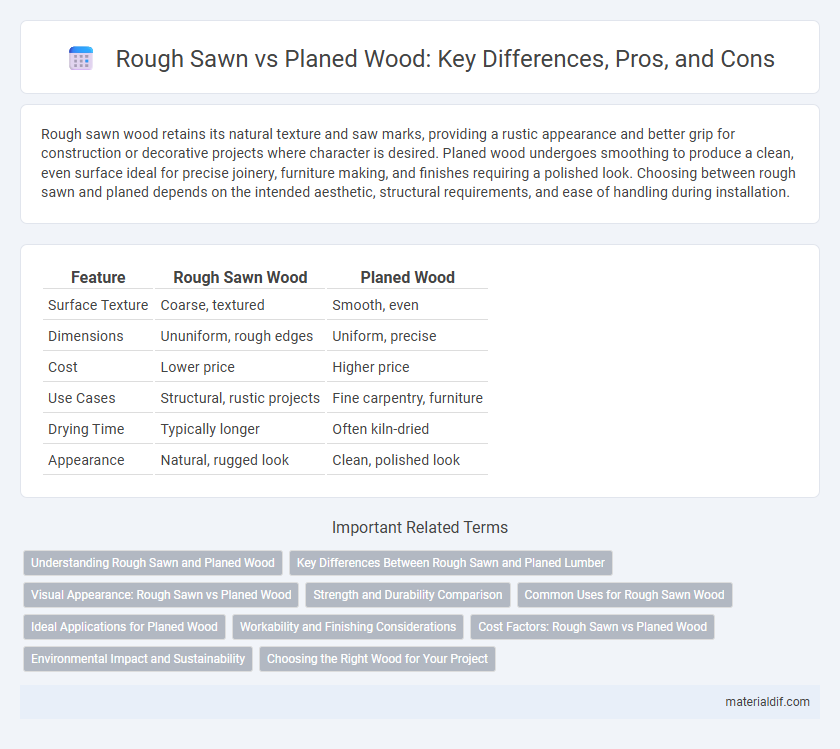

Rough sawn wood retains its natural texture and saw marks, providing a rustic appearance and better grip for construction or decorative projects where character is desired. Planed wood undergoes smoothing to produce a clean, even surface ideal for precise joinery, furniture making, and finishes requiring a polished look. Choosing between rough sawn and planed depends on the intended aesthetic, structural requirements, and ease of handling during installation.

Table of Comparison

| Feature | Rough Sawn Wood | Planed Wood |

|---|---|---|

| Surface Texture | Coarse, textured | Smooth, even |

| Dimensions | Ununiform, rough edges | Uniform, precise |

| Cost | Lower price | Higher price |

| Use Cases | Structural, rustic projects | Fine carpentry, furniture |

| Drying Time | Typically longer | Often kiln-dried |

| Appearance | Natural, rugged look | Clean, polished look |

Understanding Rough Sawn and Planed Wood

Rough sawn wood is lumber cut directly from logs with a sawmill, retaining a coarse, textured surface that requires further finishing for smoothness. Planed wood undergoes an additional milling process with a planer, resulting in smooth, uniform surfaces ideal for immediate use in furniture or construction. Understanding the distinction between rough sawn and planed wood is crucial for selecting the right material based on project requirements for aesthetics and structural precision.

Key Differences Between Rough Sawn and Planed Lumber

Rough sawn lumber is cut directly from logs, retaining a coarse, uneven surface with natural saw marks, while planed lumber undergoes a finishing process to create a smooth, uniform texture ideal for precise construction and furniture making. Moisture content is typically higher in rough sawn wood, affecting dimensional stability, whereas planed lumber is often kiln-dried to reduce shrinkage and warping. The choice between rough sawn and planed lumber impacts both appearance and usability depending on project requirements, cost, and desired finish quality.

Visual Appearance: Rough Sawn vs Planed Wood

Rough sawn wood features a coarse, textured surface with visible saw marks that give it a rustic and natural appearance, ideal for decorative applications requiring an authentic, rugged look. Planed wood boasts a smooth, uniform surface with clean edges, highlighting the wood grain's natural beauty and providing a refined, polished aesthetic suitable for furniture and interior finishes. The choice between rough sawn and planed wood significantly impacts the visual character, influencing design style and project presentation.

Strength and Durability Comparison

Rough sawn wood retains its natural texture and surface irregularities, often resulting in greater dimensional stability and strength due to minimal processing, which preserves the wood's original fibers. Planed wood, while smoother and more aesthetically appealing, undergoes machining that can slightly reduce thickness and remove surface layers, potentially affecting its durability under heavy load conditions. For structural applications requiring maximum strength and long-term durability, rough sawn timber is typically preferred because it maintains the wood's inherent properties better than planed lumber.

Common Uses for Rough Sawn Wood

Rough sawn wood is commonly used in construction, fencing, and outdoor projects due to its durability and natural texture that provides better grip and weather resistance. It serves well in framing, pallets, and rustic furniture where aesthetic uniformity is less critical. The wood's rough surface also enhances paint and stain adhesion, making it ideal for exterior applications.

Ideal Applications for Planed Wood

Planed wood offers a smooth, consistent surface ideal for visible woodworking projects such as furniture, cabinetry, and interior paneling. Its refined finish enhances paint or stain adhesion, making it suitable for decorative and finishing purposes where aesthetics matter. The precision and uniform thickness also support structural applications requiring tight tolerances, like door frames and window casings.

Workability and Finishing Considerations

Rough sawn wood offers superior adhesion for paints and finishes due to its textured surface, making it ideal for rustic or outdoor projects requiring strong grip. Planed wood features a smooth, uniform surface that enhances ease of sanding and staining, providing a refined, professional look for interior furniture and cabinetry. Workability differs as rough sawn wood demands more effort to achieve smooth finishes, while planed wood enables quicker machining and precise joinery.

Cost Factors: Rough Sawn vs Planed Wood

Rough sawn wood typically costs less due to minimal processing and retains a thicker, more textured surface ideal for structural uses. Planed wood undergoes additional machining to achieve a smooth, uniform finish, increasing labor and machinery expenses which raise the overall price. Choosing between rough sawn and planed wood depends on budget constraints and the desired aesthetic or functional application.

Environmental Impact and Sustainability

Rough sawn wood requires less energy during production compared to planed wood, reducing its overall carbon footprint. Its natural texture often eliminates the need for additional finishing treatments that involve chemicals or synthetic materials. Choosing rough sawn wood supports sustainable forestry by minimizing processing waste and promoting the use of all harvested wood components.

Choosing the Right Wood for Your Project

Rough sawn wood retains its natural, textured surface, offering superior grip and a rustic aesthetic ideal for outdoor projects and structural work requiring sturdy, non-slip materials. Planed wood is smoothed by a planer, providing uniform thickness, a polished finish, and ease of painting or staining, making it perfect for indoor furniture and detailed carpentry. Selecting between rough sawn and planed wood depends on project requirements for appearance, function, and finish quality, ensuring optimal performance and visual appeal.

Rough Sawn vs Planed Infographic

materialdif.com

materialdif.com