and creative problem-solving. Each approach requires distinct skill sets that impact efficiency, accuracy, and the ability to handle complex design challenges in wood fabrication.

Cost Analysis: Equipment Investment and Production Expenses

CNC routing requires a significant initial equipment investment, often ranging from $15,000 to $100,000, compared to manual carpentry tools, which typically cost under $5,000. Production expenses for CNC routing are lower due to automation, reducing labor costs and material waste, while manual carpentry involves higher labor intensity and slower output, increasing ongoing expenses. Over time, CNC routing offers better cost efficiency for large-scale production despite the high upfront costs, whereas manual carpentry remains more viable for small projects and custom work due to lower initial expenses.

Customization and Complexity in Wood Product Creation

CNC routing offers unparalleled precision and repeatability in wood product creation, enabling complex designs and intricate patterns that are difficult to achieve with manual carpentry. Customization is streamlined through computer-aided design (CAD) software, allowing for exact replication of bespoke features and rapid adjustments without compromising quality. Manual carpentry relies heavily on skilled craftsmanship, which allows for unique artistic touches but can limit complexity and consistency in customized wood products.

Consistency and Quality Control: Machine vs Human Touch

CNC routing ensures high consistency and precise quality control by following programmed specifications without deviation, reducing the risk of human error common in manual carpentry. In contrast, manual carpentry offers unique craftsmanship but can result in variability between pieces due to human factors such as fatigue and skill level. Automated CNC systems maintain uniform finishes and dimensions, making them ideal for mass production and projects requiring exact replication.

Future Trends: Integrating CNC Technology with Traditional Carpentry

Integrating CNC technology with traditional carpentry is transforming woodworking by enhancing precision and efficiency while preserving artisanal craftsmanship. Advanced CNC routers equipped with AI and automation enable complex designs and mass customization, meeting rising consumer demand for personalized wood products. Combining digital accuracy with manual skill is set to drive innovation in furniture making, cabinetry, and architectural woodwork, establishing a new standard in the industry.

CNC Routing vs Manual Carpentry Infographic

materialdif.com

materialdif.com