Engineered wood combines layers of wood veneers or fibers bonded with adhesives, offering enhanced stability and resistance to warping compared to solid wood, which is crafted from a single piece of timber. While solid wood provides natural beauty, durability, and a unique grain pattern, engineered wood excels in affordability, dimension consistency, and environmental sustainability. Choosing between engineered and solid wood depends on project requirements, desired aesthetics, and budget constraints.

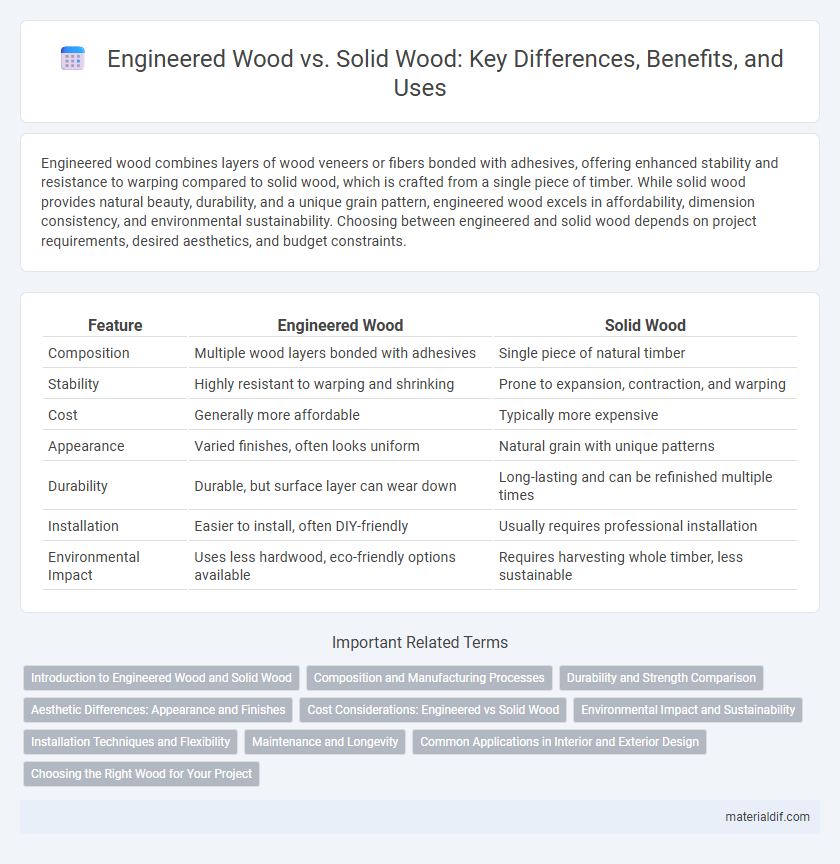

Table of Comparison

| Feature | Engineered Wood | Solid Wood |

|---|---|---|

| Composition | Multiple wood layers bonded with adhesives | Single piece of natural timber |

| Stability | Highly resistant to warping and shrinking | Prone to expansion, contraction, and warping |

| Cost | Generally more affordable | Typically more expensive |

| Appearance | Varied finishes, often looks uniform | Natural grain with unique patterns |

| Durability | Durable, but surface layer can wear down | Long-lasting and can be refinished multiple times |

| Installation | Easier to install, often DIY-friendly | Usually requires professional installation |

| Environmental Impact | Uses less hardwood, eco-friendly options available | Requires harvesting whole timber, less sustainable |

Introduction to Engineered Wood and Solid Wood

Engineered wood consists of multiple layers of wood veneers or fibers bonded together with adhesives, offering enhanced stability and resistance to warping compared to solid wood. Solid wood is milled directly from natural lumber, showcasing unique grain patterns and natural durability but is more susceptible to environmental changes. The choice between engineered wood and solid wood depends on factors like structural requirements, aesthetic preferences, and budget constraints.

Composition and Manufacturing Processes

Engineered wood consists of multiple layers of wood veneers or fibers bonded together with adhesives, providing enhanced stability and resistance to warping compared to solid wood. Solid wood is derived directly from natural timber, retaining its grain and inherent natural properties, but it is more susceptible to environmental changes. The manufacturing process of engineered wood involves assembling and pressing wood components under heat and pressure, while solid wood is primarily shaped through cutting and drying processes.

Durability and Strength Comparison

Engineered wood exhibits enhanced durability and strength due to its layered construction, which resists warping and splitting better than solid wood. Solid wood offers natural strength but is more susceptible to moisture-related damage and dimensional changes over time. Engineered wood's cross-grain design maximizes stability, making it ideal for environments with fluctuating humidity and heavy use.

Aesthetic Differences: Appearance and Finishes

Engineered wood features a consistent grain pattern and smooth surface due to its manufactured layers, allowing for a wide variety of finishes such as veneers and laminates that mimic high-end solid wood. Solid wood displays natural variations in color, grain, and texture, giving each piece unique character and warmth that enhances its aesthetic appeal. Finishes on solid wood often highlight organic imperfections and depth, while engineered wood offers uniformity and design flexibility for contemporary interiors.

Cost Considerations: Engineered vs Solid Wood

Engineered wood generally offers a more cost-effective option compared to solid wood due to its manufacturing process, which utilizes wood veneers and adhesives that reduce material waste and lower production expenses. Solid wood, while often more expensive, provides greater durability and natural aesthetic value, justifying its higher price in premium applications. Budget-conscious projects frequently opt for engineered wood to balance performance with affordability, especially in large-scale construction and flooring.

Environmental Impact and Sustainability

Engineered wood offers a more sustainable option compared to solid wood due to its efficient use of raw materials and ability to utilize fast-growing wood species or wood waste. The manufacturing process of engineered wood typically results in lower deforestation rates and reduced habitat destruction, contributing to a smaller carbon footprint. Solid wood, while durable and renewable, often requires harvesting older trees, which can have a greater environmental impact and slower forest regeneration.

Installation Techniques and Flexibility

Engineered wood offers greater installation flexibility due to its dimensional stability and ability to be installed over various subfloors, including concrete and radiant heating systems. Solid wood requires acclimatization and is sensitive to moisture, limiting its installation options mostly to wood-based subfloors. The precision milling of engineered wood allows for easier click-lock or tongue-and-groove installation methods, reducing labor time and improving overall efficiency.

Maintenance and Longevity

Engineered wood offers superior resistance to moisture and temperature changes, resulting in lower maintenance requirements compared to solid wood. Solid wood demands regular sealing and refinishing to prevent warping, cracking, and insect damage, which can significantly reduce its longevity. Engineered wood's layered construction enhances stability and durability, often extending its lifespan beyond that of traditional solid wood in environments with fluctuating conditions.

Common Applications in Interior and Exterior Design

Engineered wood is widely used in interior applications such as flooring, cabinetry, and furniture due to its stability and resistance to moisture, making it ideal for kitchens and bathrooms. Solid wood remains a popular choice for exterior features like decking, siding, and decorative trims because of its natural durability and aesthetic appeal. Both materials complement modern and traditional designs, with engineered wood offering versatility and solid wood providing authentic texture and strength.

Choosing the Right Wood for Your Project

Engineered wood offers superior dimensional stability and resistance to warping compared to solid wood, making it ideal for areas with fluctuating humidity. Solid wood provides natural beauty and strength, preferred for high-end furniture and structural applications requiring longevity. Selecting the right wood depends on project requirements like durability, cost, and environmental conditions to ensure optimal performance and aesthetics.

Engineered wood vs Solid wood Infographic

materialdif.com

materialdif.com